Garbage transfer bin with intelligent monitoring function

A technology of garbage transfer and intelligent monitoring, applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve problems such as fire prone, affect efficiency, and inappropriate detection, and achieve improved safety, work efficiency, and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

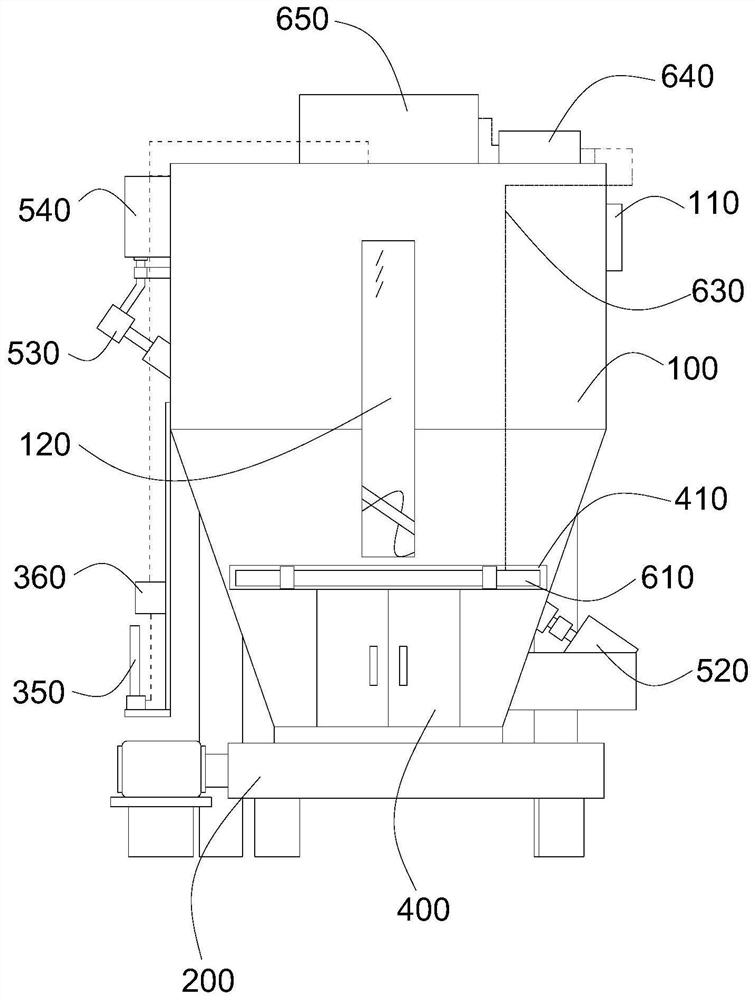

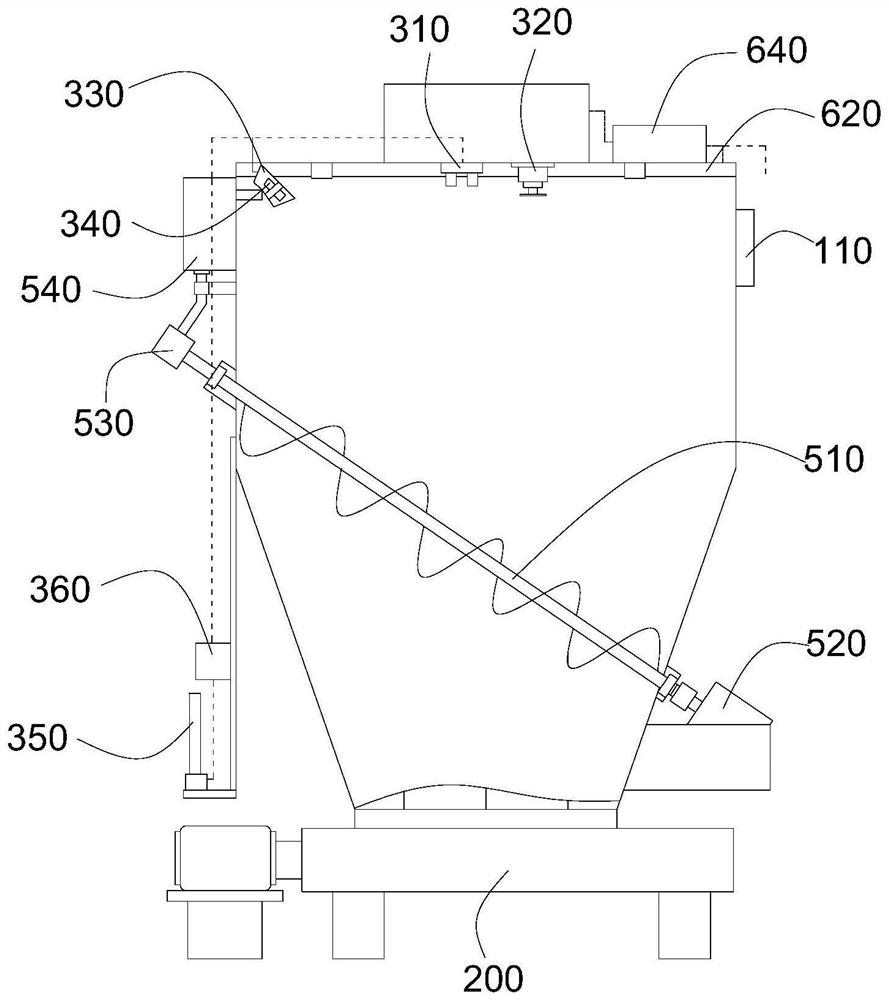

[0020] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses a garbage transfer bin with intelligent monitoring, including a bin body 100 and a screw feeder 200, and the screw feeder 200 is arranged at the bottom outlet of the bin body 100 and communicate with each other; the top inner wall of the warehouse body 100 is equipped with a ranging sensor 310 for monitoring the garbage inside the warehouse body 100, a fire sprinkler device 320, a camera 330, and an infrared temperature measuring probe 340. A display screen 350 and an information processing terminal 360 are installed on the outside of the body 100, the distance measuring sensor 310, the fire sprinkler 320, the camera 330, the infrared temperature measuring probe 340, and the display screen 350 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com