Airtight conveying equipment for dry and wet materials

A technology for airtight conveying and materials, applied in conveyors, transportation and packaging, solid separation, etc., can solve the problem of secondary pollution caused by scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

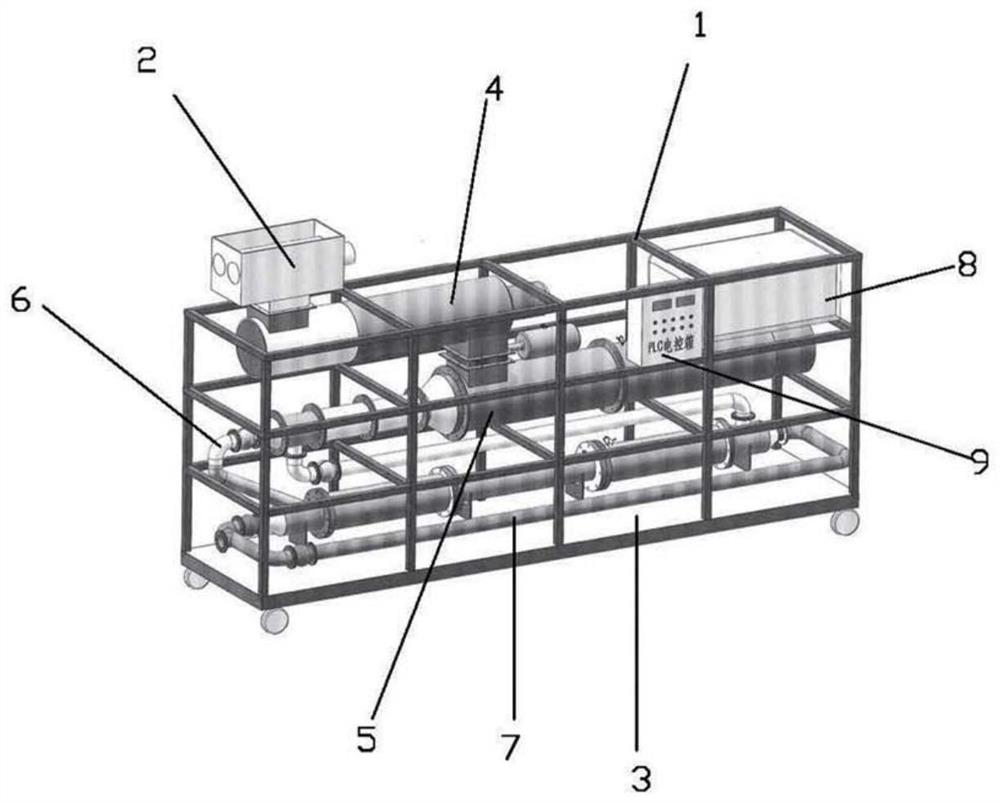

[0023] Such as figure 1 As shown, a closed conveying equipment for dry and wet materials includes a metal frame body 1 in the form of a rectangular parallelepiped. The body 1 includes a hopper 2 placed on the top of the body. The hopper 2 is provided with a roller screen. The lower part of the hopper 2 includes a double-helix special-shaped arch-breaking conveyor 4, a hydraulic cylinder 5 placed at the lower part of the double-helix special-shaped arch-breaking conveyor 4, and a feed pipe 6 connected to the hydraulic cylinder 5, which are placed at the end of the hydraulic cylinder 5 And connected to the feed pipe 7 of the hydraulic cylinder block 5. The bottom of the shown body 1 is provided with a bottom plate 3, and the hydraulic cylinder block 5 and the feed pipe 7 are placed on the bottom plate 3. The body 1 shown includes an oil pump box 8 for the hydraulic cylinder block. The electric control box 9 is placed on the body 1.

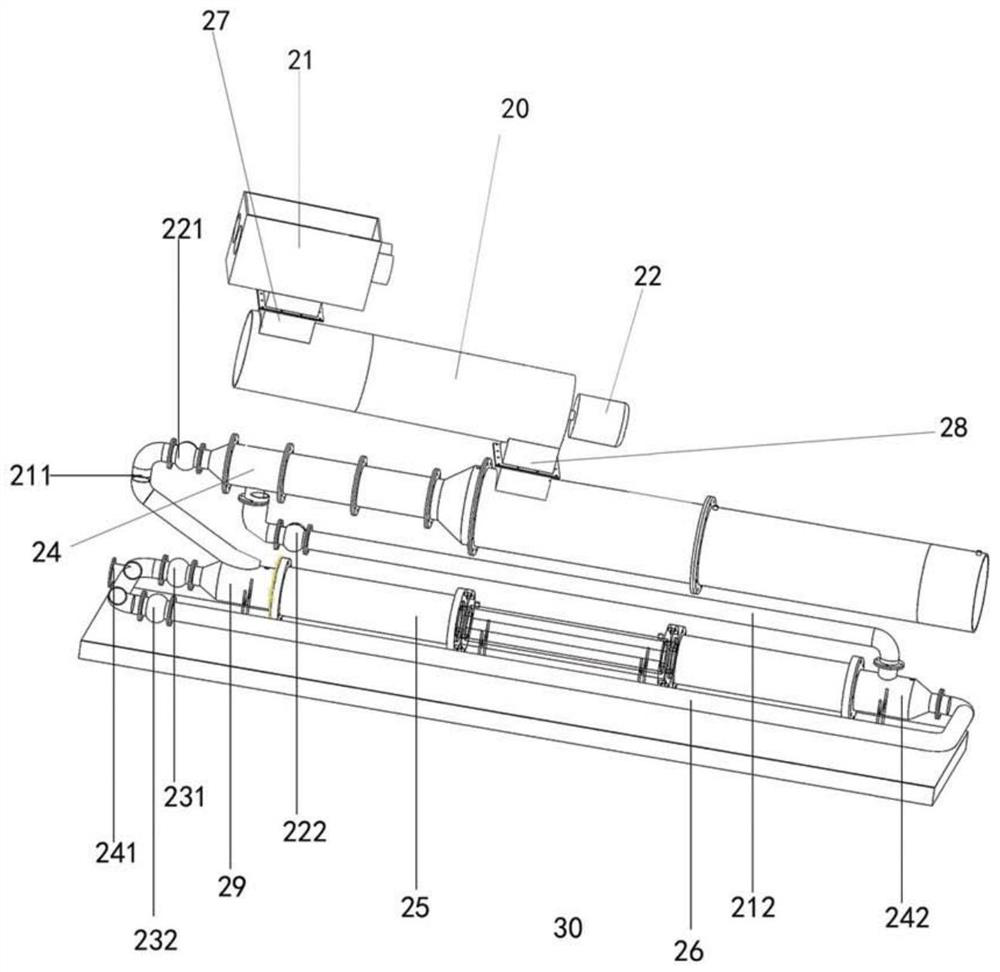

[0024] Such as figure 2 As shown, the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com