Inner-mold contraction type equipment with jacking device and for production of integrated three-grid septic tank

A jacking device and shrinking technology, which is applied in the field of jacking device inner mold shrinking integrated three-compartment septic tank equipment, can solve the problem that the production mold of the integrated three-chamber septic tank is in the semi-mechanical and semi-manual production stage and cannot be large Mass production and other issues, to achieve the effect of easy maintenance, long service life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

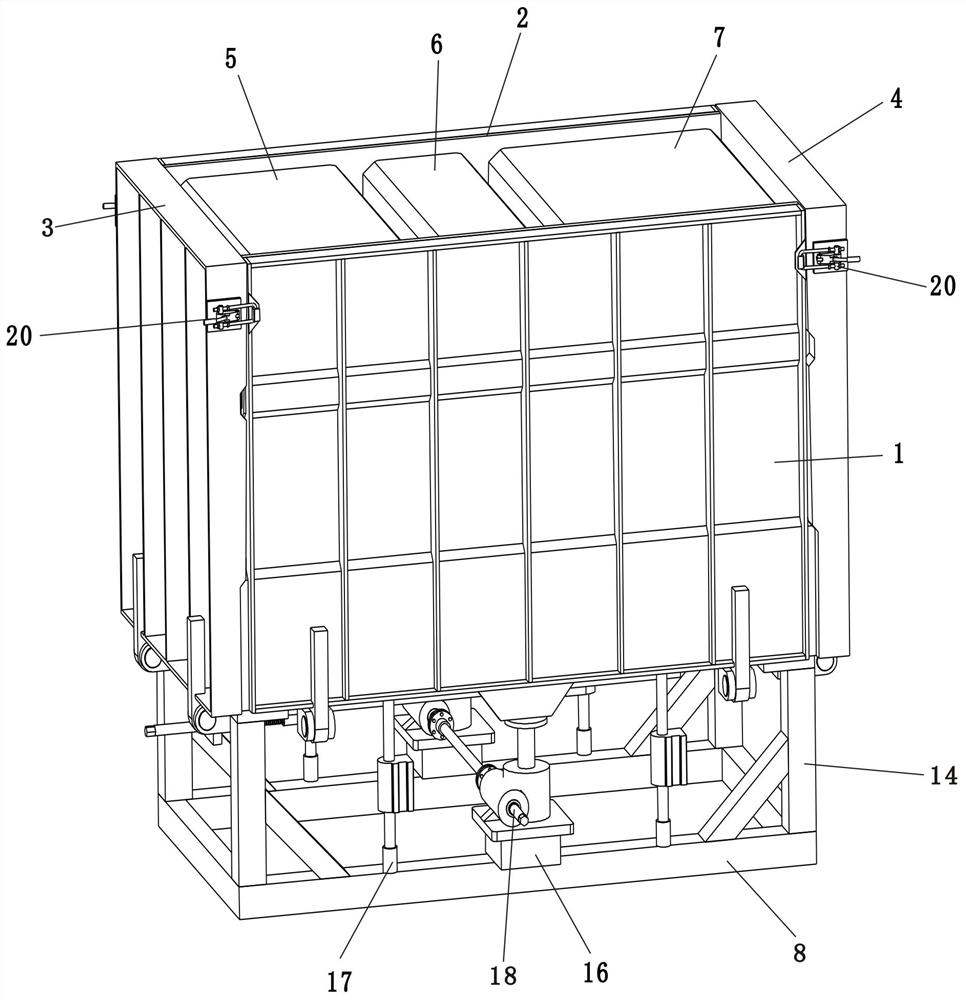

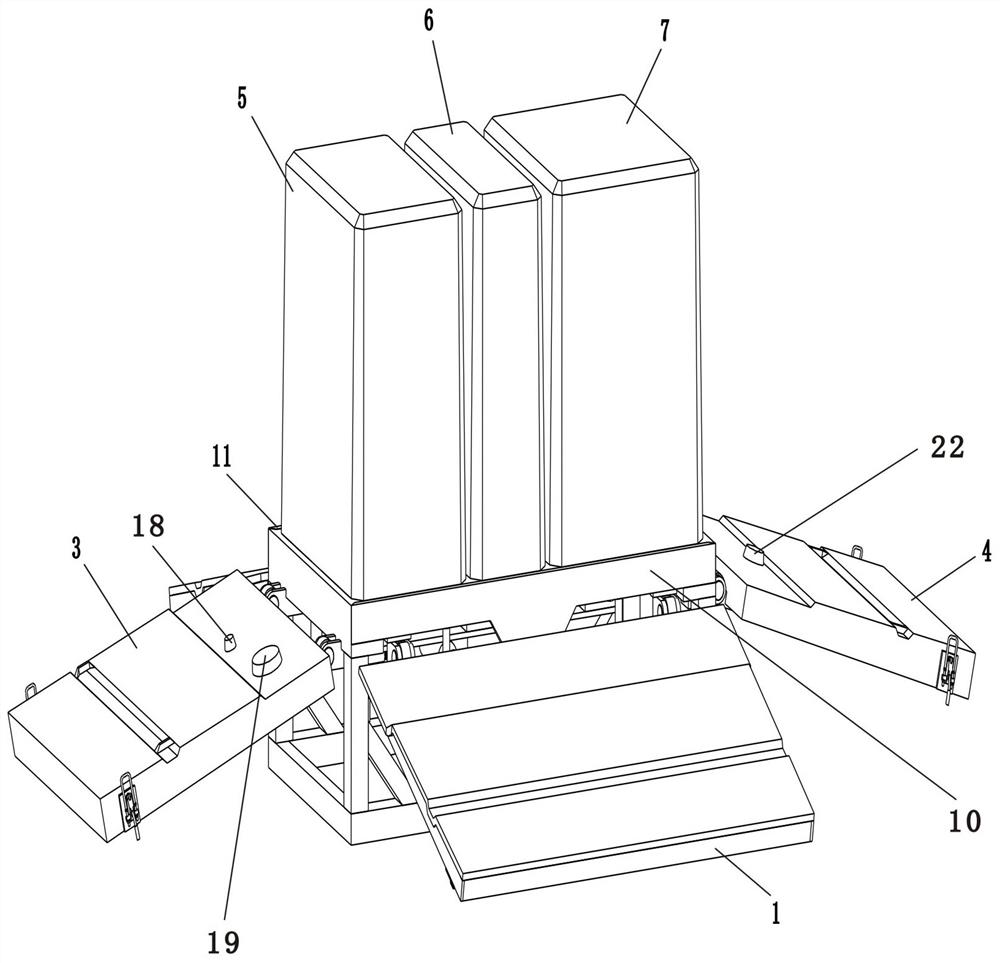

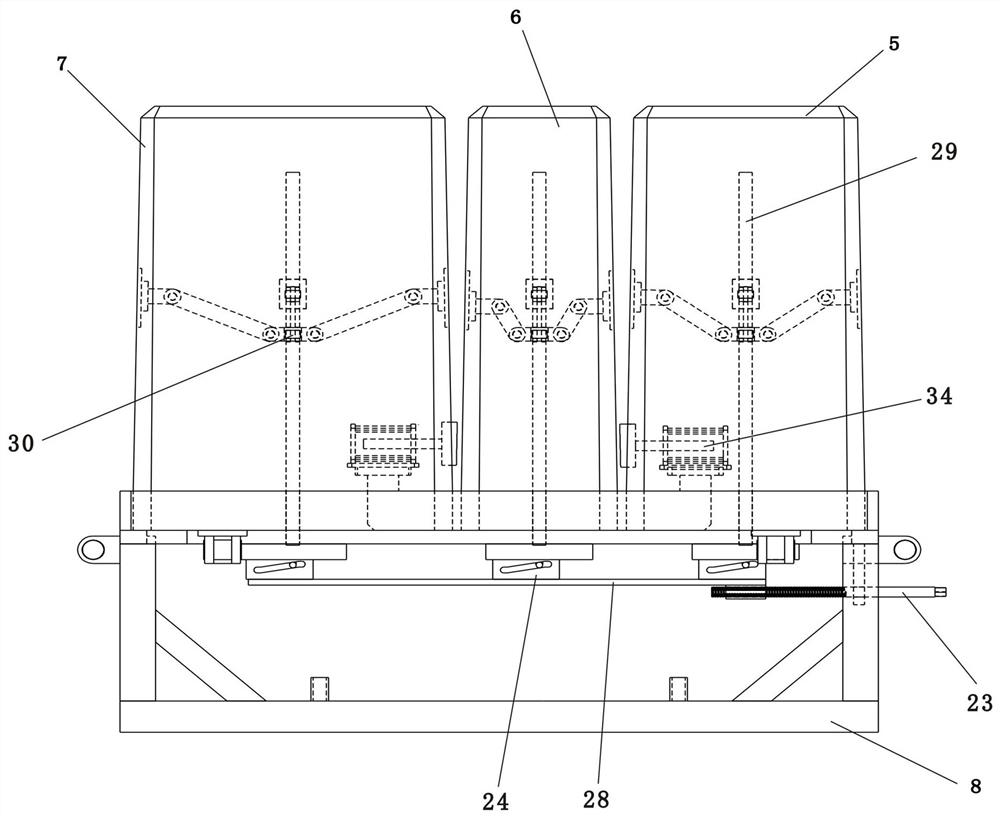

[0018] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown in the three-compartment septic tank equipment of the retractable inner mold of the jacking device, there are front outer formwork 1, rear outer formwork 2, left outer formwork 3, right outer formwork 4, first inner mold 5, second inner mold 6, The third inner mold 7, the lower base 8, the upper base 9, the lower base 8 is a rectangular frame, and the upper base 9 is an elongated frame, and the two frames are connected by four columns 14 into a rectangular base frame, and the upper base 9 is formed by an upper The base girder 12 is connected with some upper base cross beams 13, and the upper base girder 12 is provided with three transmission shaft holes 15, and the first inner mold 5, the second inner mold 6, and the third inner mold 7 are provided with a transmission shaft 29 inside each, and the lower parts are respectively ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap