Matchstick head feeding equipment for matchstick production

A technology of match heads and matches, which is applied in matches and other directions, can solve the problems of low work efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

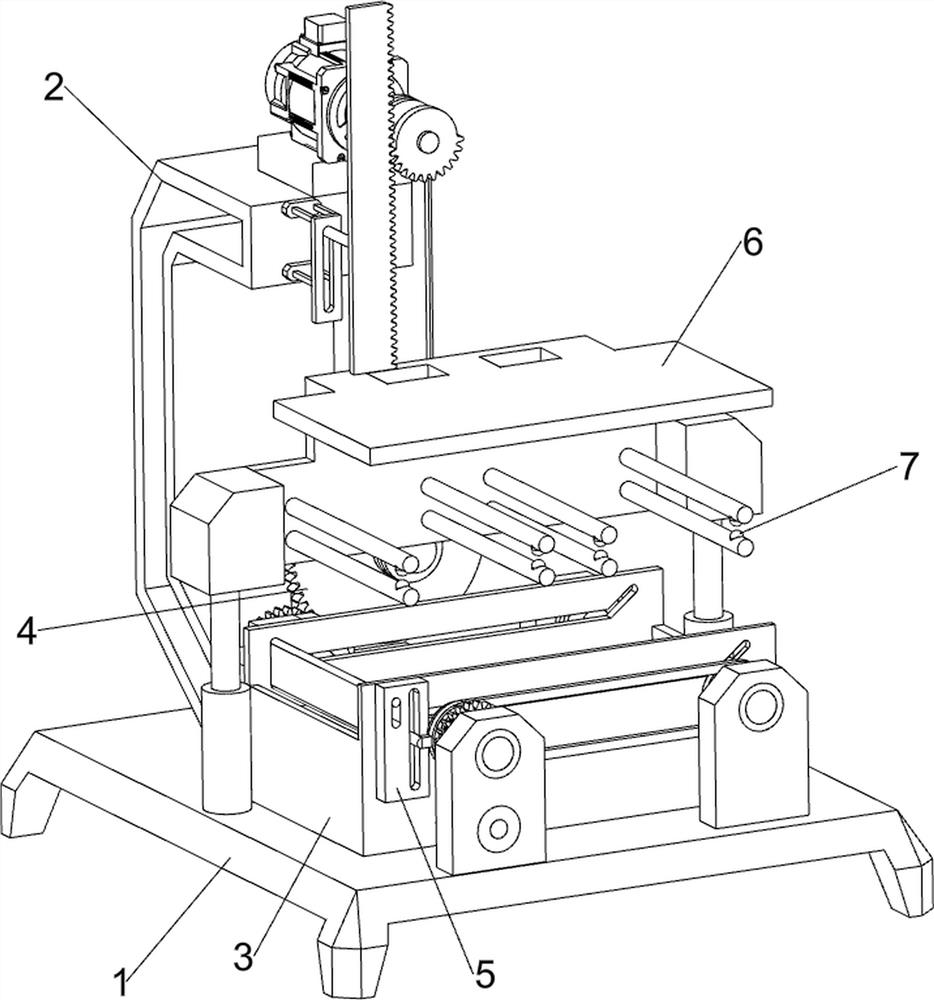

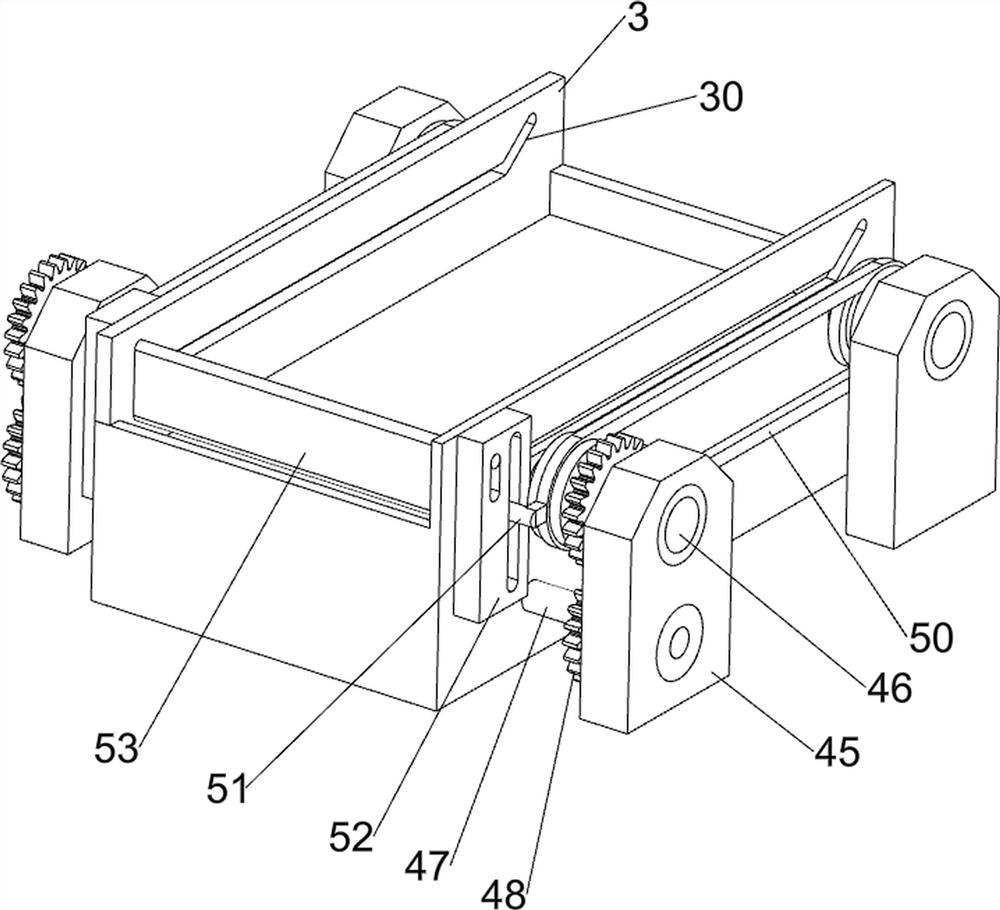

[0023] A matchhead feeding device for match production, such as Figure 1-5 As shown, it includes a base 1, a support frame 2, a discharge box 3, a drive mechanism 4 and a scraper mechanism 5, a support frame 2 is provided on the rear side of the base 1, a discharge box 3 is provided on the front side of the top of the base 1, and a discharge box 3 is provided on the front side of the top of the base 1. Case 3 front and back both sides tops all have guide hole 30, be provided with driving mechanism 4 between support frame 2 tops and base 1 top, discharge box 3 tops and base 1 tops are provided with scraper mechanism 5.

[0024] The staff first fills up the discharge box 3, fixes the match heads on the board, places the board with the match heads on the upper side of the discharge box 3, and then starts the driving mechanism 4 to work, and the driving mechanism 4 drives the scraping mechanism 5 work, and place the matchheads on the discharge box 3 for feeding, and the scraping ...

Embodiment 2

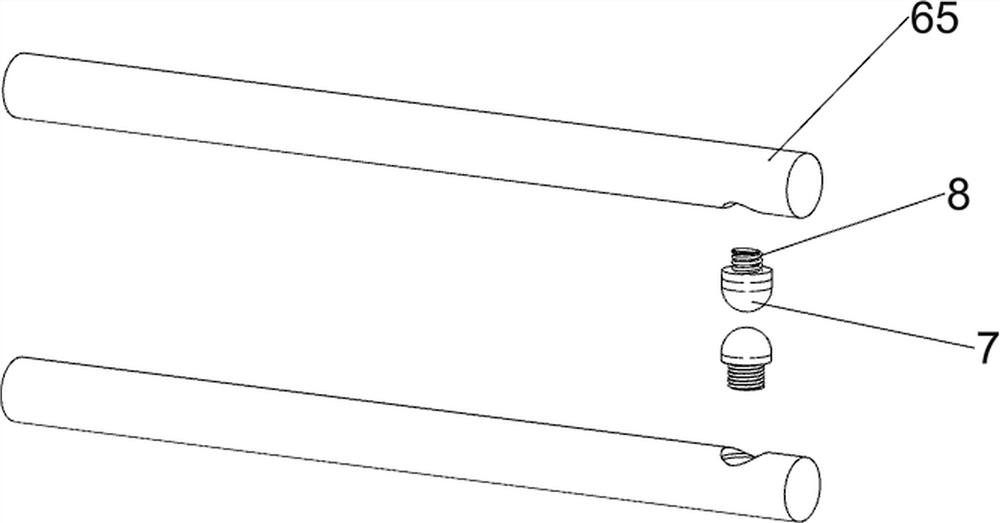

[0030] On the basis of Example 1, such as Figure 6-8As shown, it also includes a pressing mechanism 6, and the pressing mechanism 6 includes a sleeve 60, a first spring member 61, a compression rod 62, a first fixed block 63, a lower pressing plate 64, a support rod 65, a rack 66, a second Two missing gears 67, fixed rod 68, second fixed block 69 and guide block 610, base 1 top, left and right sides are all provided with sleeve 60, all sliding type is provided with compression rod 62 in the sleeve 60, compression rod 62 and sleeve A first spring member 61 is connected between the inner walls of the cylinder 60, a first fixing block 63 is provided on the top of the compression rod 62, a lower pressing plate 64 is arranged between the inner sides of the two first fixing blocks 63, and the rear side of the inner wall of the lower pressing plate 64 is up and down. Four sets of support rods 65 are arranged symmetrically, two support rods 65 form a group, a rack 66 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com