Odor-resistant floor drain

A deodorant and floor drain technology, applied in water/sludge/sewage treatment, drainage structures, buildings, etc., can solve problems such as insufficient fitting pressure, insufficient end face sealing, deodorization of floor drain core, and the effect of reverse overflow function on indoor air quality, etc. To achieve the effect of reducing component wear and fast drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

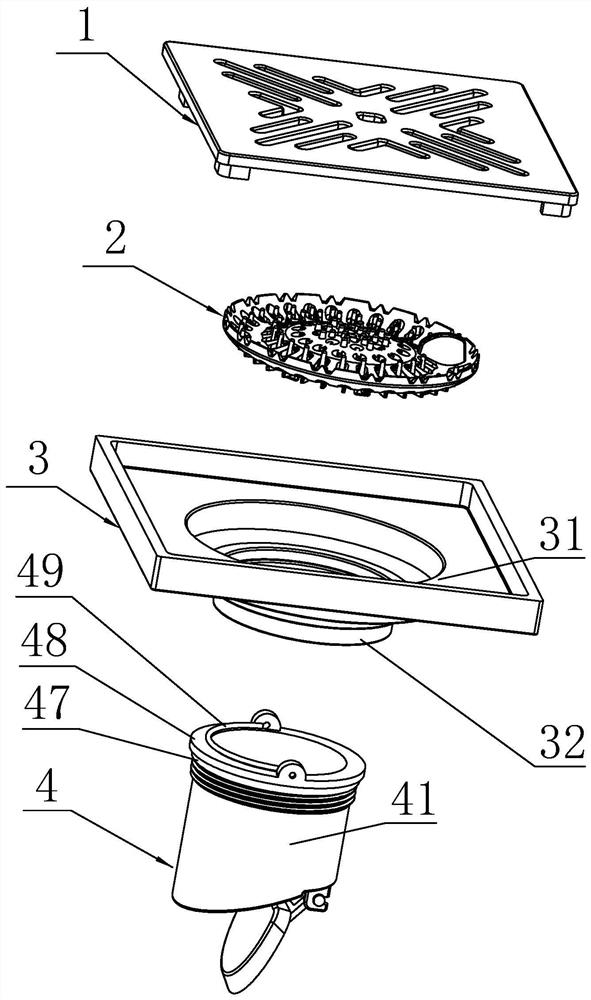

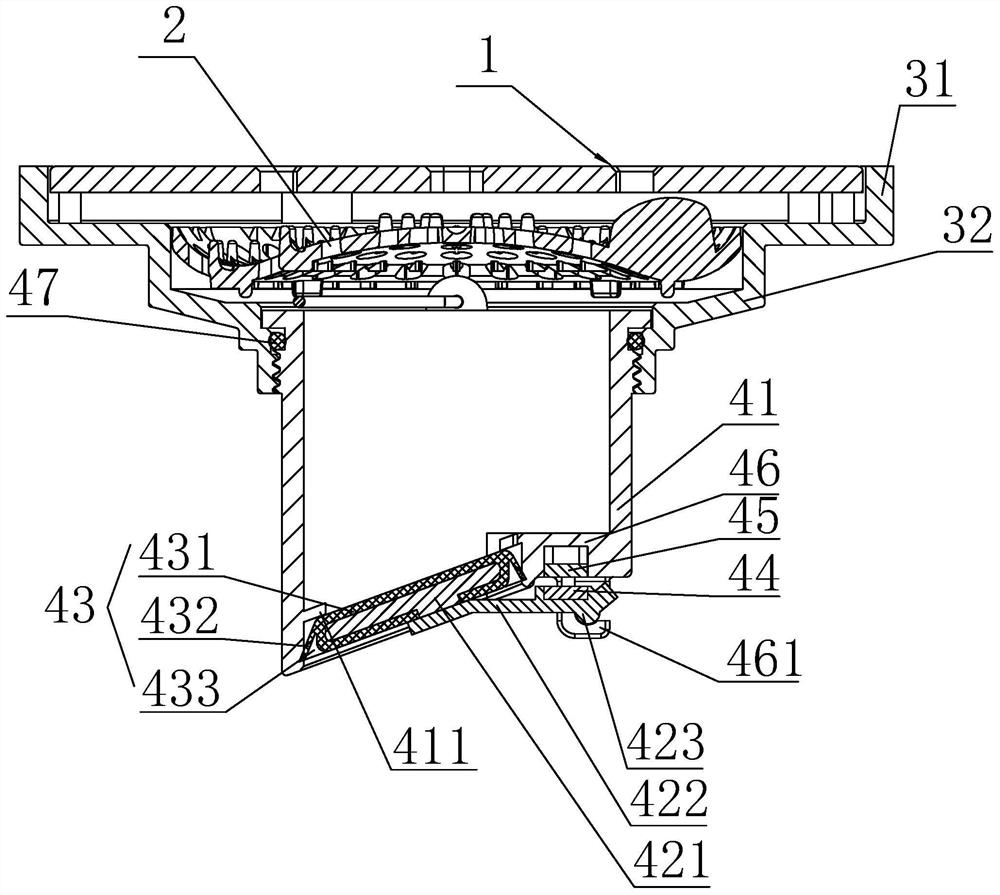

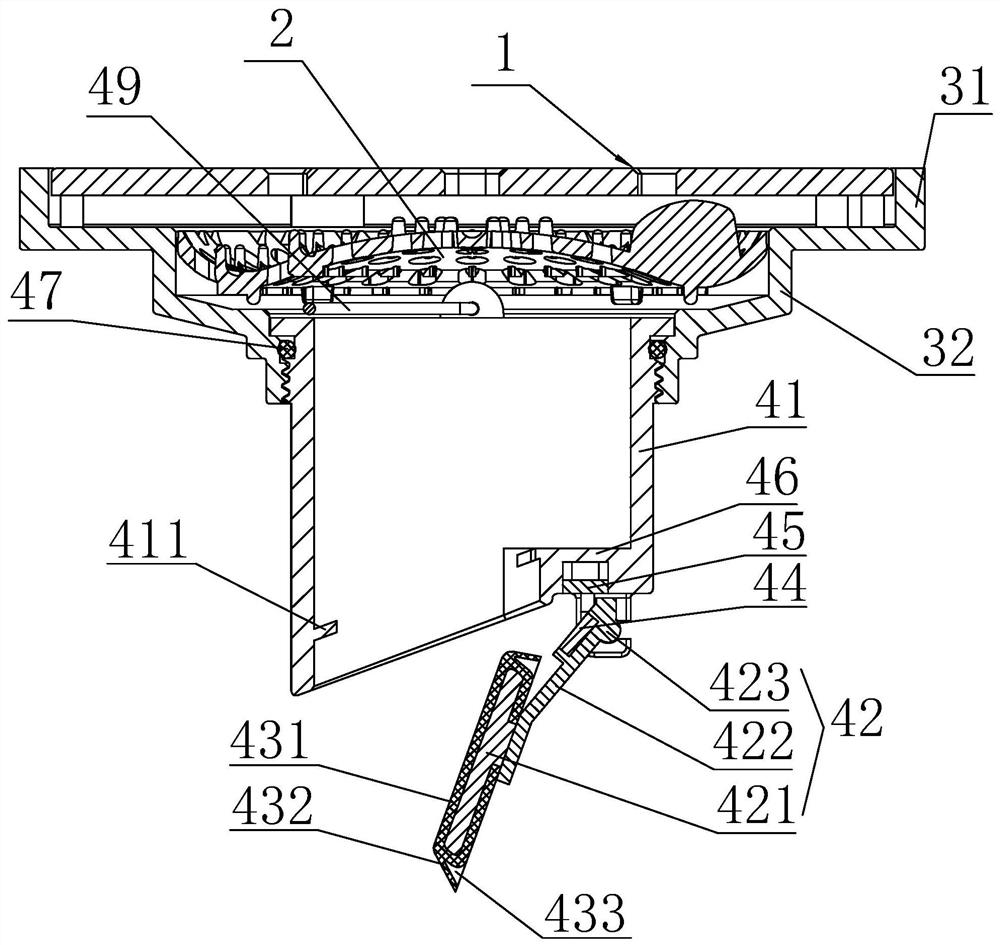

[0034] Such as Figures 1 to 7 As shown, the deodorant floor drain of the present invention includes a face cover 1, a filter screen 2, a floor drain housing 3 and a deodorant core 4.

[0035] The floor drain housing 3 includes an upper housing 31 and a downpipe 32. The deodorant core 4 is arranged at the bottom end of the downwater pipe 32. The deodorant core 4 includes a core housing 41, a flap 42, a seal 43 and a reset mechanism. The plate 42 is pivotally arranged at the water outlet of the core housing 41 , the flap 42 fits the water outlet of the core housing 41 under the action of the reset mechanism, and the flap 42 is connected to the water outlet of the core housing 41 by the sealing member 43 Sealing, the sealing member 43 includes a sealing body 431 and a drainage ligament 432 disposed on the outer periphery of the sealing body 431 , and a hydraulic groove 433 with a notch opening outward is provided between the drainage ligament 432 and the sealing body 431 .

[0...

specific Embodiment 2

[0048] Such as Figures 8 to 10 As shown, the technical feature that distinguishes this embodiment from the specific implementation is that the top view surface shape of the upper casing 31 is elongated. In other embodiments, the top view surface shape of the upper casing 31 can be circular, polygonal, etc. other shapes.

[0049] Specific implementation three:

[0050] Such as Figures 11 to 12 As shown, the technical characteristics of the difference between this embodiment and the specific implementation one are:

[0051] The water pressure groove 433 is arranged on the side wall of the sealing member 43, the notch of the water pressure groove 433 is opened to the side, and the sealing member 43 is fixed on the bottom end of the water outlet of the core housing 41 by encapsulation (in this embodiment, the attached Figure 11 and 12 shown) or the top of the flap 42; when the seal 43 is fixed at the bottom of the water outlet of the core housing 41, when the water overflow...

specific Embodiment 5

[0060] Such as Figure 15 and 16 As shown, the attached figure hides the deodorant core 4. The technical feature of the difference between this embodiment and the specific implementation is that the filter screen 2 includes an arc-shaped portion 21 in the middle and an annular portion 22 positioned around the arc-shaped portion 21. The arc-shaped portion 21 is pivotally arranged in the middle of the annular part 22, and there is a through hole for placing the arc part 21 in the middle of the annular part 22. The through hole is provided with a supporting outer edge, and the diameter gradually increases from top to bottom. The top of the arc part 21 is Arc surface, the bottom of the cover 1 is provided with an arc concave hole 11 matching the top of the arc portion 21, the arc portion 21 is hollow inside, and the bottom surface of the arc portion 21 is fixed with swirl blades 213 along the ring direction. The side wall of the arc portion 21 is provided with grooves, the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com