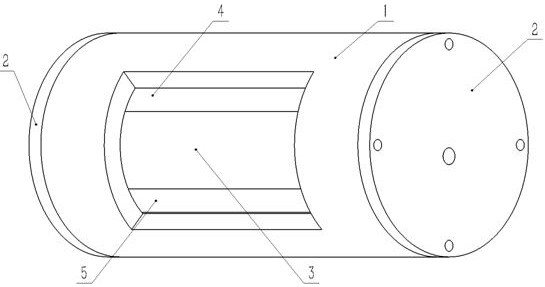

Equidistant vane pump/motor

A vane pump, equidistant technology, applied in the pump/motor field, can solve the problem of insufficient contact between the vane and the shell, and achieve the effect of simple structure and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

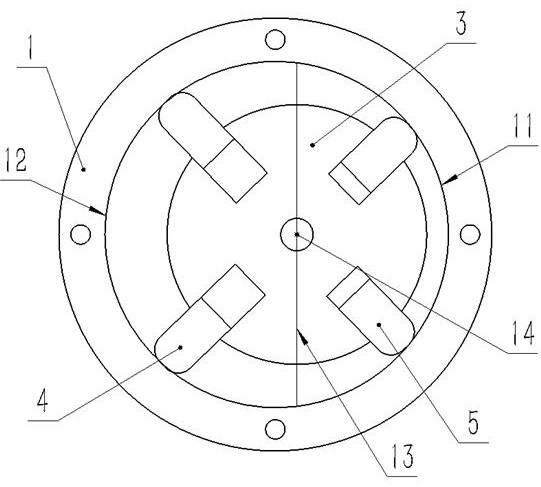

Embodiment 1

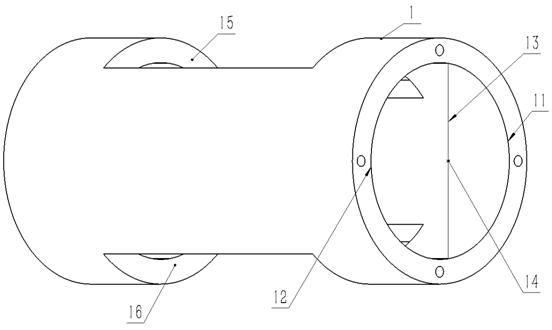

[0022] Such as figure 2 As shown, two opposite first equidistant vanes 4 and two opposite second equidistant vanes 5 form upper, lower, left and right four cavities in the casing 1, and the upper end of the upper cavity is a liquid inlet 15 , the lower end of the lower cavity is the liquid outlet 16, the mandrel rotates counterclockwise, the space of the upper cavity becomes larger, and the liquid is sucked in; the space of the lower cavity becomes smaller, and the liquid is pressed out; the space of the right cavity becomes larger, as the The mandrel rotates counterclockwise, the right cavity communicates with the liquid inlet 15, and the right cavity sucks liquid; the space of the left cavity becomes smaller, and as the mandrel rotates counterclockwise, the left cavity communicates with the liquid outlet 16, and the left cavity The body presses out the liquid; the cycle repeats to realize the function of the isometric vane pump.

Embodiment 2

[0024] Such as figure 2 As shown, two opposite first equidistant vanes 4 and two opposite second equidistant vanes 5 form upper, lower, left and right cavities in the housing 1, and the upper end of the upper cavity is a liquid inlet 15 , the lower end of the lower chamber is the liquid outlet 16. When the liquid inlet 15 is continuously injected with high-pressure liquid, the space of the upper chamber is forced to become larger, and the mandrel rotates counterclockwise; as the mandrel rotates counterclockwise, the left chamber and the liquid outlet 16 is connected to press out the liquid; as the mandrel rotates counterclockwise, the right cavity communicates with the liquid inlet 15, and the right cavity sucks liquid, forcing the space of the right cavity to become larger. The function of the vane motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com