Water gas generator

A generating device, water gas technology, applied in the direction of gasification process, manufacture of combustible gas, gasifier moving parts, etc., can solve the problems of insufficient contact between pulverized coal and water vapor, uneven heating of pulverized coal, etc., to solve the problem of pulverized coal The effect of insufficient contact with water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

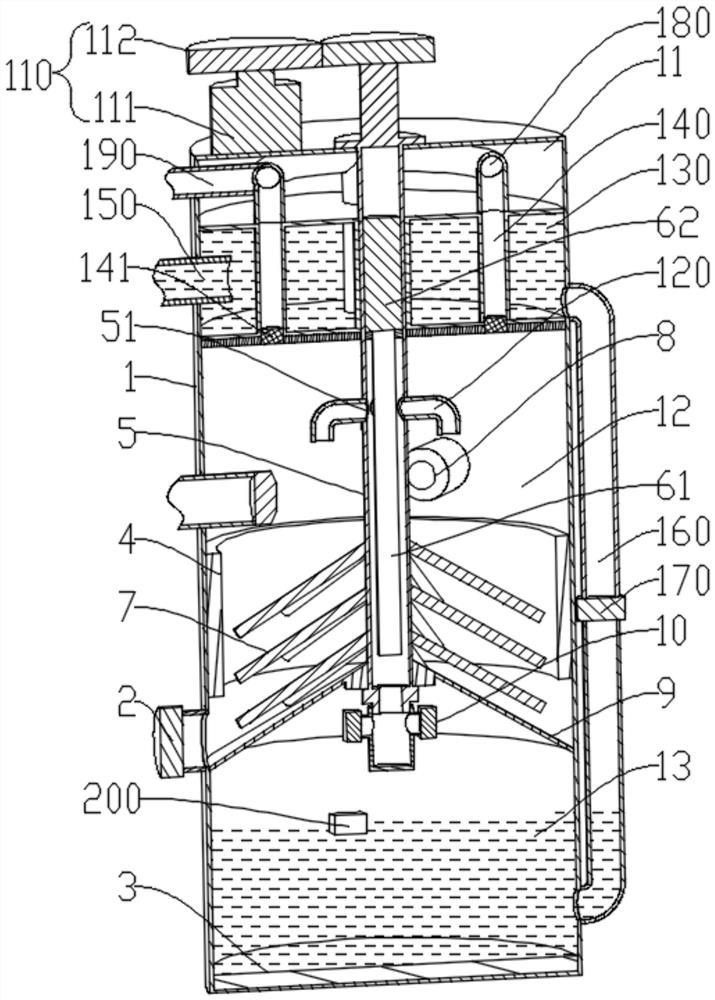

[0018] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] Please also refer to figure 1 , the water gas generating device provided by the present invention is now described. The water gas generating device includes a device main body 1, a first valve 2, a first electric heating block 3, a second electric heating block 4, a stirring tube 5, an air pump 10, an electric heating rod 61, a stirring rod 7, a nozzle 8 and drive mechanism 110 . The main body 1 of the device includes a collection chamber 11, a generation chamber 12 and a steam chamber 13 which are independently arranged in sequence from top to bottom. 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com