Building verticality measuring device

A measuring device and verticality technology, applied in the directions of measuring devices, measuring instruments, surveying and navigation, etc., can solve the problems of time-consuming and energy-consuming, inaccurate floor data collection, lack of ability to adapt to rough and potholes, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A building verticality measuring device, such as figure 1 As shown, it includes a horizontal plate 1, a connecting plate 2, a guide sleeve 3, a drilling mechanism 4 and a measuring mechanism 5. The connecting plate 2 is connected in the middle of the top of the horizontal plate 1, and the left and right sides of the horizontal plate 1 are connected with guide sleeves 3. The top of the guide sleeve 3 is connected with a drilling mechanism 4 , and the top of the connection plate 2 is connected with a measuring mechanism 5 .

[0052] When people need to detect whether the building floor is vertical, people first adjust the height of the parts of the drilling mechanism 4 according to the thickness of the floor, then make the parts of the drilling mechanism 4 fit the bottom surface, and then start the parts of the drilling mechanism 4, Make the parts of the drilling mechanism 4 drill holes on the bottom surface, and the parts of the drilling mechanism 4, the measuring mechan...

Embodiment 2

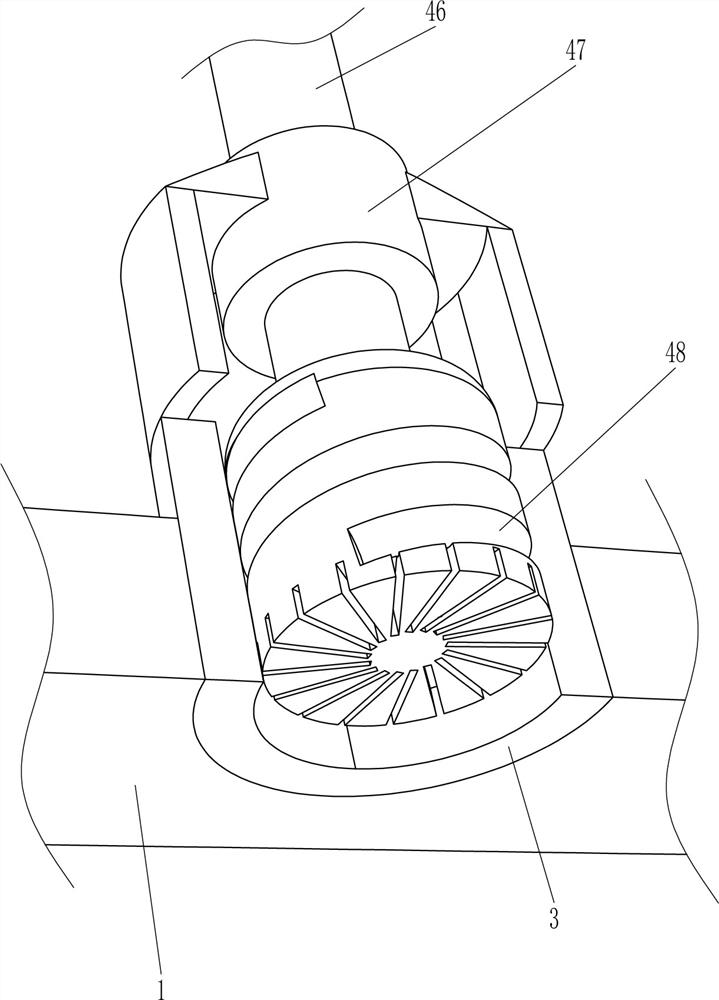

[0054] On the basis of Example 1, such as Figure 1-3 As shown, the drilling mechanism 4 includes a guide rod 41, a damping sleeve 42, an arc rod 43, a fixed ring 44, a drive motor 45, a transmission shaft 46, an anti-deflection sleeve 47 and a flat drill bit 48, and the horizontal plate 1 is connected to the middle part of the rear side. Guide rod 41 is arranged, and damping cover 42 is connected with sliding type on the guide rod 41, and the left and right sides of damping cover 42 fronts are all connected with arc rod 43, and drive motor 45 is all connected on the arc rod 43, and guide sleeve 3 tops The anti-deflection sleeve 47 is connected, and the output shaft of the driving motor 45 is connected with a transmission shaft 46. The lower side of the transmission shaft 46 passes through the anti-deflection sleeve 47 and the guide sleeve 3, and the bottom of the transmission shaft 46 is connected with a flat-bottomed drill bit 48, and the flat-bottomed drill bit 48 passes th...

Embodiment 3

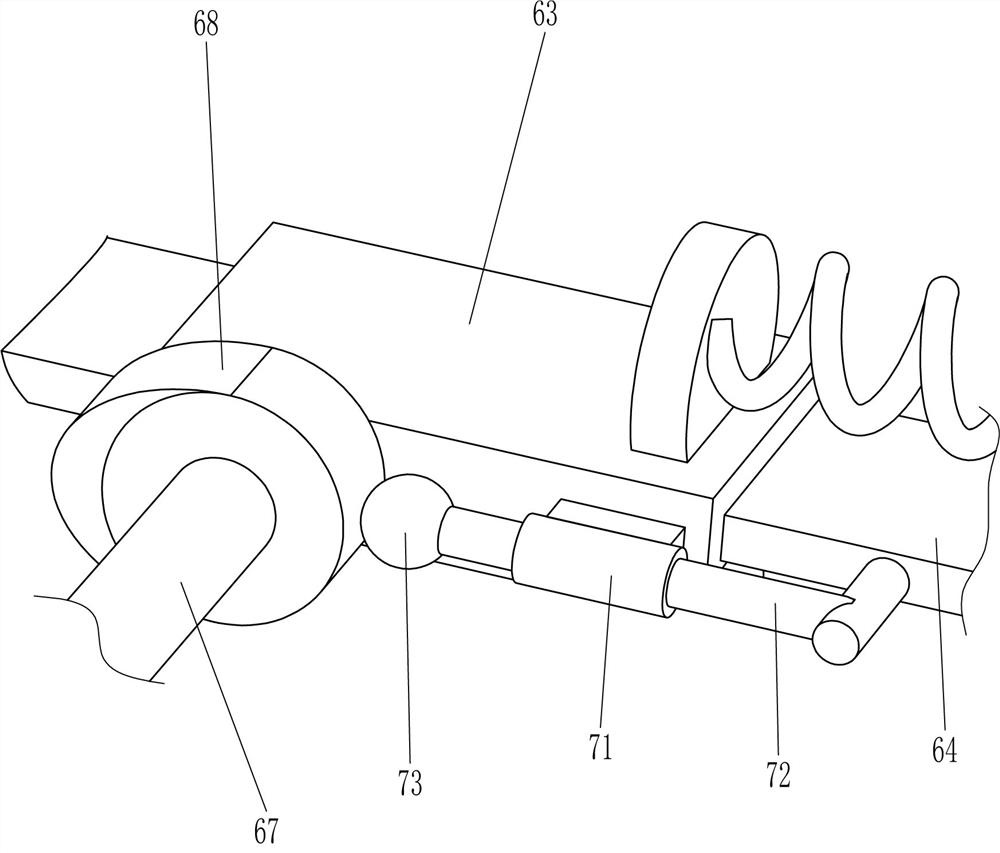

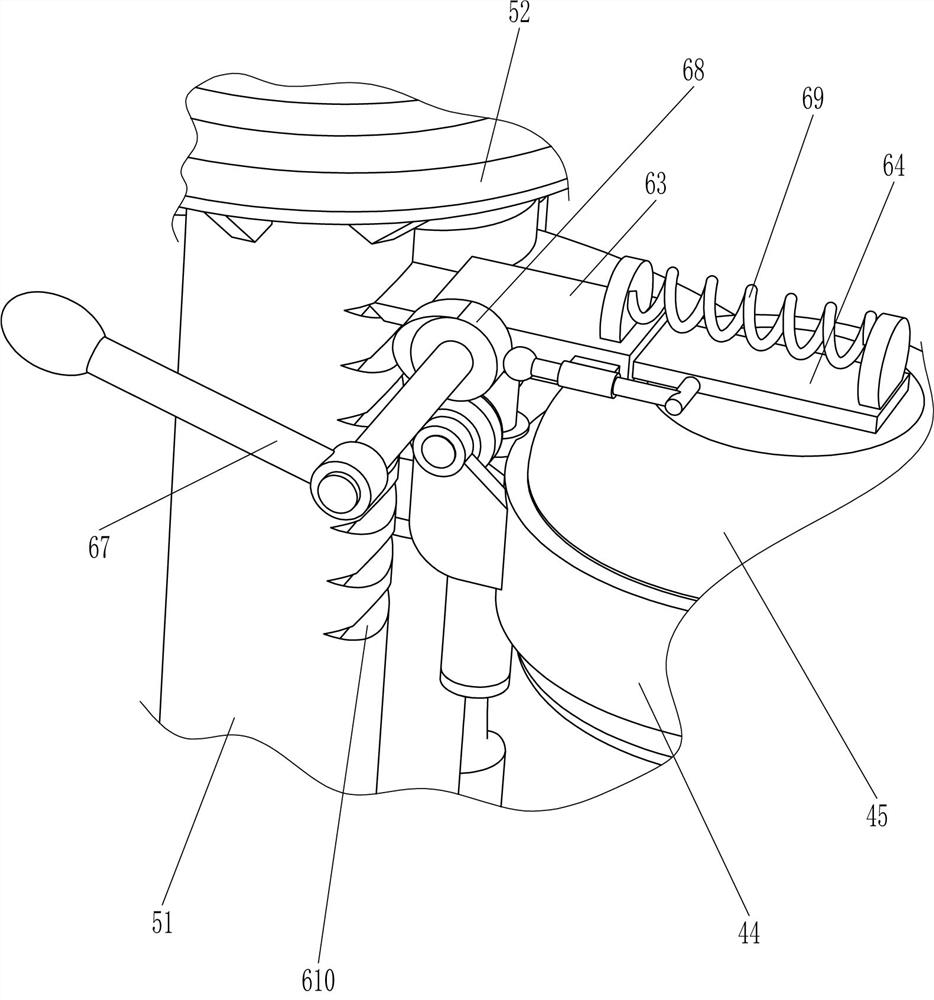

[0059] On the basis of Example 2, such as Figure 4-6As shown, a lifting mechanism 6 is also included, and the lifting mechanism 6 includes a guide tube 61, a slide bar 62, a square hole sleeve 63, a guide plate 64, a support seat 65, a contact wheel 66, a rotating rod 67, a cam 68 and a second spring 69, the left side of the fixed ring 44 on the right side is connected with a guide tube 61, the guide tube 61 is slidably connected with a slide bar 62, the top of the slide bar 62 is connected with a square hole sleeve 63, and the inside of the square hole sleeve 63 is slidably connected with a guide plate 64, the second spring 69 is connected between the right side of the top of the guide plate 64 and the top right side of the square hole sleeve 63, and the right side of the column 51 is evenly provided with a draw-in groove 610, and the draw-in groove 610 is engaged with the left side of the guide plate 64, and fixed The front side of the left part of the ring 44 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com