Positive electrode active material particles for non-aqueous electrolyte secondary battery and production method therefor, and non-aqueous electrolyte secondary battery

A positive electrode active material and non-aqueous electrolyte technology, which is applied in the field of non-aqueous electrolyte secondary batteries, can solve the problems of secondary battery ignition and poor thermal stability, and achieve the effects of small resistance increase, excellent structural stability, and high cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

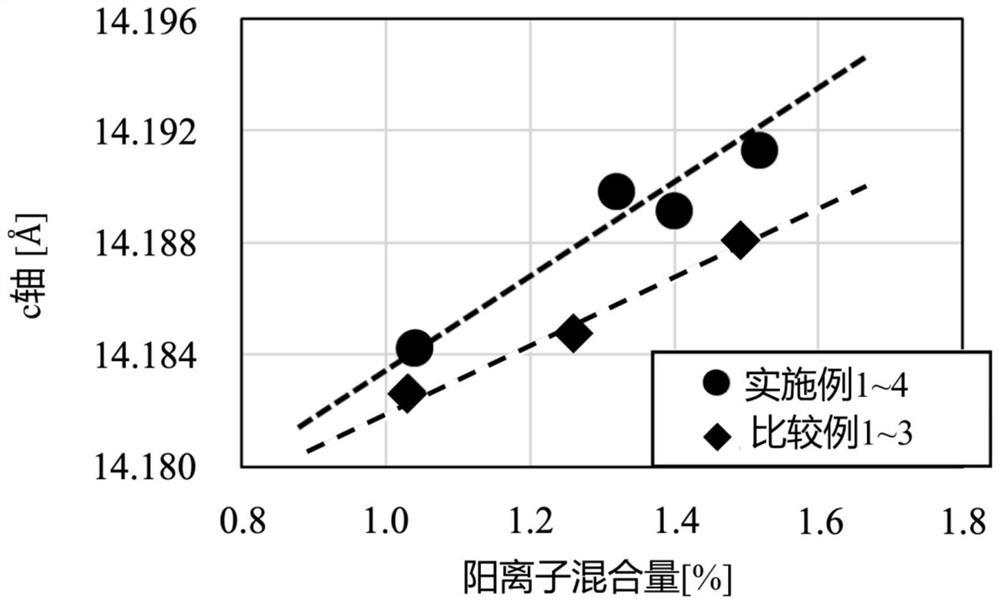

Embodiment 1

[0222] Nickel sulfate aqueous solution, cobalt sulfate aqueous solution, and magnesium sulfate aqueous solution are mixed, make the ratio (molar ratio) of Ni and Co and Mg be Ni: Co: Mg=89.0: 8.5: 0.5, obtain mixed aqueous solution (the amount of Mg is Mg / (Ni+Co+Mg+Al)×100=0.5 mol%). Separated from this mixed aqueous solution, an aqueous sodium aluminate solution was prepared such that the amount of Al was Al / (Ni+Co+Mg+Al) x 100 = 2.0 mol%. In the reaction tank, prepare in advance the pure water 10L that added 300g of sodium hydroxide aqueous solution and ammoniacal liquor 500g as mother liquor, pass through N with the flow rate of 0.7L / min 2 Gas pairing reaction tank for N 2 purge. It should be noted that N 2 purge.

[0223] Then, while rotating the stirring blade at 1000rpm, the above-mentioned mixed aqueous solution, sodium aluminate aqueous solution, sodium hydroxide aqueous solution, and ammonia water were added dropwise at a predetermined speed at the same time, and...

Embodiment 2

[0226] In Example 1, an aqueous nickel sulfate solution, an aqueous cobalt sulfate solution, and an aqueous magnesium sulfate solution were mixed so that the ratio (molar ratio) of Ni to Co to Mg was Ni: Co: Mg=89.0: 8.2: 0.8 to obtain a mixed aqueous solution ( The amount of Mg is Mg / (Ni+Co+Mg+Al)×100=0.8mol%), and the sodium aluminate aqueous solution is prepared so that the amount of Al is Al / (Ni+Co+Mg+Al)×100=2.0mol %, react under the same conditions as in Example 1, and synthesize the precursor compound. Except for this, positive electrode active material particles as a layered lithium composite oxide were obtained in the same manner as in Example 1.

Embodiment 3

[0228] In Example 1, an aqueous nickel sulfate solution, an aqueous cobalt sulfate solution, and an aqueous magnesium sulfate solution were mixed so that the ratio (molar ratio) of Ni to Co to Mg was Ni:Co:Mg=89.0:8.0:1.0 to obtain a mixed aqueous solution ( The amount of Mg is Mg / (Ni+Co+Mg+Al)×100=1.0mol%), and the sodium aluminate aqueous solution is prepared so that the amount of Al is Al / (Ni+Co+Mg+Al)×100=2.0mol %, react under the same conditions as in Example 1, and synthesize the precursor compound. Except for this, positive electrode active material particles as a layered lithium composite oxide were obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com