Air cooling module mechanical locking design method

An air-cooled module and mechanical locking technology, which is applied to mechanical equipment, friction-clamped detachable fasteners, connecting components, etc. Check and verify the mechanical strength of the cold module to avoid damage to the board and facilitate installation and locking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

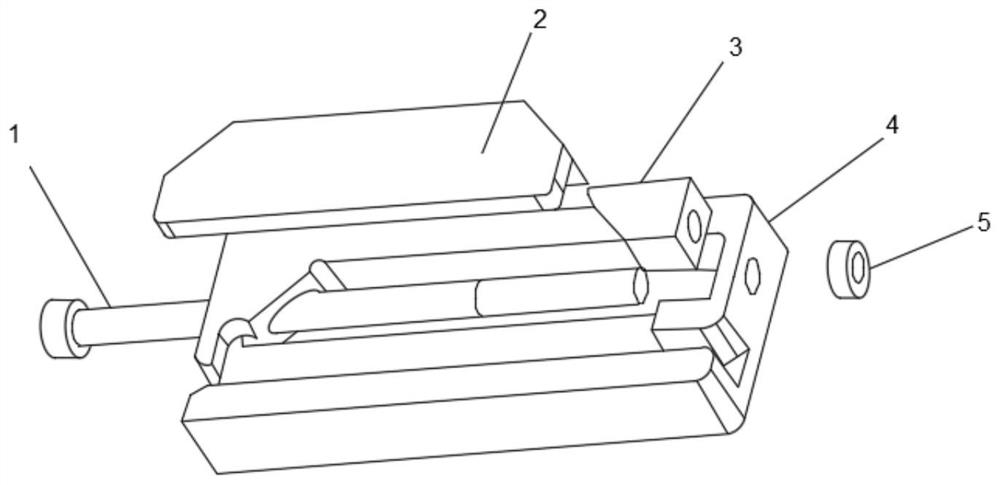

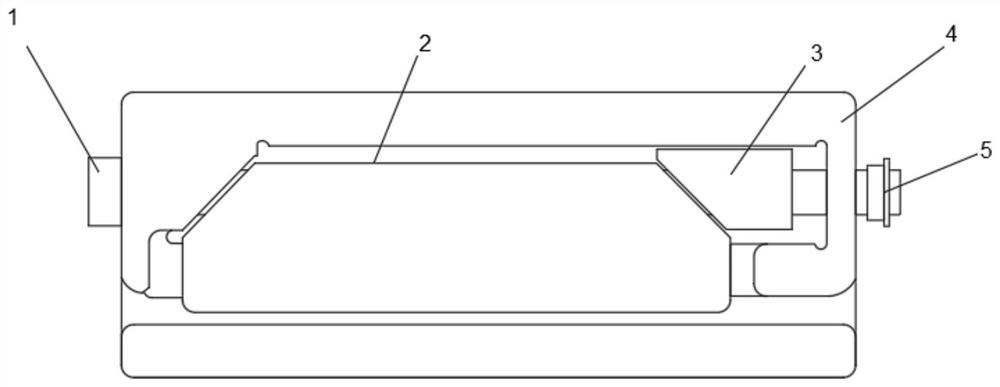

[0020] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical solutions: a mechanical locking design method of an air-cooled module, including an air-cooled sub-box and a locking mechanism, and the locking mechanism is composed of a push screw 1, a clamping block 2, Block 3, locking box 4 and anti-loosening nut 5 consist of the following steps:

[0021] Step 1: First assemble the air-cooled subrack side panels, horizontal connecting rails, and plug-in board guide rails, and insert the air-cooled module into the chassis;

[0022] Step 2: Use a screwdriver to rotate the propulsion screw 1, and the propulsion screw 1 drives the extrusion block 3 to squeeze the clamping block 2 along the horizontal direction of the screw, and the clamping block 2 moves along the inclined plane to press against the air-cooled module.

[0023] Wherein, a small hole is drilled on both sides of the lock box 4, and a push screw 1 is interspersed between the holes on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com