Patents

Literature

46results about How to "Convenient and quick operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

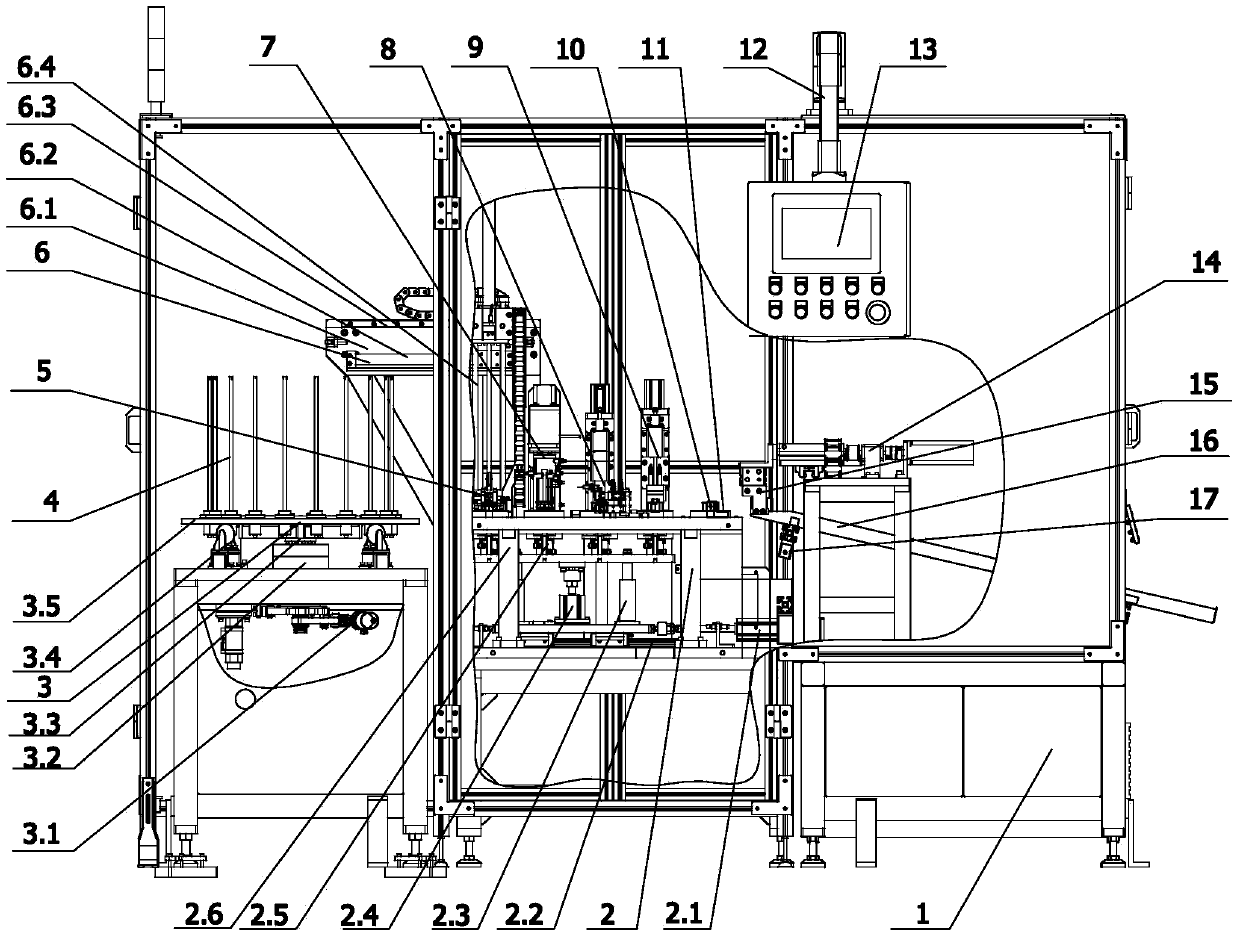

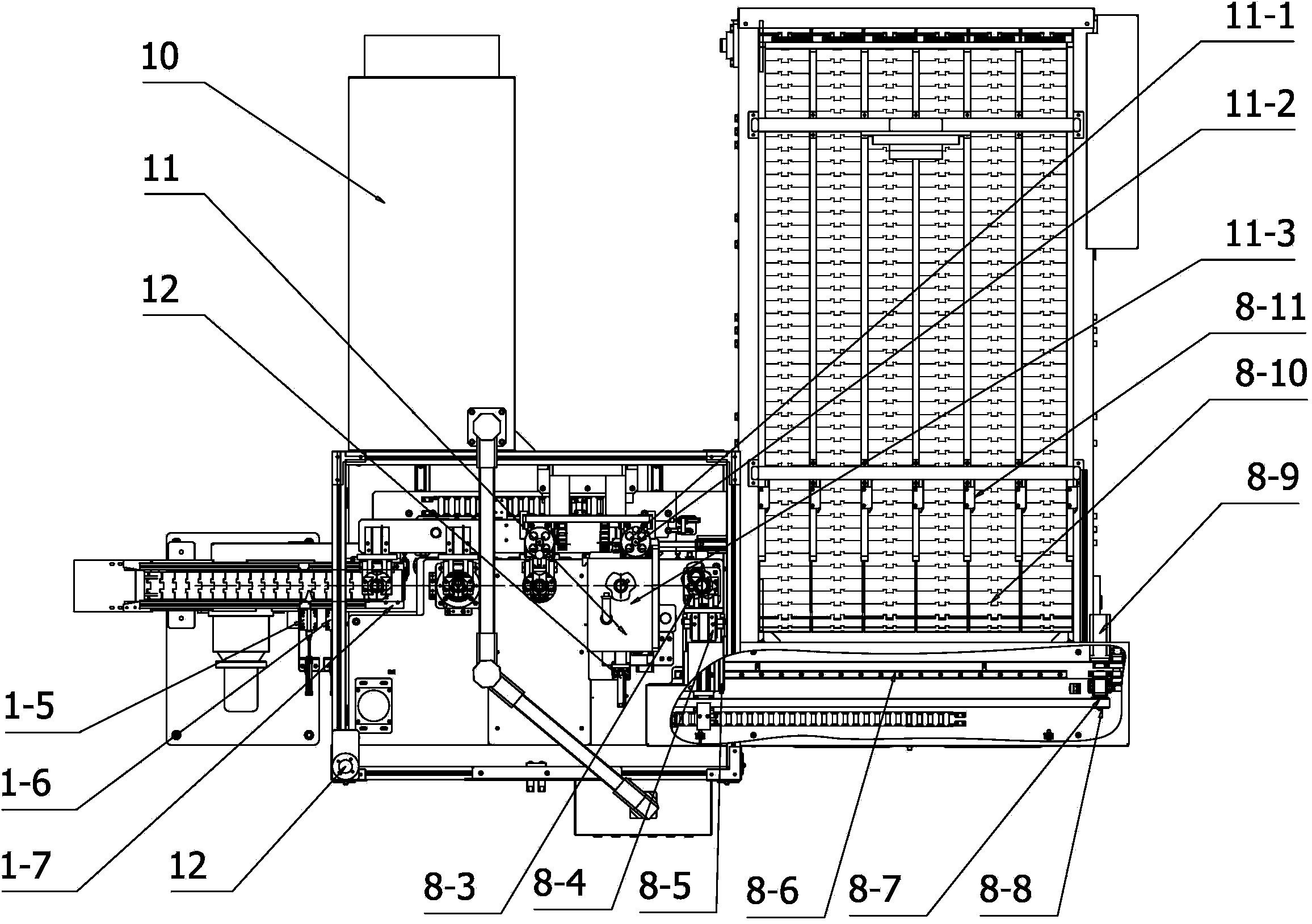

Full-automatic rotor measuring machine

ActiveCN103471542ARealize automatic crawlingRealize group storageMeasurement devicesGroove widthEngineering

The invention relates to a full-automatic rotor measuring machine, in particular to a measuring machine which can achieve measuring and grouping workpieces of the same specification in the same position and different groups in the production process of a rotor of an automobile steering vane pump according to the thicknesses and the groove widths, and the measuring machine has the functions of automatically achieving measuring and grouping of the workpieces. The measuring machine comprises a rack, a feeding stepping mechanism, a feeding stepping rotary material disc, feeding rods, a feeding mechanical arm, a material moving mechanism, a rotating positioning mechanism, a groove width measuring mechanism, a thickness measuring mechanism, an optical fiber sensor, a discharging station, an alarm light, an operation box, a servo motor movable grouping mechanism, a discharging mechanical arm, a gravity material channel, a alarm switch for the full state of material and an electronic control cabinet. The feeding stepping rotary material disc is arranged on the left portion of the rack, and the multiple feeding rods are connected to the feeding stepping rotary material disc. The full-automatic rotor measuring machine achieves automatic grabbing, automatic material moving, automatic recognizing and automatic storing in groups of the workpieces and automatically achieves measuring and grouping of the workpieces.

Owner:WUXI MEASURE MACHINE MFR

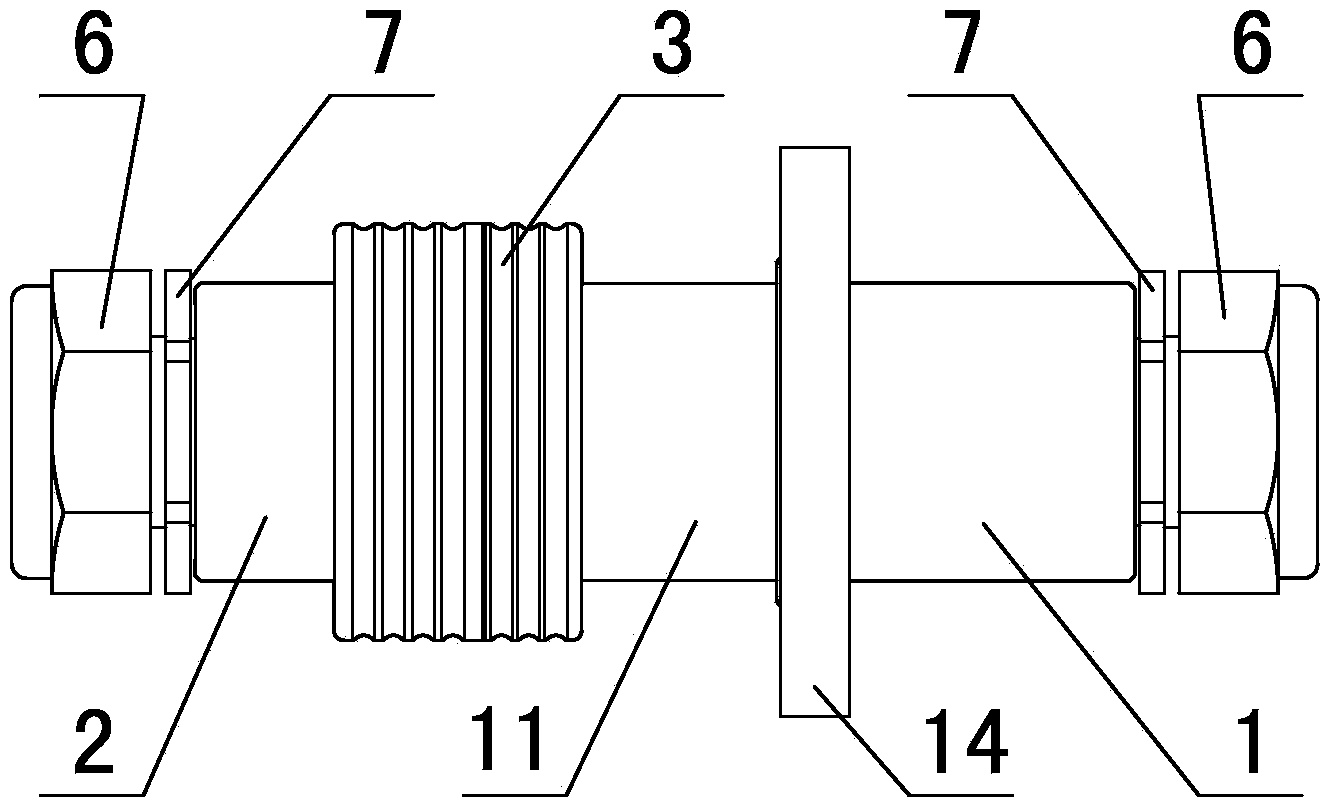

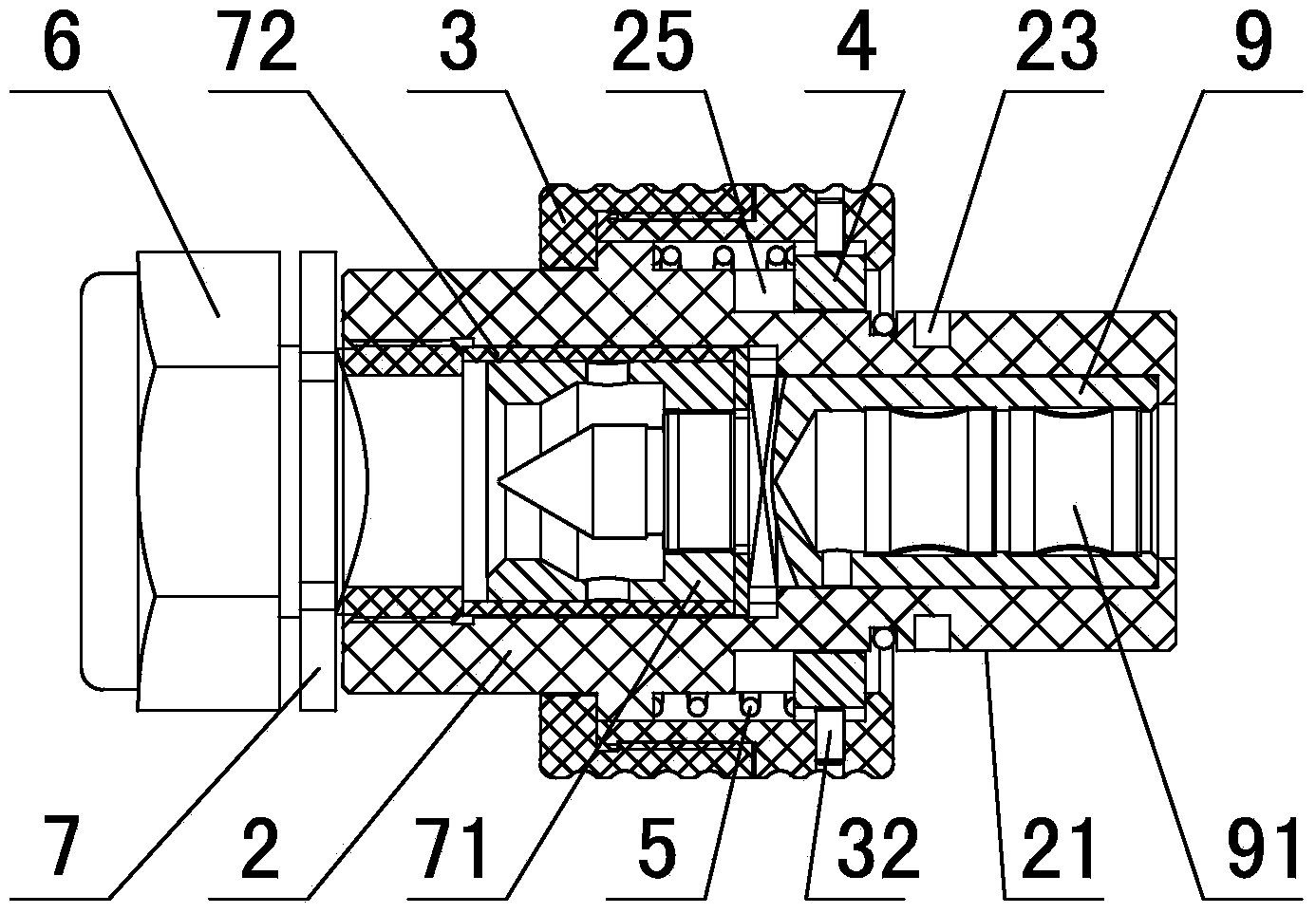

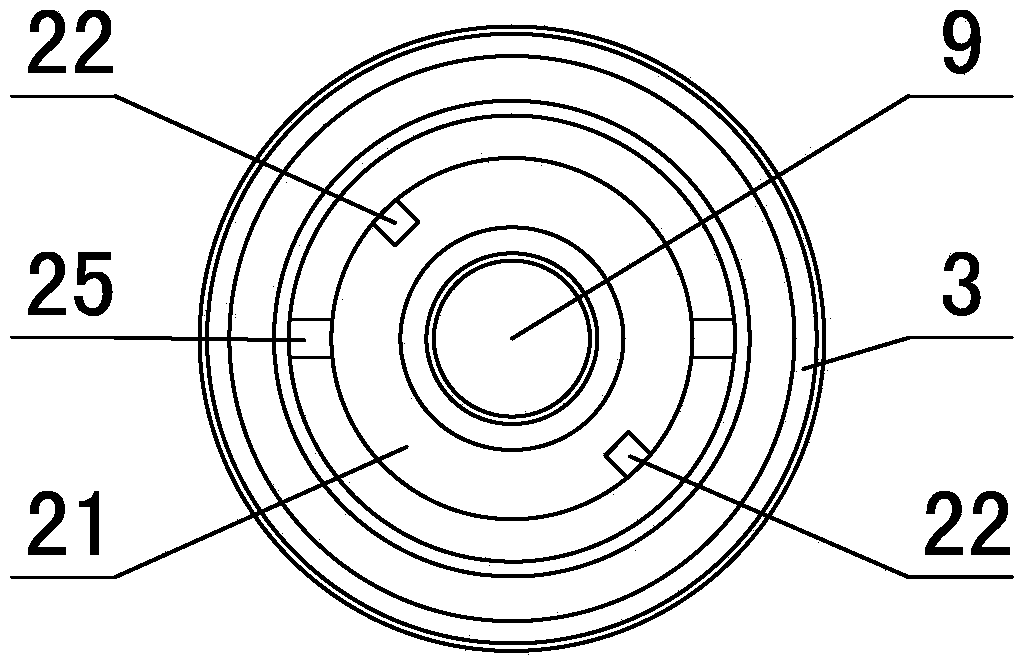

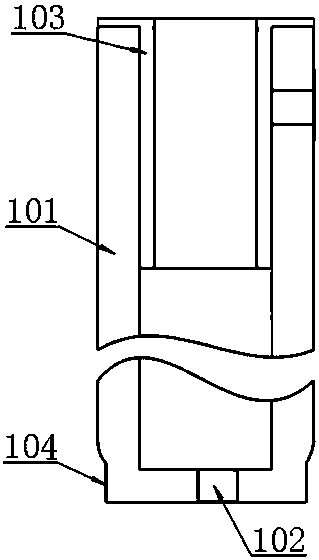

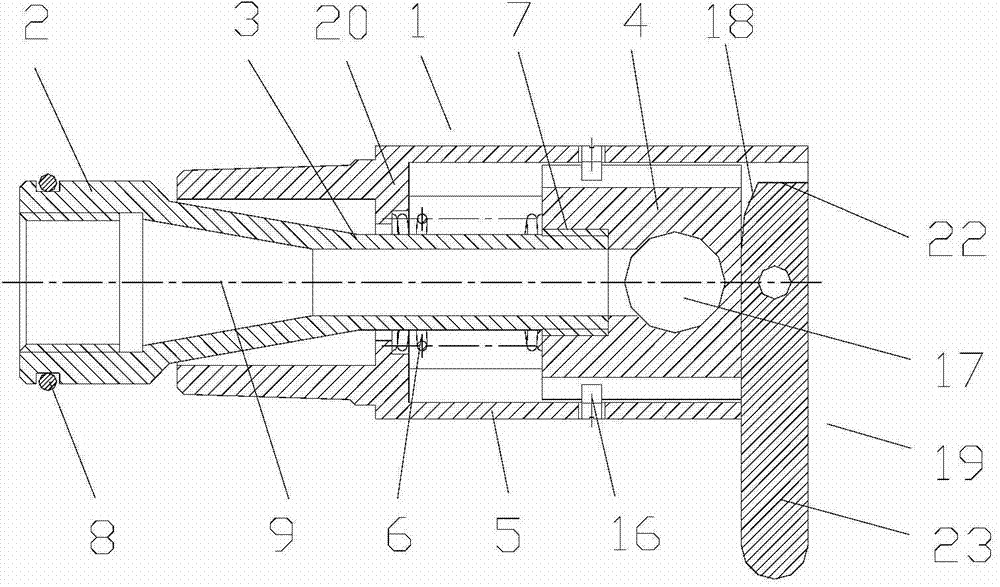

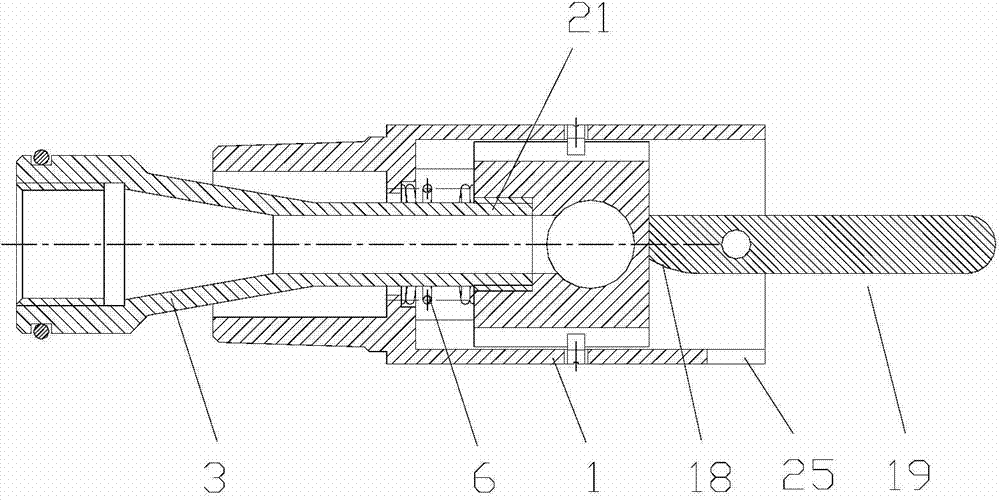

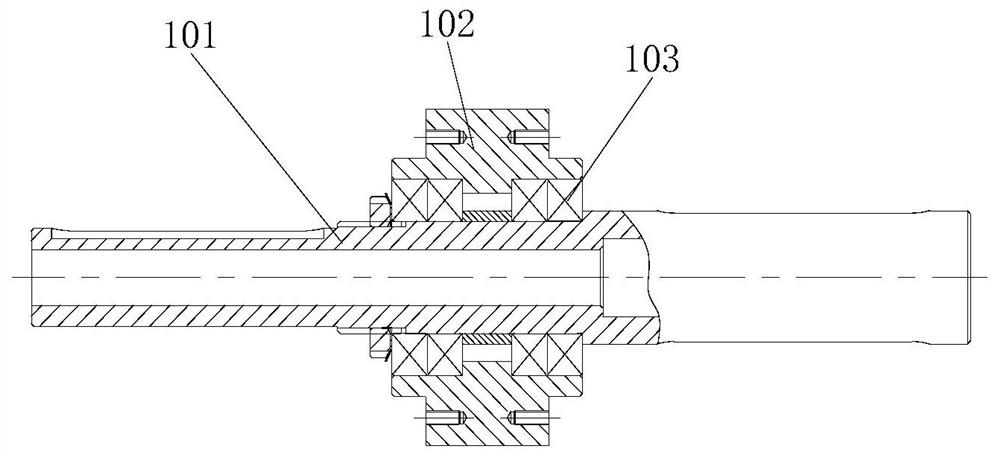

Rapid locking-disengaging coupling element

ActiveCN103594866AFirmly connectedSimple structureCoupling device detailsTwo-part coupling devicesCouplingEngineering

The invention discloses a rapid locking-disengaging coupling element. L-shaped grooves are formed in the outer wall of a cylindrical plug-in portion of a plug, clamping screws are convexly arranged on the inner wall of the cylindrical front shell of a plug-in base, positioning grooves are formed in an protruding ring at the rear end of the plug-in portion, key grooves are formed in the front end of the plug-in base, a blocking ring is convexly arranged at the rear end of the protruding ring, the periphery of the blocking ring is sleeved with a sliding sleeve, a locking sleeve is arranged between the sliding sleeve and the protruding ring, key strips are arranged in the locking sleeve, and a spring is arranged between the locking sleeve and the blocking ring. When the plug and the plug-in base are in the locking state, the clamping screws are located at the tail end of the L-shaped grooves, the front portions of the key strips on the plug are located in the key grooves in the plug-in base, and the rear portions of the key strips are located in the positioning grooves in the plug. The rapid locking-disengaging coupling element is simple in structure, convenient to operate, capable of achieving rapid locking and disengaging of a connector, and high in use value.

Owner:ZHEJIANG ZHONGHANG ELECTRONICS

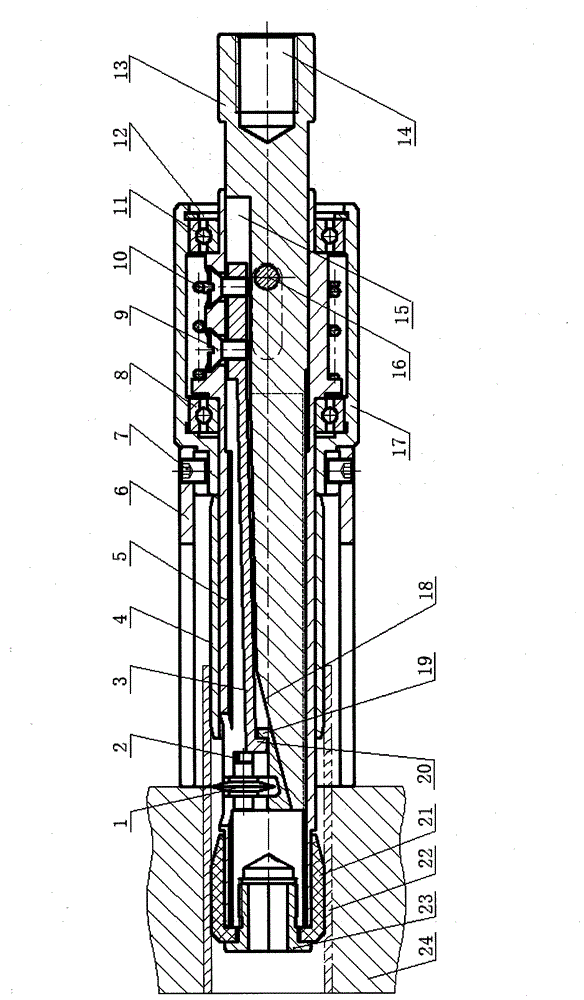

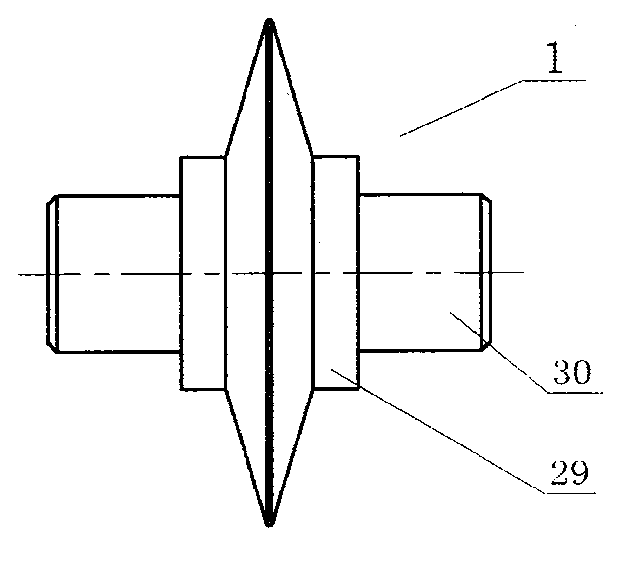

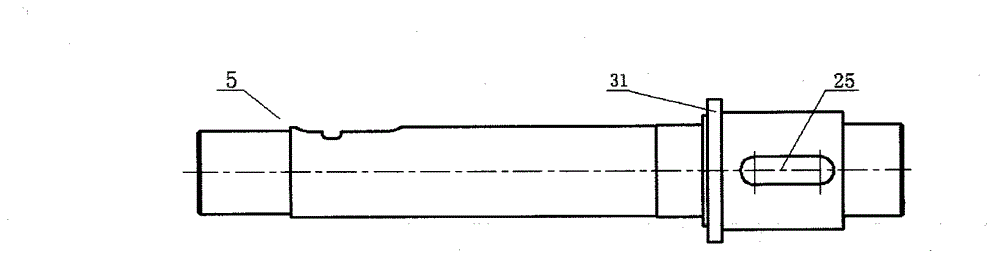

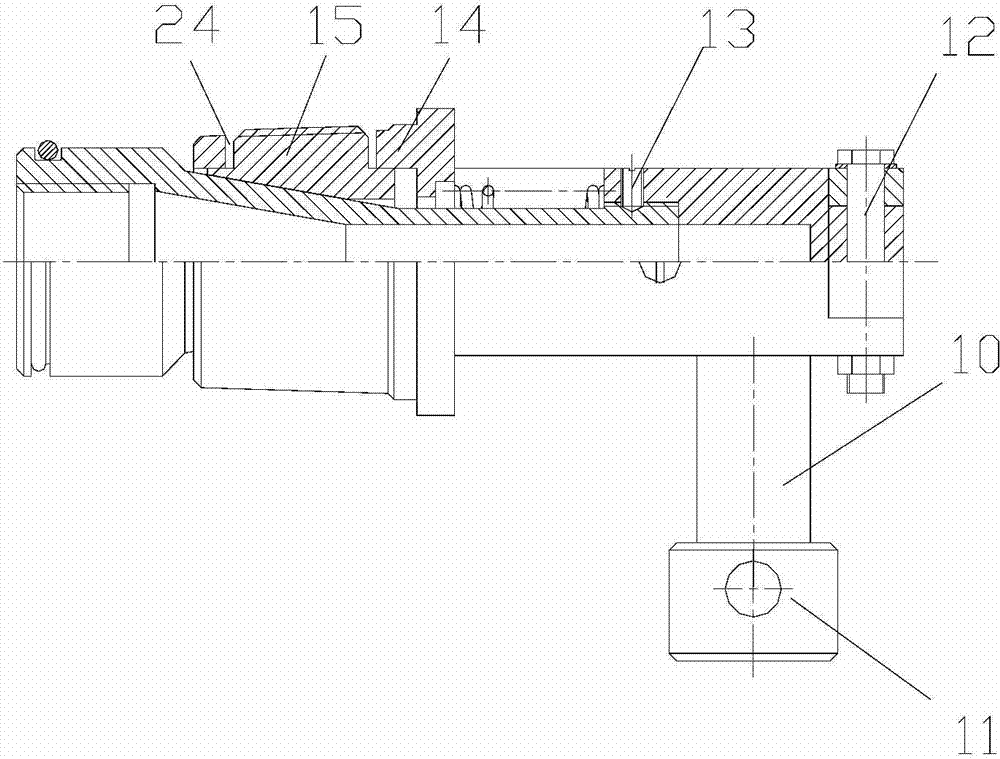

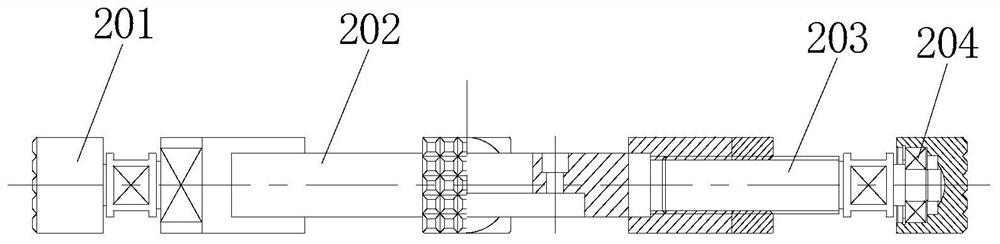

Pipe cutter

InactiveCN103056438ACompact structureReasonable designTube shearing machinesShearing toolsEconomic benefitsHooking

The invention relates to a pipe cutter. The pipe cutter comprises a cutter bar and a cutter rest, wherein the cutter bar is installed in a hollow cavity of a keeping sleeve and provided with a groove on the upper portion, a plate spring is connected with the keeping sleeve through a screw, a long and round through hole is arranged on the wall of the keeping sleeve between a left rolling bearing and a right rolling bearing, a spring is sleeved outside the keeping sleeve, a blind hole with threads is arranged on the right side of the cutter bar, a cutter rest leaning slope is arranged on the left side, the cutter rest leans against the cutter rest leaning slope, a round cutter is mounted on the cutter rest, and a cutter rest hook is arranged at the right end and connected with a plate spring hook arranged at the left end of the plate spring in a hooking mode. The pipe cutter is simple in structure and compact in structure, reasonable in design, capable of bearing large load, safe and reliable; cleaning operation is not needed due to scrap-free cutting, operating processes are reduced, no scrap scratches inner walls of pipes, the cutting quality is high, the service life is long, and high economic benefits are provided.

Owner:HARBIN TIANTAI TECH

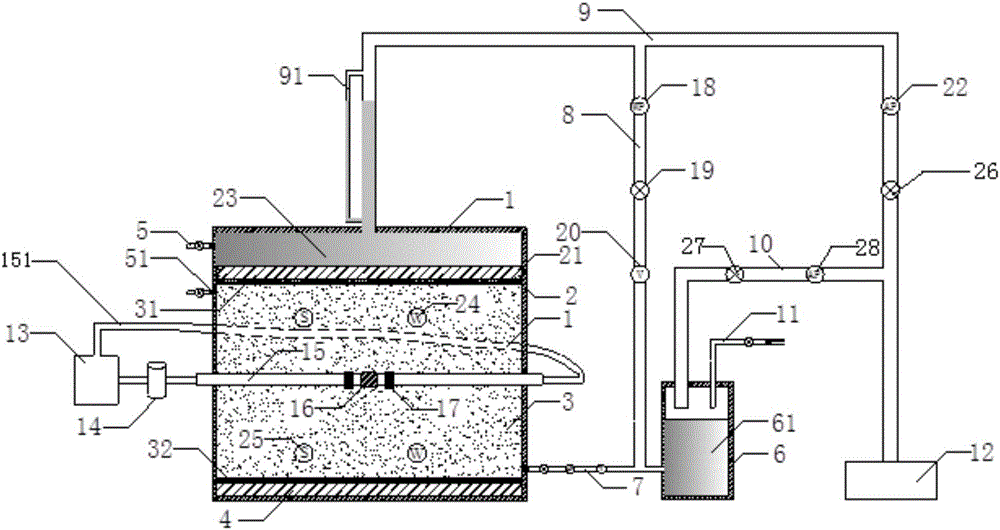

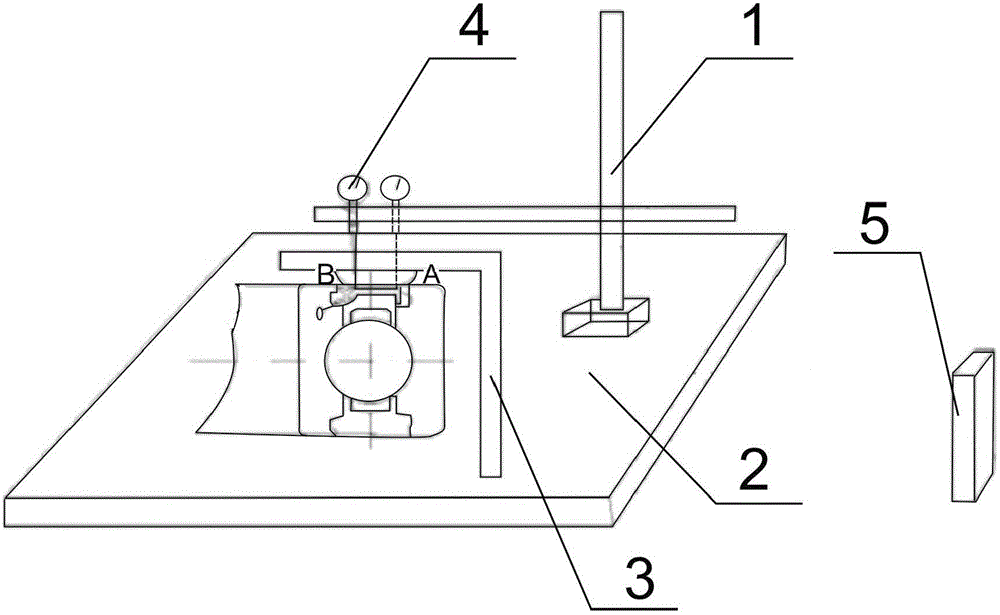

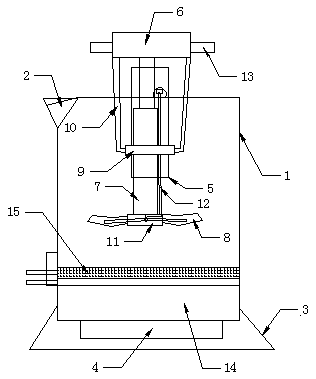

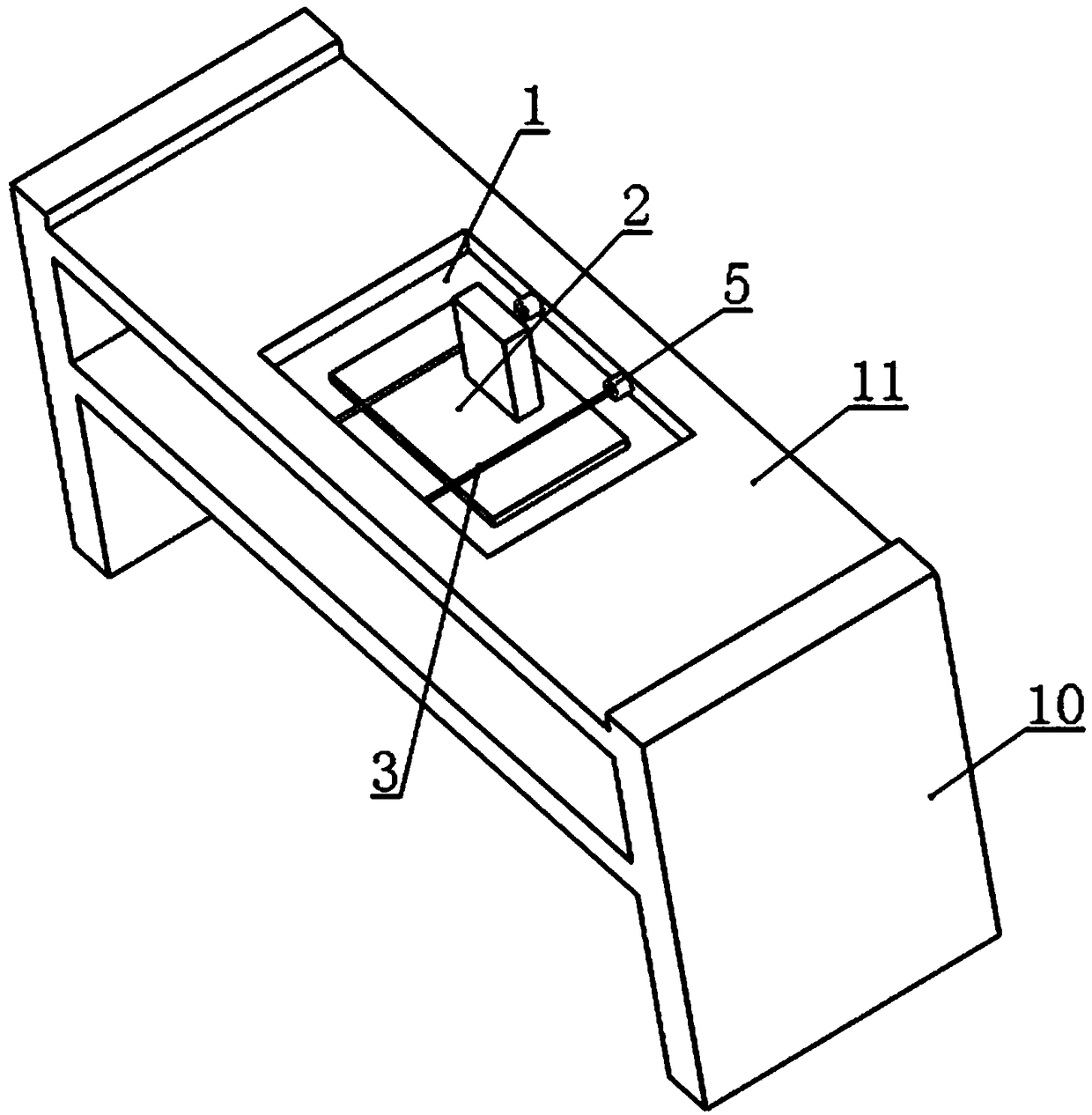

Test apparatus for simulating stratum uplift in grouting process and test method of test apparatus

InactiveCN106645582ASimple structureCompact structureMaterial analysisControl systemPore water pressure

The invention relates to a test apparatus for simulating stratum uplift in a grouting process and a test method of the test apparatus. The test apparatus comprises a test box, bearing plates arranged in the test box and dividing an inner cavity of the test box into a soil layer loading cavity and a pressurizing water cavity which are independent from each other, a water inlet control system and a high-pressure air adjusting system which are communicated with the pressurizing water cavity, a test soil layer arranged in the soil layer loading cavity, a grouting unit buried in the test soil layer and a grout control system connected with the grouting unit, wherein the soil layer loading cavity is communicated with the water inlet control system by virtue of a soil layer water inlet pipe, and a soil pressure gauge and a porous water pressure gauge are buried in the test soil layer. Compared with the prior art, the test apparatus is simple and compact in overall structure, economical and practical, applicable to the grouting simulation test under different filing conditions and different soil layer water content conditions, more convenient and rapider to assemble and operate, good in sealing effect, capable of accurately simulating the on-site grouting process and good in application prospect, and a grouting simulation effect is close the real situation.

Owner:中国人民解放军63926部队

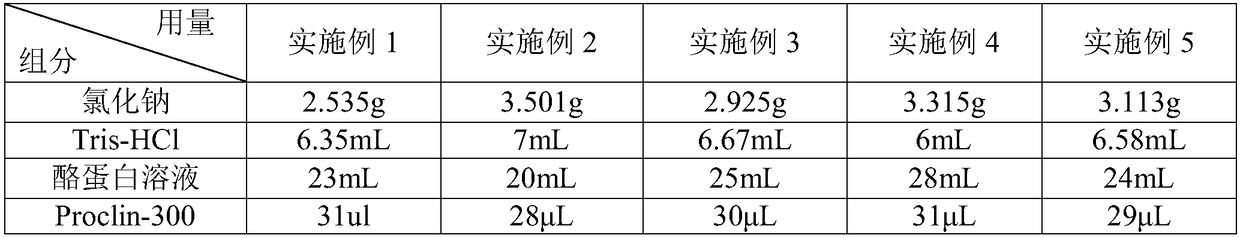

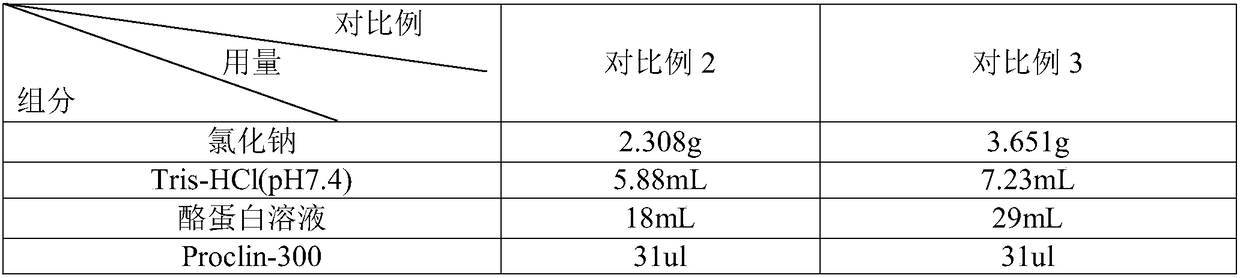

Protein preservation liquid, preparation method thereof, and method used for preservation of proteins using protein preservation liquid

InactiveCN108912205AImprove stabilityImprove protectionPeptide preparation methodsAntiseptic solutionsChloride sodium

The invention discloses a protein preservation liquid, a preparation method thereof, and a method used for preservation of proteins using the protein preservation liquid, and belongs to the technicalfield of protein preservation. 100mL of the protein preservation liquid comprises 2.535 to 3.501g of sodium chloride, 6 to 7mL of Tris-HCl buffer, 20 to 28mL of casein solution, 28 to 31<mu>L of an antiseptic, and the balance pure water. The pH value of the Tris-HCl buffer is 7.4 to 7.5. The protein preservation liquid is capable of avoiding a defect of convention preservation liquid that an extremely low temperature is needed for preservation, can be used for stable protein preservation, and is capable of obtaining relatively accurate protein preservation results.

Owner:杭州百殷生物科技有限公司

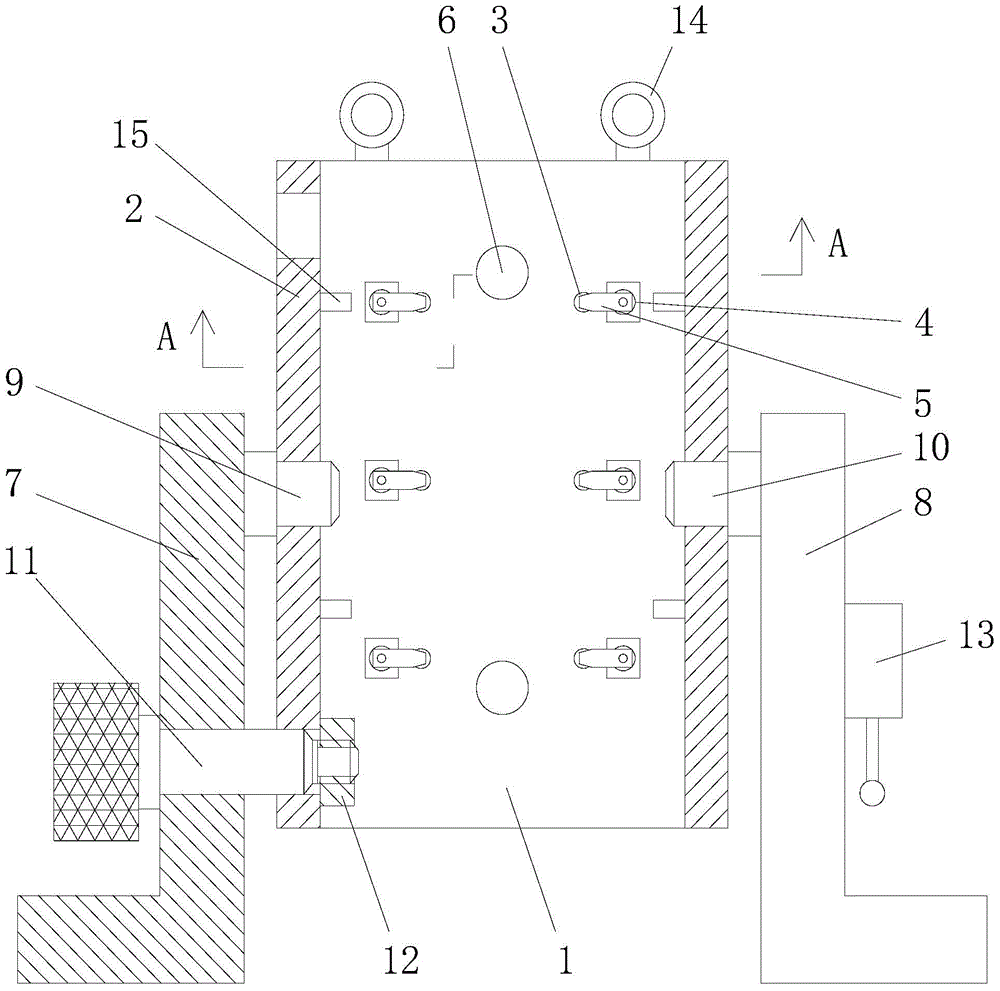

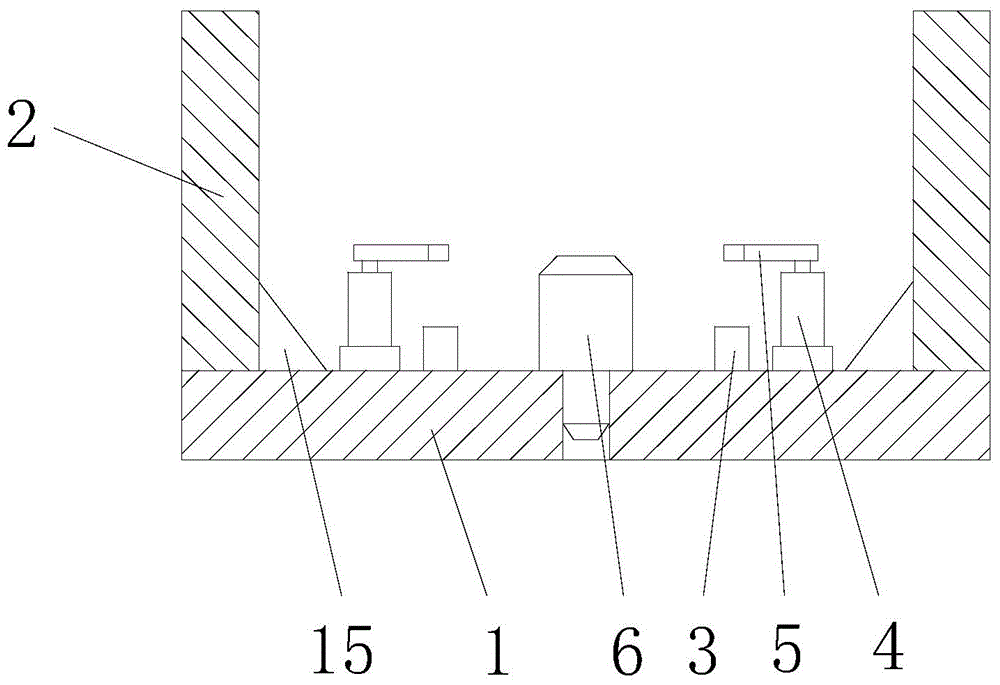

Rotary tooling for milling of end surface of engine cylinder

InactiveCN104551778AReduce processing timeIncrease productivityWork clamping meansPositioning apparatusEngineeringCylinder block

The invention discloses a rotary tooling for milling of an end surface of an engine cylinder. The rotary tooling comprises an U-shaped tooling body, a support column, an air cylinder, a workpiece press plate, a positioning pin, a left bracket, a right bracket, a left positioning pin, a right positioning pin and a bolt. The rotary tooling for milling of the end surface of the engine cylinder has the advantages that after one end surface of the engine cylinder is milled, a nut on the bolt is loosened, the bolt is taken out, the U-shaped tooling body is rotated by 180 degrees, then the bolt is inserted again, the nut is tightened, and the other end surface of the engine cylinder can be milled, so the processing time is greatly shortened, and the production efficiency is improved; the engine cylinder is positioned by the support column and the positioning pin, and the workpiece press plate is driven by the air cylinder to press and loosen the workpiece, so the clamping and loosening of the workpiece are convenient and rapid; the rigidity of the U-shaped tooling body is good, so the problem of stress vibration of the tooling during processing is solved, and the processing quality can be reliability guaranteed.

Owner:重庆秦安机电股份有限公司

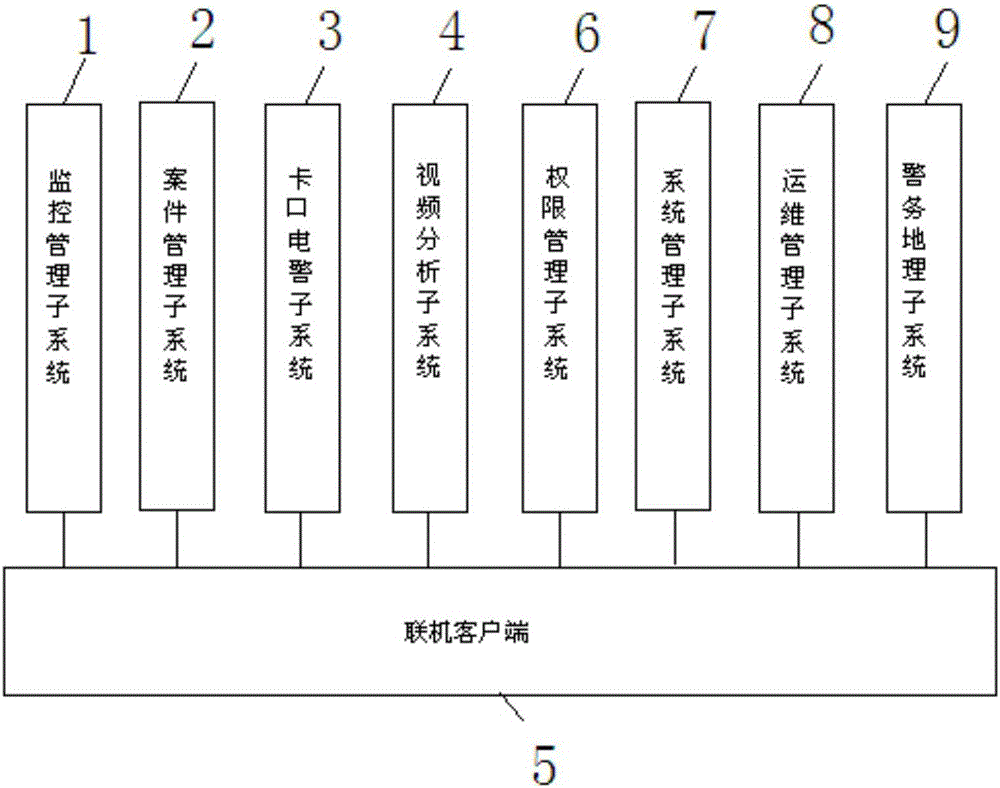

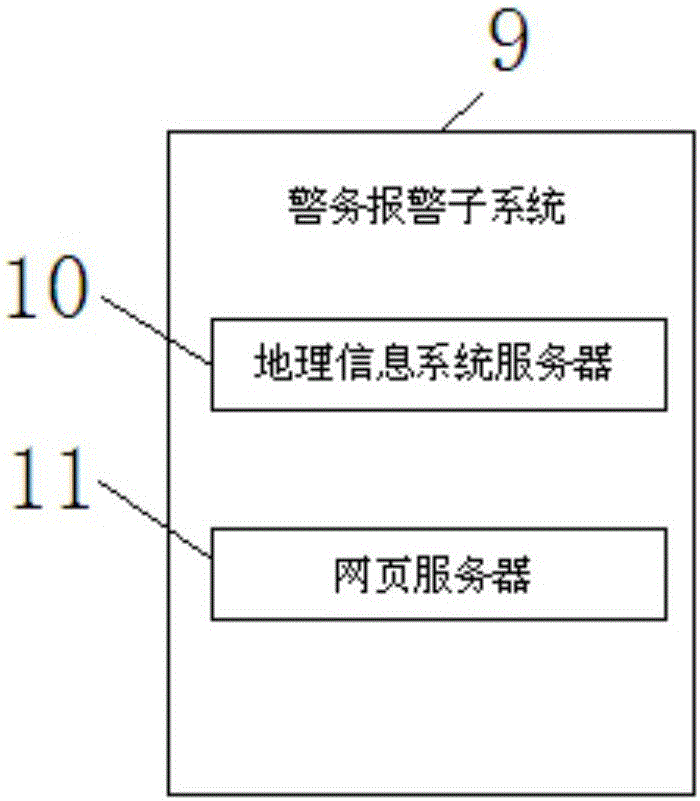

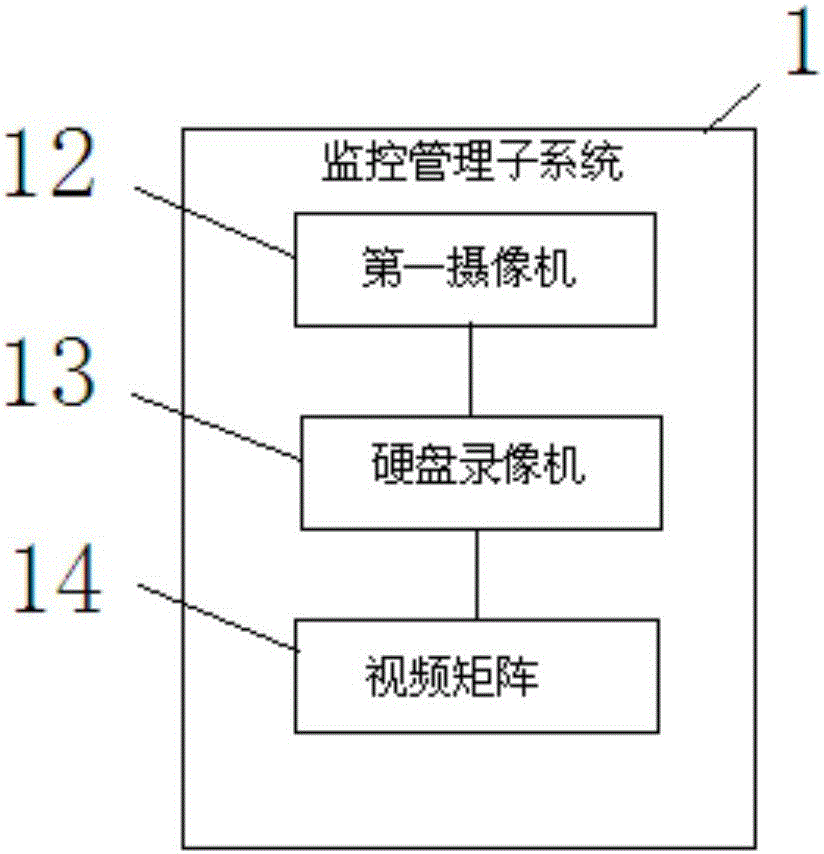

Geographic information technology-based comprehensive management platform

InactiveCN106548626ARealize unified managementImplement schedulingDetection of traffic movementVideo monitoringCheck point

The invention discloses a geographic information technology-based comprehensive management platform and belongs to the technical field of road traffic management. The comprehensive management platform comprises a plurality of subsystems listed as follows: a monitoring management subsystem, a case management subsystem and a check point electronic police subsystem, wherein the monitoring management subsystem is connected with video monitoring devices and is used for realizing remote controlling and monitoring as well as unified management of the video monitoring devices; the case management subsystem is used for extracting and saving relevant information of law violating vehicles, the check point electronic police subsystem is connected with a high definition check point device and an electronic police device, and the check point electronic police subsystem is also used for check point real time monitoring and electronic police real time monitoring. The beneficial effects of the geographic information technology-based comprehensive management platform are that all resources of an intelligent traffic system are highly integrated, unified management and scheduling of road traffic are realized, strong system functions are fulfilled, relevant information of the law violating vehicles can be timely and accurately detected and uploaded, alarm over vehicles having law violation records can be sent out, and various requirements of road traffic management can be met.

Owner:INESA ELECTRON

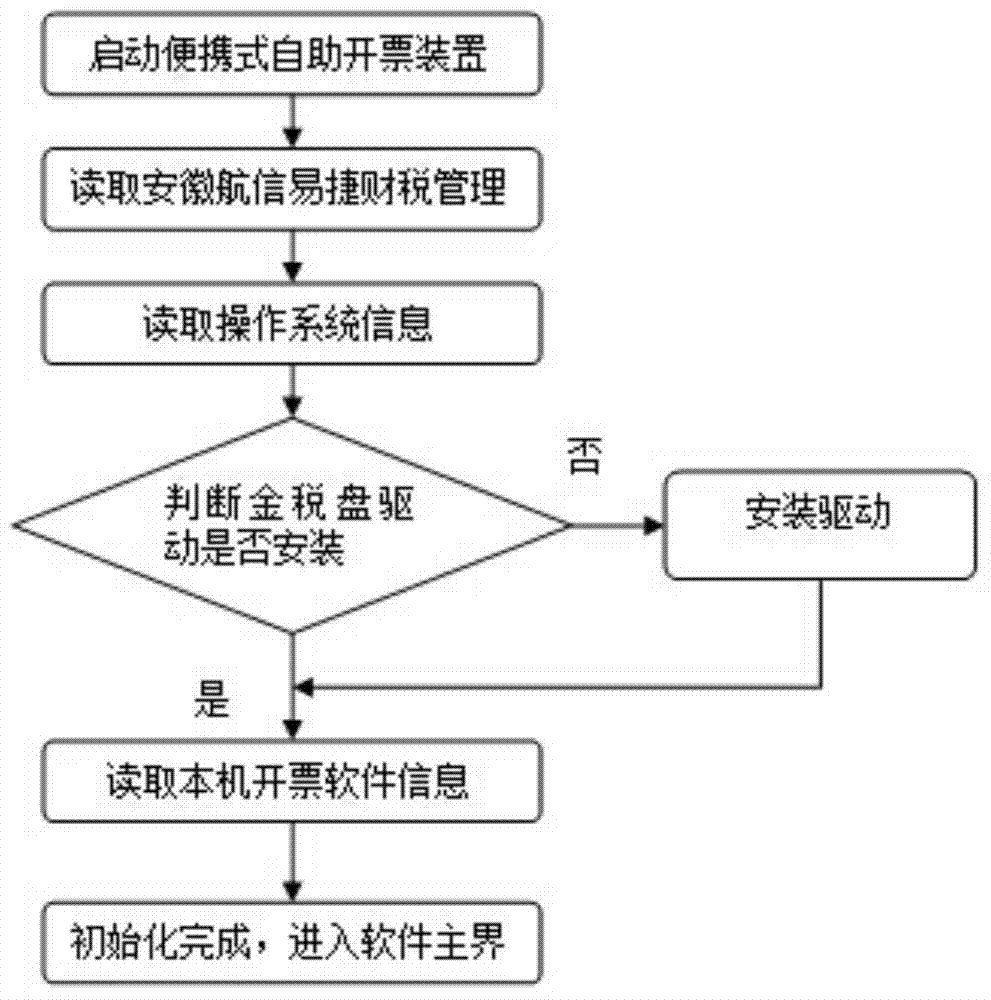

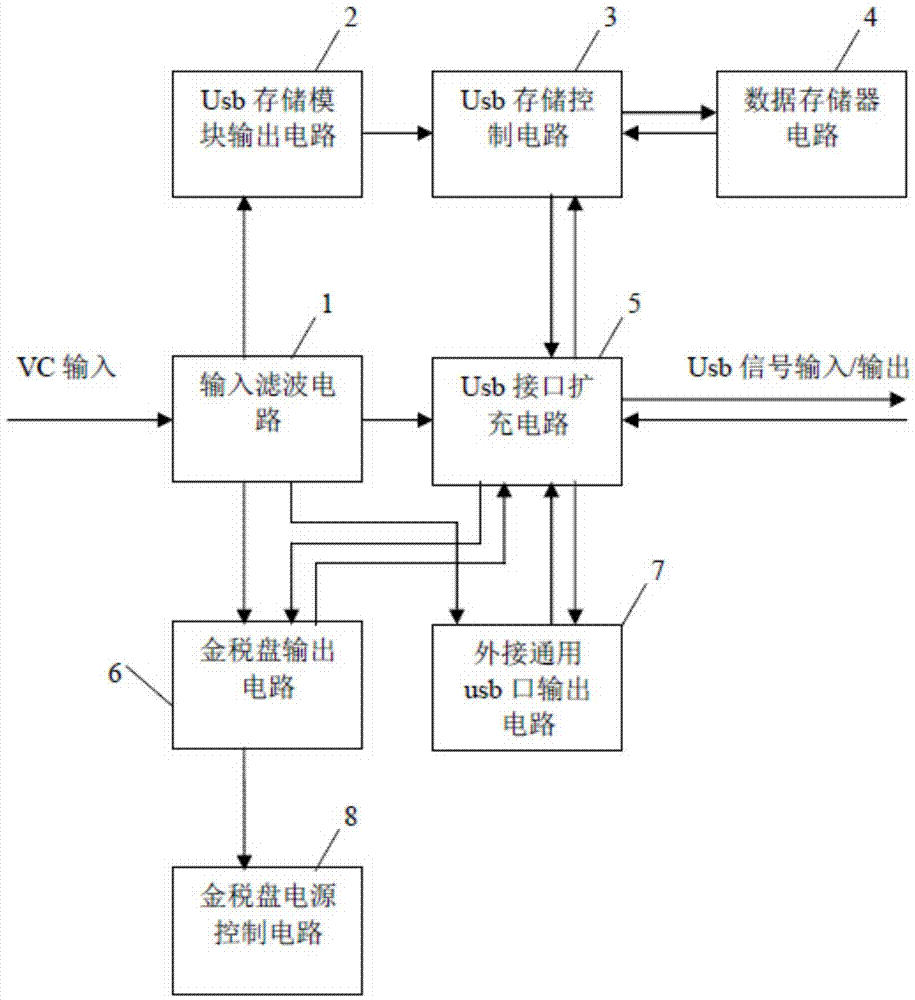

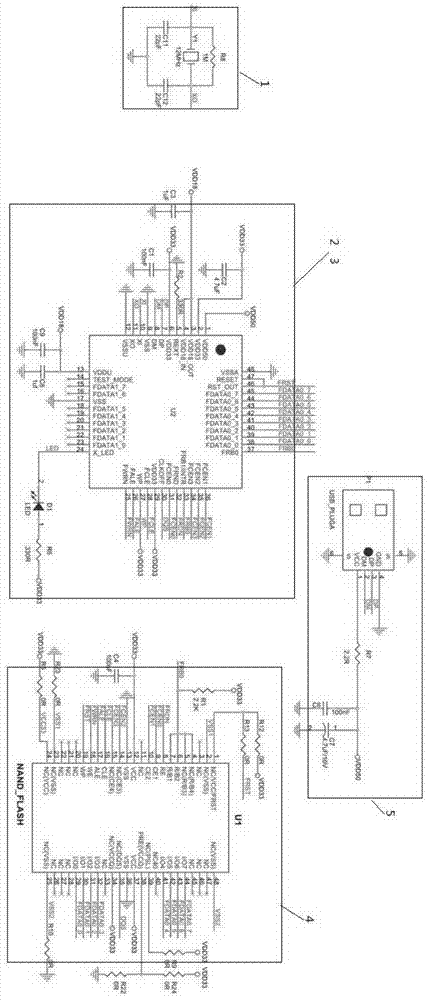

Control method of portable self-service billing system

InactiveCN104503926AControl method implementationEasy to installCash registersElectric digital data processingOperational systemInvoice

The invention discloses a control method of a portable self-service billing system. The control method comprises the steps of inserting a portable self-service billing device into a user terminal equipped with a USB interface by a user as the requirement; starting the portable self-service billing device; to automatically read Anhui Hangxin Yijiejie fiscal and taxation management system through a user terminal interface unit. The portable self-service billing device can be used for automatically reading the information of an operation system of the user terminal. The control method of the portable self-service billing system, by being compared with the prior art, has the advantages that the portable self-service billing device can be used as being inserted, and anti-counterfeiting billing system data can be automatically synchronized to the Anhui Hangxin Yijiejie fiscal and taxation management system; the data of a bill database can be automatically backed up to the computer and a safety area; all backup data can be quickly recovered as requirement.

Owner:安徽航天信息有限公司

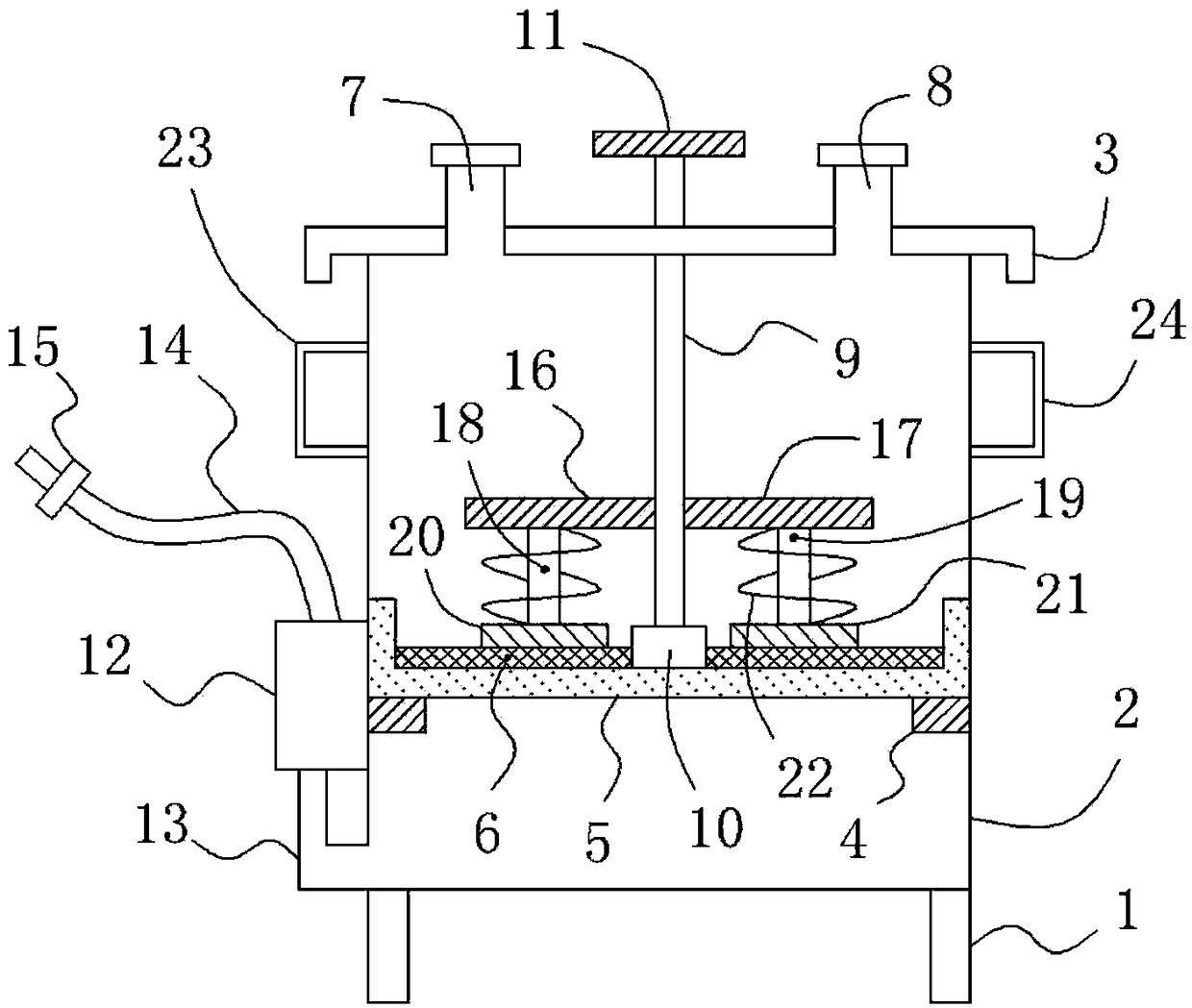

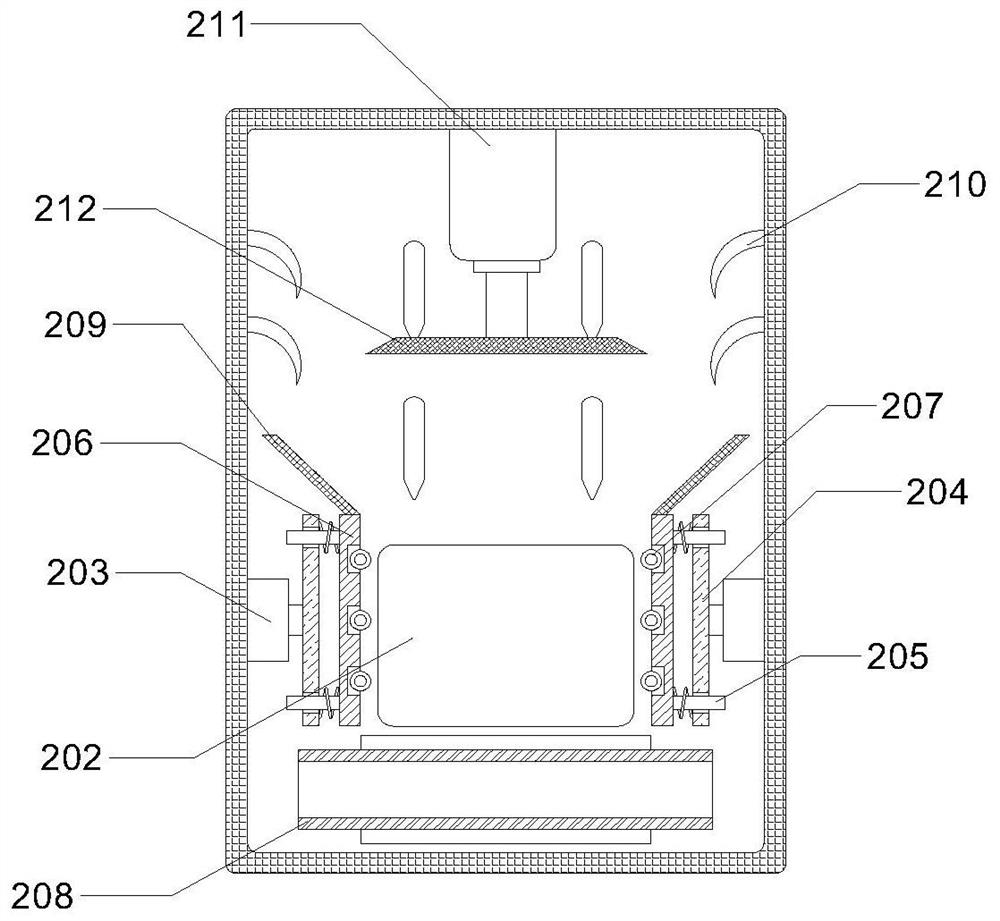

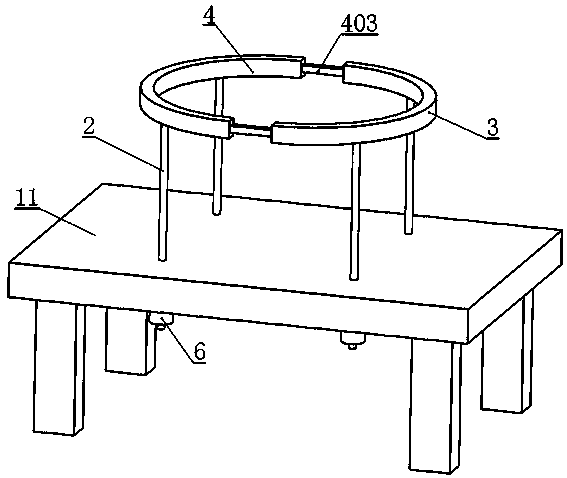

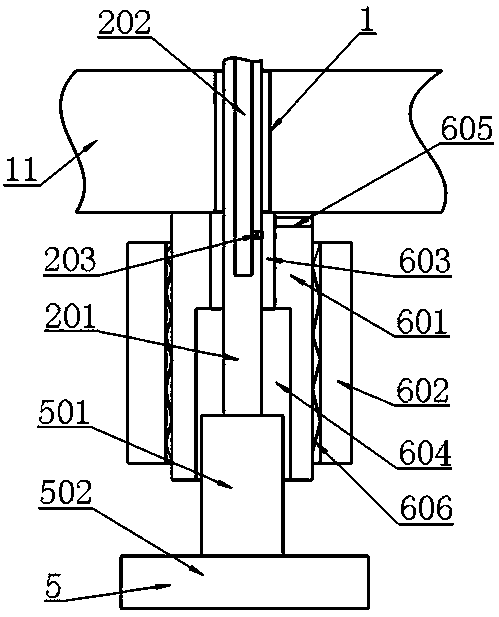

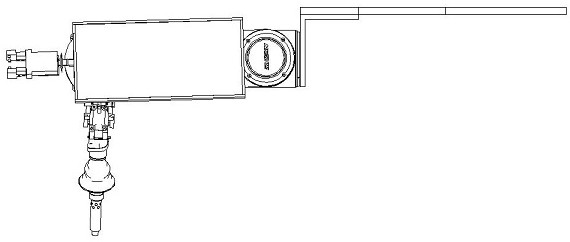

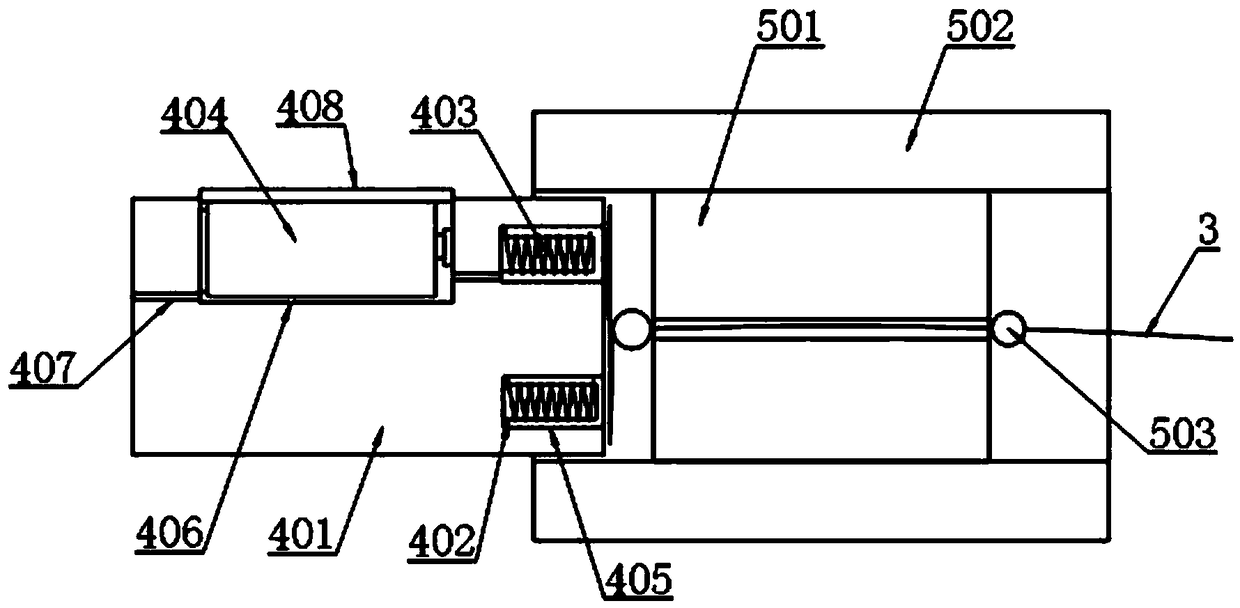

Environmental engineering atomizing device

InactiveCN108607751AAvoid cloggingConvenient and quick operabilityLiquid spraying apparatusFiltrationCoil spring

The invention relates to an environmental engineering atomizing device. The environmental engineering atomizing device comprises a support, a liquid storage barrel and a barrel cover, wherein the interior of the liquid storage barrel is connected to a fixed ring; a filtration barrel is put on the fixed ring; a bottom wall through hole is formed in the bottom wall of the filtration barrel, and thebottom wall of the filtration barrel is covered by a filtering mesh; a rotary rod is arranged above the filtration barrel and is rotatably connected to the bottom wall of the filtration barrel by a bearing; the top end of the rotary rod penetrates through a rotary rod through hole upwards and is provided with an upper handle; a pump body and a storage battery are arranged at the left side of the exterior of the liquid storage barrel, and a water outlet is formed at the bottom of the left side and is connected to a water inlet of the pump body through a water outlet pipe; a water outlet of thepump body is connected to a water spraying hose and an atomizing head; the rotary rod is connected to a left stirring rod and a right stirring rod which are connected to a left telescopic link and a right telescopic link; the bottoms of the left telescopic link and the right telescopic link are connected to a left brushing rod and a right brushing rod; and spiral springs are arranged on the exteriors of the left telescopic link and the right telescopic link in a sleeving manner. Due to the adoption of the structure, the environmental engineering atomizing device is convenient and fast to use,and the blocking of the atomizing head can also be effectively avoided in a working process.

Owner:天津市西海环境工程设计有限公司

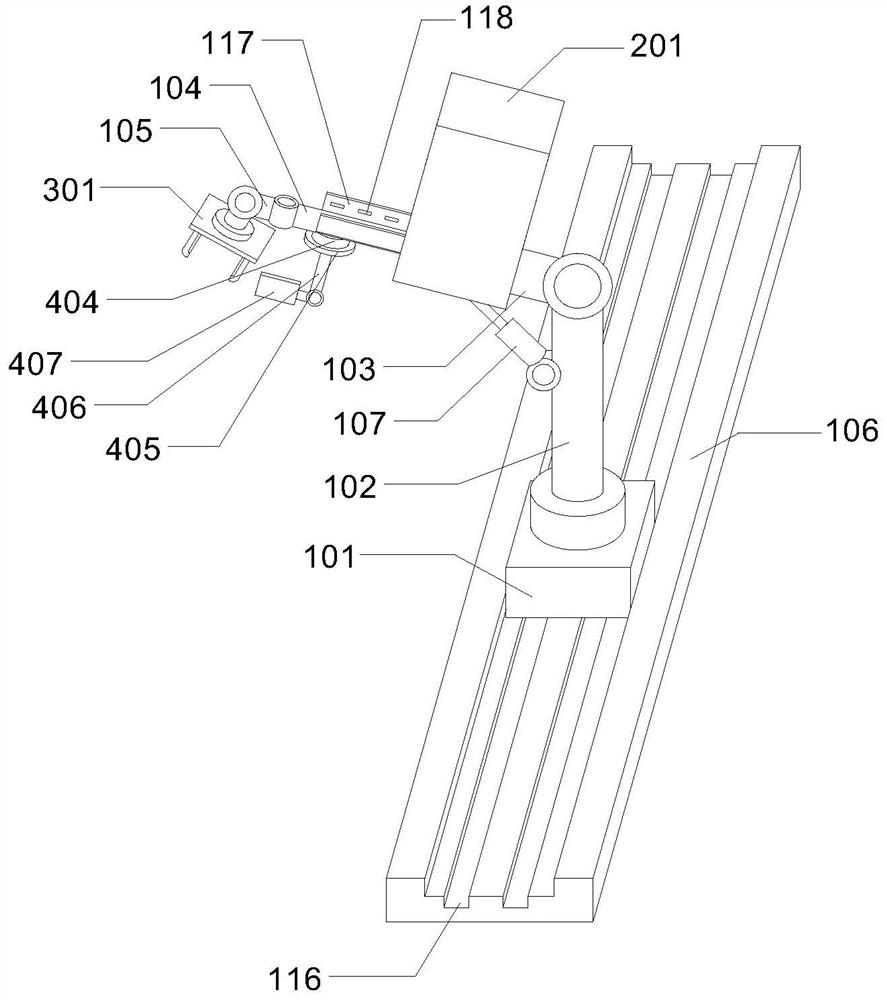

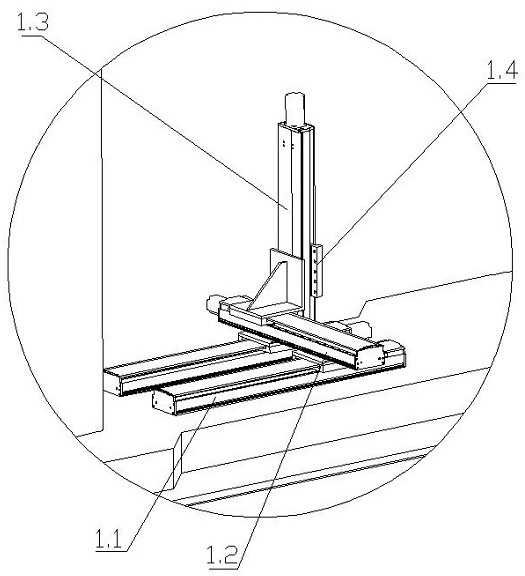

Movable seven-degree-of-freedom carrying mechanical arm

ActiveCN112571399AConvenient and quick storageConvenient and quick operabilityManipulatorRobotic armStructural engineering

Owner:安徽橡树工业设计有限公司

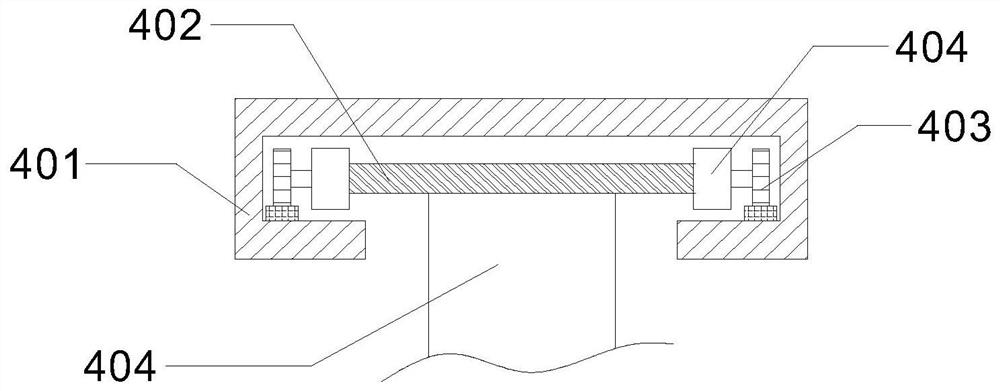

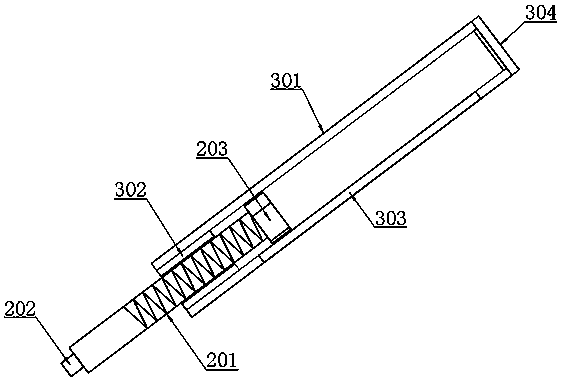

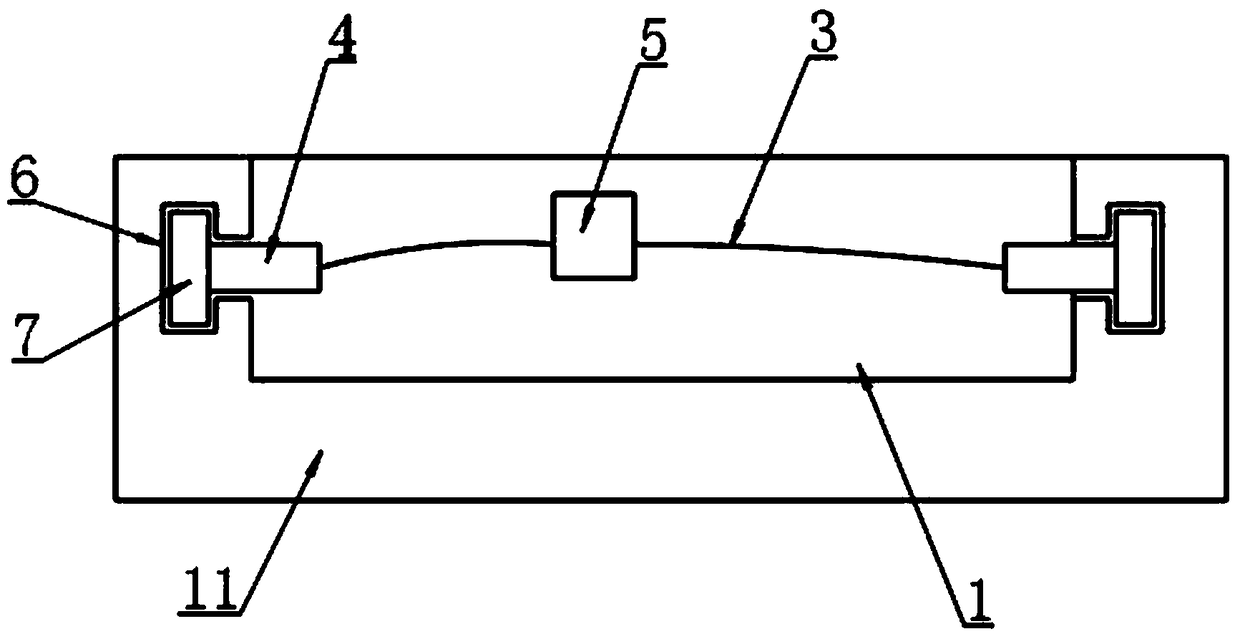

Screw rod for high-safety chair ascending and descending

PendingCN110074576ALifting effect is goodPrevent rotation and fallRod connectionsAdjustable chairsEngineeringMechanical engineering

The invention belongs to the technical field of a screw rod structure, in particular to a screw rod for high-safety chair ascending and descending. The effect of preventing the screw rod for ascendingand descending from rotating and falling down is achieved in a mode of installing a screw rod main body unit, an inner sleeve tube unit and an insertion connection post unit on the outer sleeve tubeunit. The screw rod has the advantages that a screw rod clamping falling-prevention structure is reasonable and effective; the clamping state building and relieving operation is convenient and fast; the screw connection integral ascending and descending use effect is good; the accidental rotating falling cannot easily occur.

Owner:淳安青节电子商务有限公司

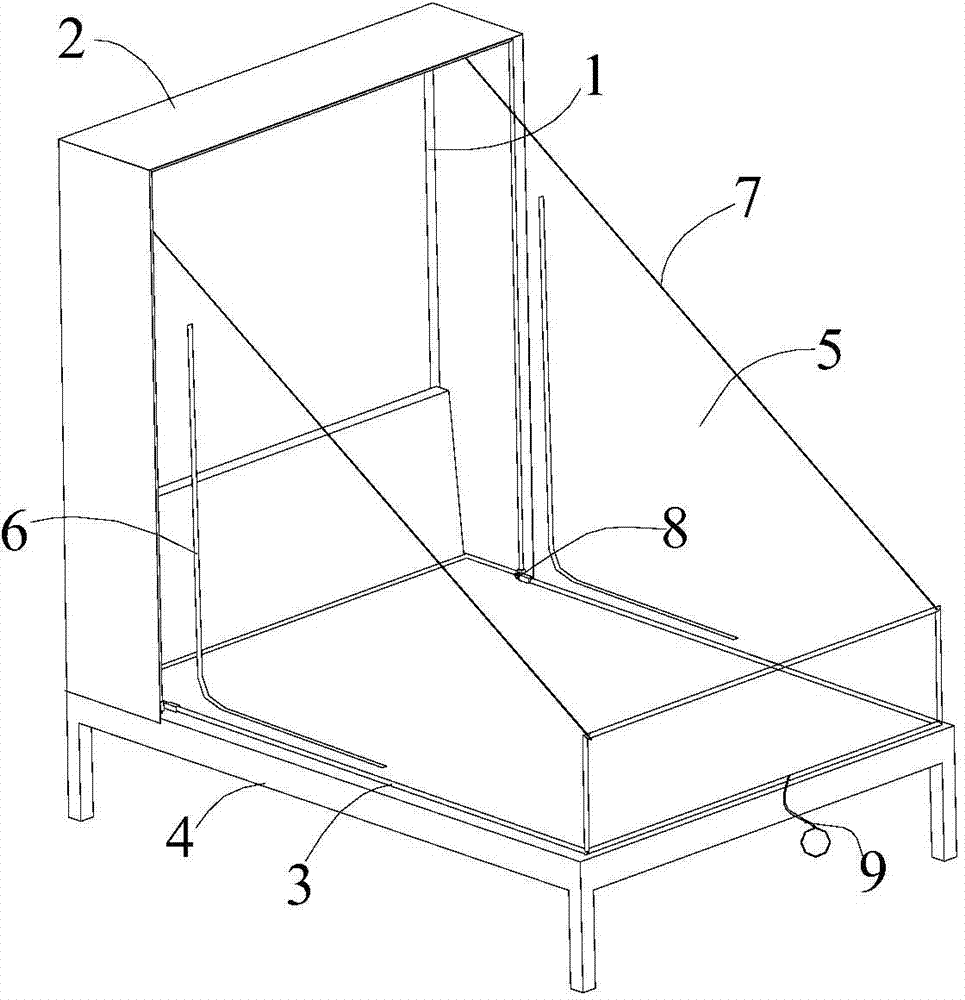

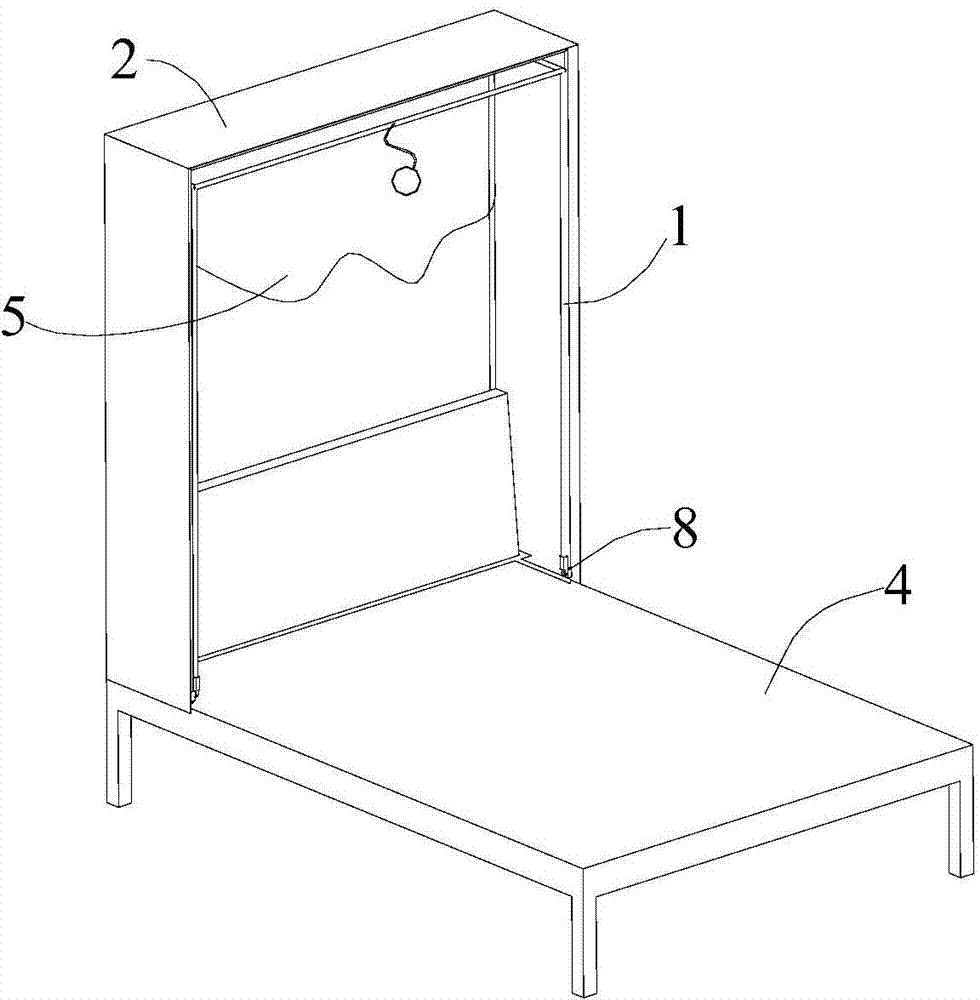

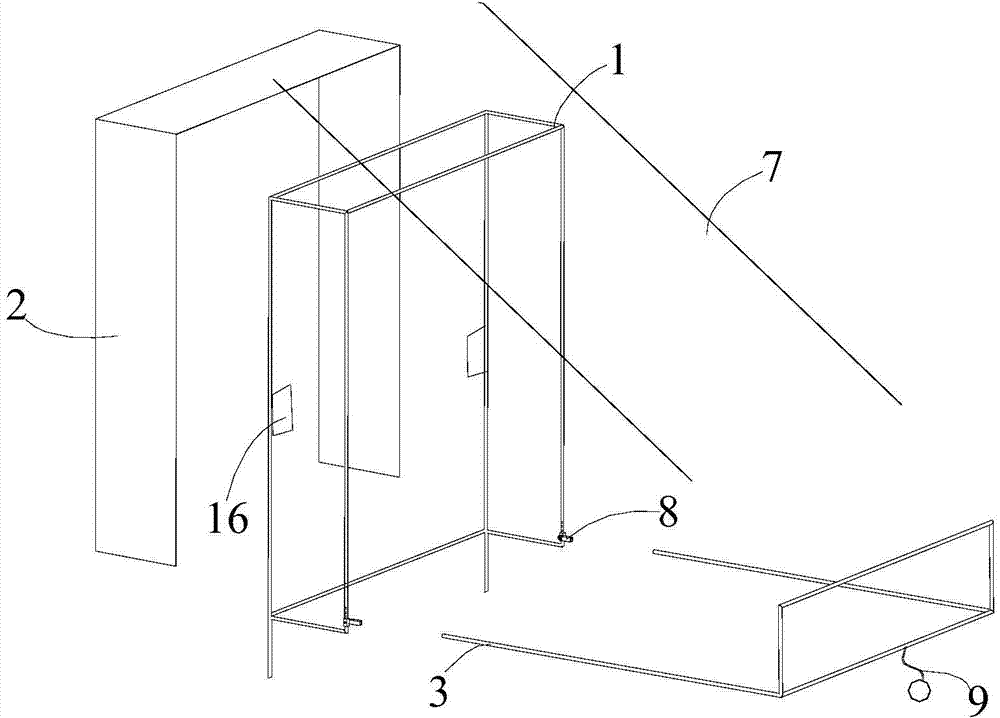

Inclined foldable mosquito net

The invention discloses an inclined foldable mosquito net. The inclined foldable mosquito net comprises a fixed support vertically fixed to one side of a bed body, a first movable support of which one end is hinged to the fixed support, and a first mosquito net sleeving between the fixed support and the first movable support, wherein the top surface of the first mosquito net adopts a planar inclined structure which is inclined to one unfolding side of the first movable support. When the inclined foldable mosquito net is in use, the first movable support drives the first mosquito net fixed to the first movable support to rotate around a hinged seat of the fixed support to be unfolded and flatly placed and perpendicular to the fixed support. When the inclined foldable mosquito net is not in use, the first movable support drives the first mosquito net fixed to the first movable support to rotate around the hinged seat of the fixed support to be vertical and then folded into the fixed support. According to the inclined foldable mosquito net, the automatic folding function can be realized through only the fixed support and one group of movable supports, as well as a contractile stay cord device, the use is as convenient and quick as the folding operation, folding can be realized freely, and the full-automatic or remote-controlled folding function of the mosquito net can be achieved in the mode that a micro motor drives a stay cord.

Owner:王行军

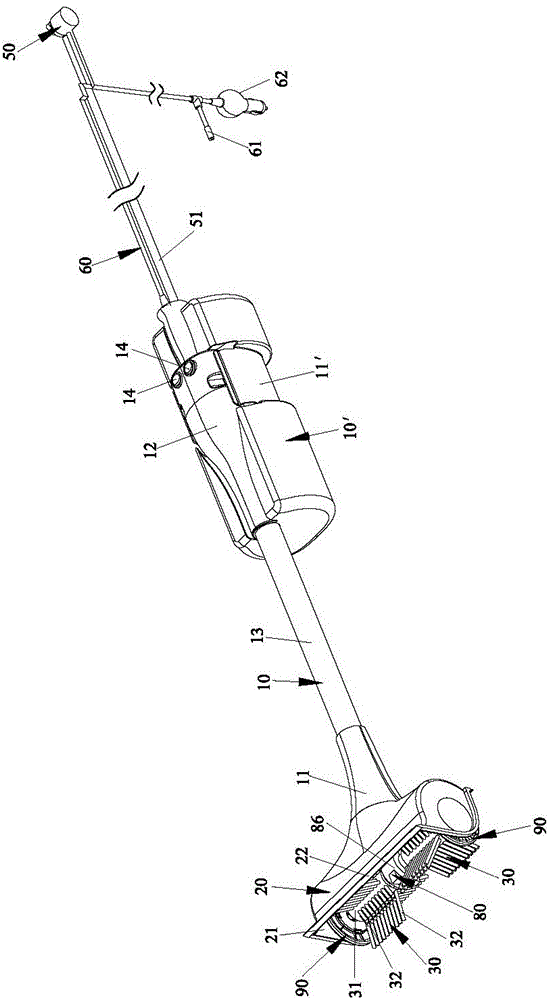

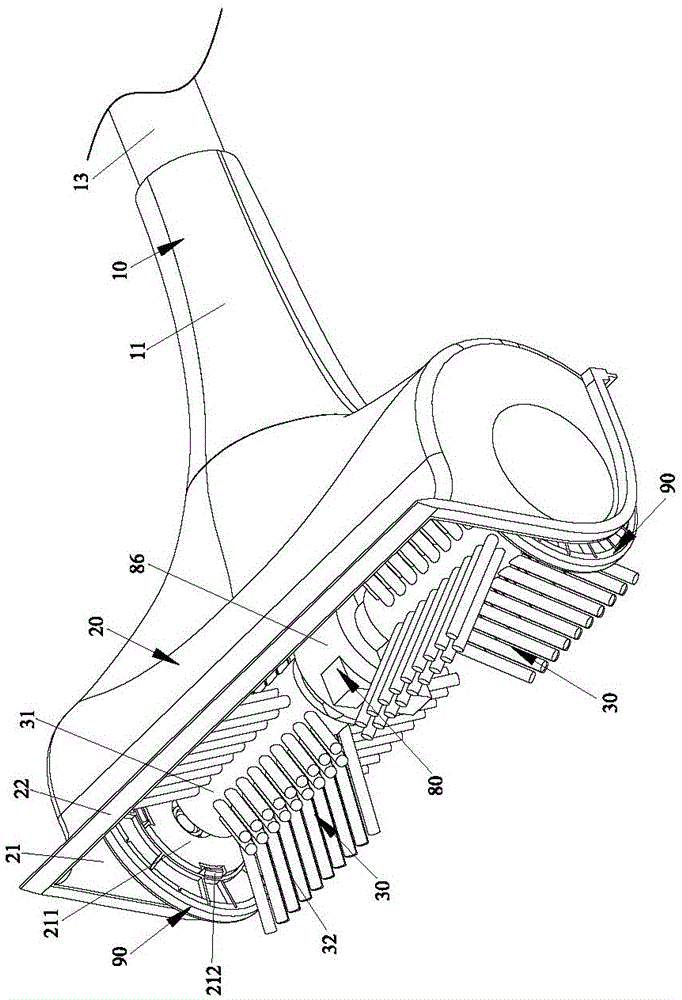

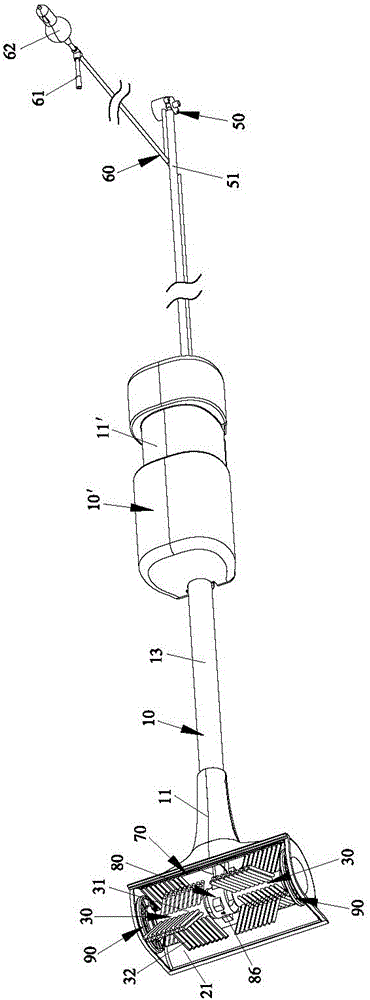

Bionic mini car washer

ActiveCN105083231AAvoid harmAvoid repeated washingCleaning apparatus for vehicle exteriorsCleaning using toolsMotor driveHand held

The invention discloses a bionic mini car washer which comprises a handle, a shell, brush rollers, a motor, a water pump and a power wire. The shell is arranged at the front end of the handle and provided with a concave cavity, the side edge of an opening of the concave cavity is provided with a water box, and multiple water outlets which are distributed at intervals are formed in the water box; the brush rollers are arranged in the concave cavity and exposed out of the shell, and the water outlets are right opposite to the brush rollers; the motor is arranged in the back end of the handle, the motor drives the brush rollers to rotate through a transmission mechanism, the water pump is communicated with the interior of the water box through a pipeline, and the power wire is connected with the motor and the water pump. Thereby, the motor and the transmission mechanism are matched to drive the brush rollers to rotate, water is pumped into the water box by the water pump to spray the brush rollers wet, the brush rollers stained with the water are utilized to simulate the licking action of animals to wash and brush a car body, and therefore the harm to the car body can be effectively avoided; the bionic mini car washer is in a handheld type, operation and usage are both very convenient and fast, the water usage amount is small, the advantages of energy conservation, water conservation, environmental protection and the like are achieved, and the bionic mini car washer is very suitable for household use.

Owner:东莞市宏元电子科技有限公司

Rice flour preparation device

PendingCN107348342AHigh degree of automationImprove toughnessFood shapingEngineeringElectromagnetic heating

The invention discloses a rice flour preparation device which is characterized in that a heating device is composed of a heating cylinder, an electromagnetic heating coil and an insulation cover; a heat storage cavity which surrounds a material extrusion channel and is filled with heat conduction oil is arranged in the heating cylinder; the insulation cover is arranged at the periphery of the heating cylinder, and the electromagnetic heating coil is arranged in a heating cavity formed between the insulation cover and the heating cylinder; a spiral material extrusion rod extends into the material extrusion channel from the right side of the heating cylinder; and a rice flour forming assembly is arranged at the left end of the heating cylinder and is communicated with the material extrusion channel. The rice flour preparation device has the advantages of compact and scientific structure, safe and reliable work, long service life, short production cycle and high degree of automation, and the produced rice flour is safe and guaranteed; the rice flour preparation device has the characteristics of small volume, small production site occupation area, energy saving and environmental protection, and is convenient and fast to maintain, very convenient to assemble, disassemble and clean and convenient to operate; and furthermore, the processed rice flour is high in degree of curing, the vermicelli is fine and uniform, has good toughness, is not easy to break, is smooth and delicate and has good taste, and the produced flour is not sticky.

Owner:广东名得科技有限公司

Fast blocking device of pipe opening

The invention provides a fast blocking device of a pipe opening, which is applicable to the technical field of controllable no-well-killing operation. The fast blocking device comprises a shell, wherein one end of the shell is provided with a slip containing cavity, and a pushing mechanism cavity is formed at the other end of the shell; a sliding block can be movably arranged in the pushing mechanism cavity; the two ends of a spring push against the shell and the sliding block respectively; one end of the sliding block is connected with a central pipe, one end of the central pipe is protruded from the shell and forms a sealing part which can be in sealing connection with the inner wall of a blocked pipe column; the end part of the pushing mechanism cavity is connected with a handle which can push the sliding block and drive the central pipe to move axially; the slip containing cavity is provided with a plurality of slips along the peripheral direction; the slips can extend outwards to be protruded along the radial direction of the slip containing cavity to be fastened with the inner wall of the pipe column. The fast blocking device provided by the invention has the advantages that the structure is simple and compact, the installation and the maintenance are convenient and fast; fast blocking to the pipe opening can be realized, and an overflowing device is also arranged, so that the safe and environmental-friendly effects are achieved.

Owner:PETROCHINA CO LTD

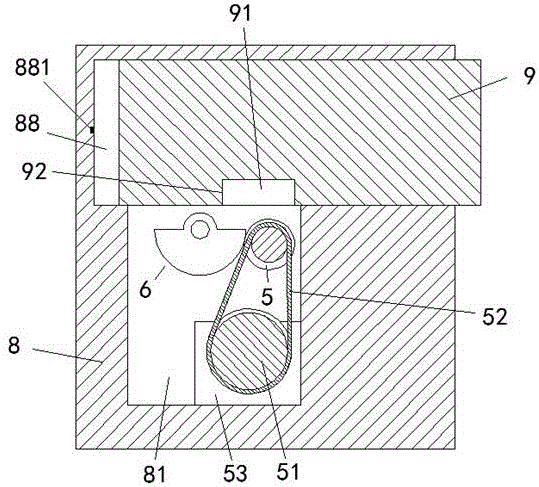

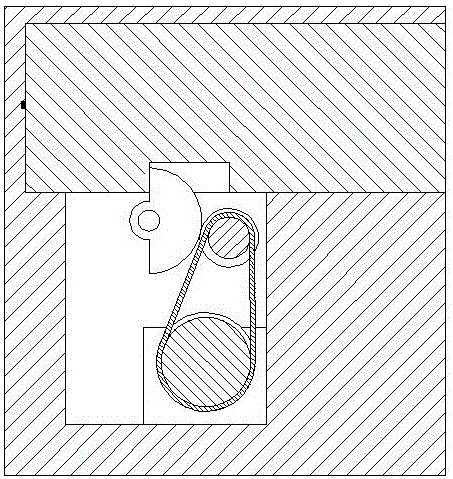

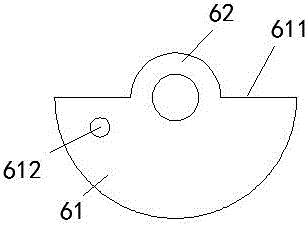

Locking device for logistics packing box

The invention relates to a locking device for a logistics packing box for locking a logistics packing box (9) which is stored. The device comprises a packing box loading rack (8) and a packing box storage cabin (88) which is arranged in the packing box loading rack (8) and is used for storing the logistics packing box (9), wherein a locking mounting hollow cabin (81) communicated with the packing box storage cabin (88) is arranged below the packing box storage cabin (88) in the packing box loading rack (8), a locking operating assembly is mounted in the locking mounting hollow cabin (81), and the locking operating assembly comprises a moon-shaped tooth part (6); the moon-shaped tooth part (6) comprises a semicircle part (61) and a locking round part (62) which is fixedly connected to the middle part of the plane end of the semicircle part (61).

Owner:刘孟香

Device and method for measuring sealing state of bearing

InactiveCN103148987ASmall temperature changeImprove sealingAngles/taper measurementsFluid-tightness measurementEngineeringMechanical engineering

Owner:GUIZHOU HONGZHI PRECISION BEARING

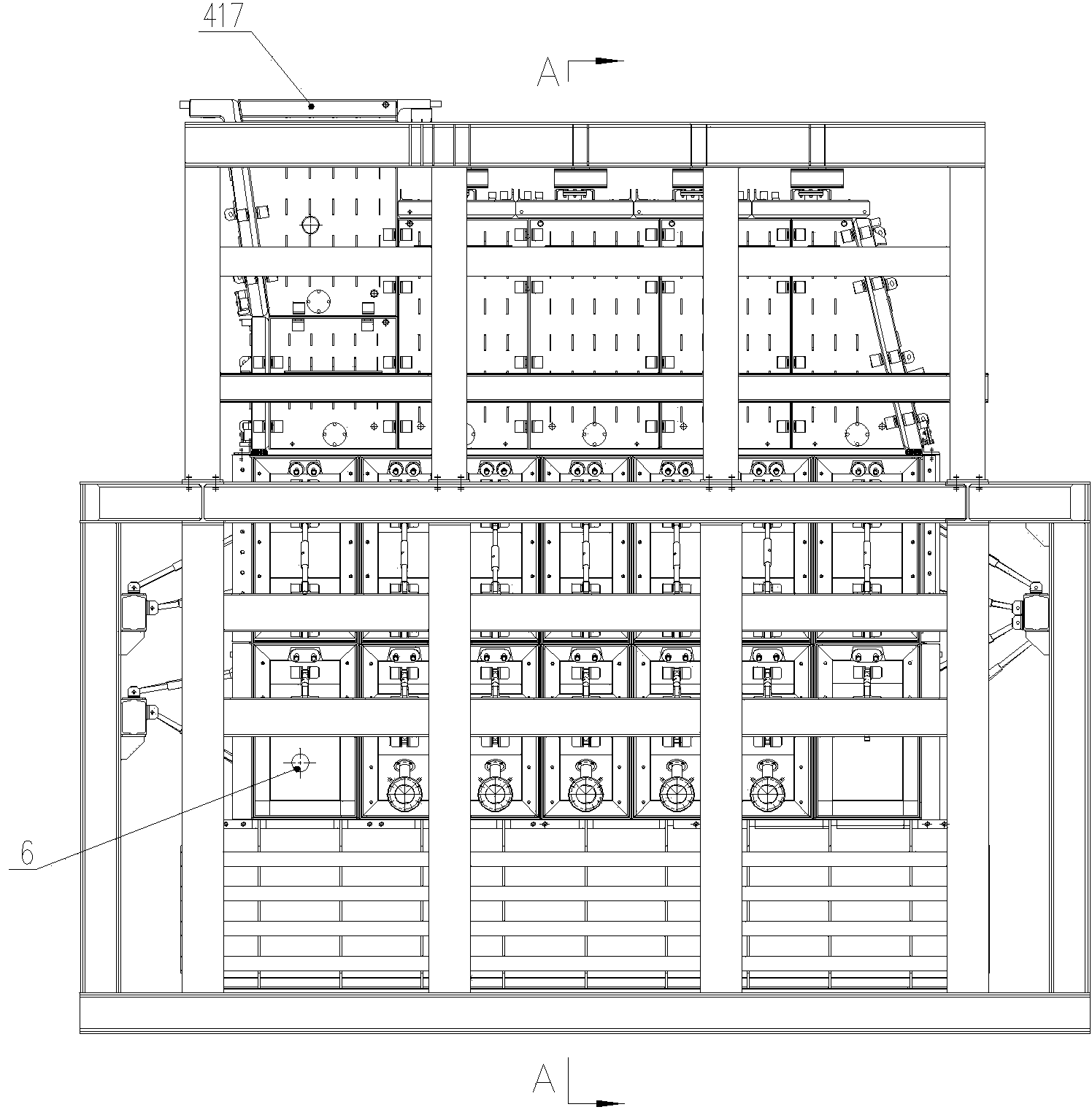

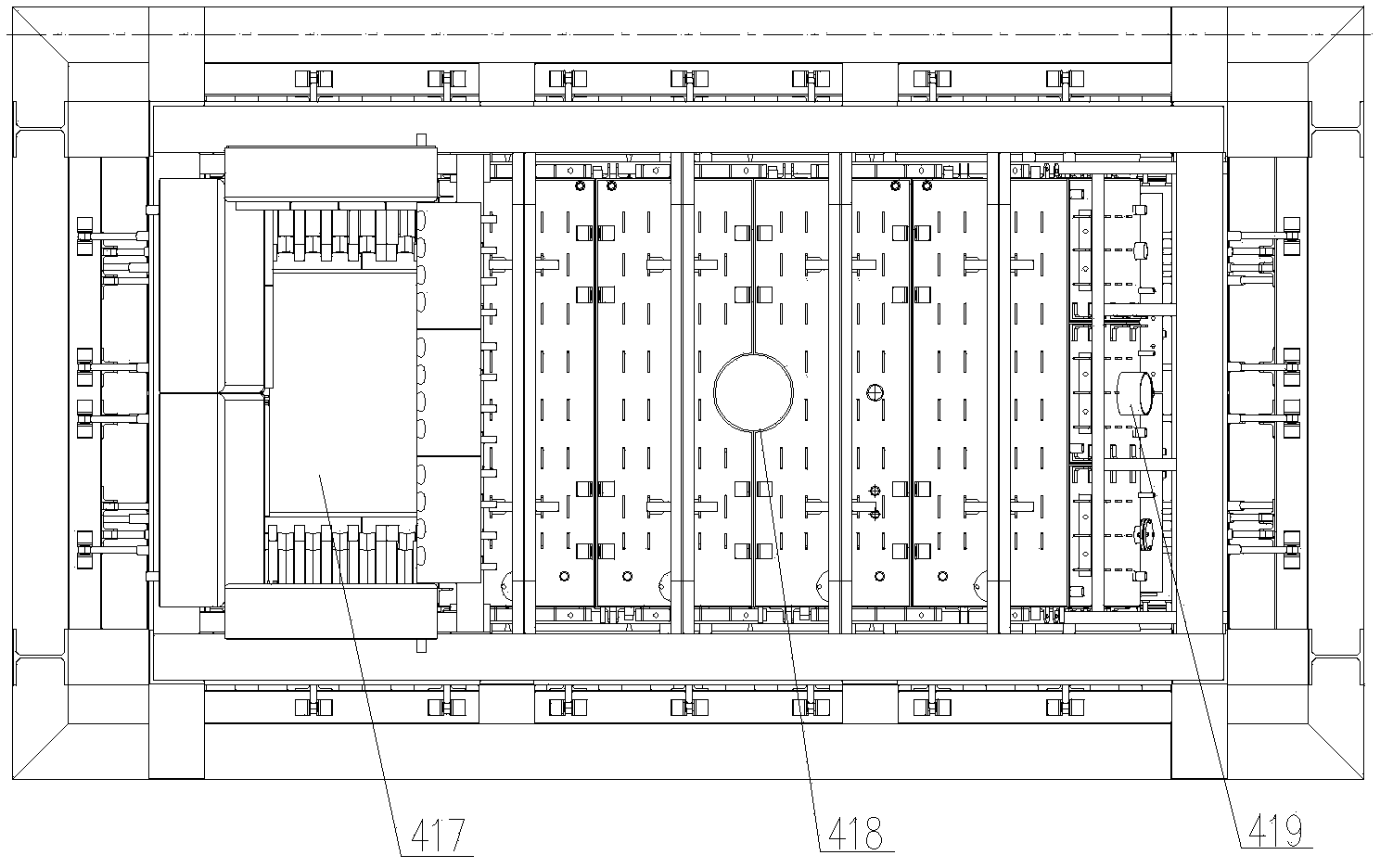

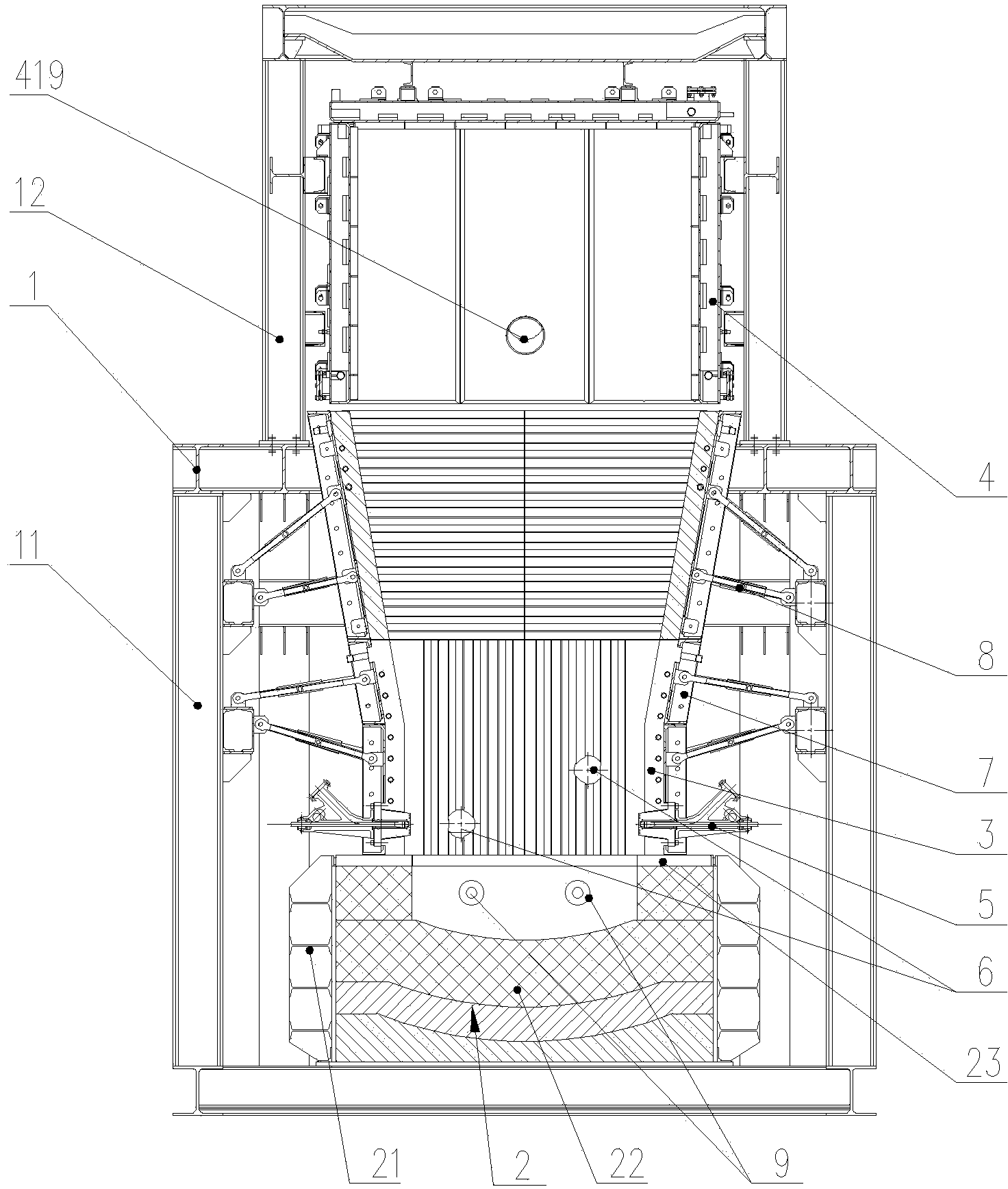

Oxygen-enriched smelting furnace for treating low-grade multi-metal material

InactiveCN103451430AQuick installationConvenient and quick operabilityRotary drum furnacesCrucible furnacesMelting tankSlag

The invention discloses an oxygen-enriched smelting furnace for treating a low-grade multi-metal material. The oxygen-enriched smelting furnace comprises a furnace hearth, a copper water jacket furnace wall and a hanging-type steel water jacket which are sequentially arranged from bottom to top, wherein a steel structural frame is arranged on the peripheries of the furnace hearth, the copper water jacket furnace wall and the hanging-type steel water jacket, the furnace hearth is positioned on a skeleton of the bottom surface of the steel structural frame, a fixed frame for connecting with the steel structural frame is arranged on the outer wall of the copper water jacket furnace wall, and the hanging-type steel water jacket is hung at the upper end of the steel structural frame; the copper water jacket furnace wall comprises a plurality of layers of copper water jackets, and the bottom of the copper water jacket at the bottommost layer is provided with an oxygen spray nozzle and a punching slagging device; the upper end of the hanging-type steel water jacket is provided with a flue hole and a charging hole which are communicated with the hanging-type steel water jacket and used for discharging smoke and charging. The left and right deformation of the water jacket is avoided due to the structure of the hanging-type steel water jacket, the defects that a slag hole water jacket is prone to leak, and the furnace shutdown is needed during the replacement of the water jacket are overcome due to the structure of the punching slagging device, and the safety using property of the oxygen-enriched smelting furnace is improved. The oxygen-enriched smelting furnace has the characteristics that during smelting, the amount of flue gas is small, little heat is taken away by flue gas, the temperature of a molten pool is high, and lead and zinc are easy to volatile.

Owner:CINF ENG CO LTD

Spray collecting device

PendingCN109060422ASimple structureAvoid external interferenceWithdrawing sample devicesEngineeringElectromagnet

The invention provides a spray collecting device. The spray collecting device comprises a collecting chassis, a collector, a cover plate, a pull rod, a lever, a lever rotating shaft, a waterproof boxmounting plate, a waterproof box, an electromagnet and a connection pin. The collecting chassis is a square box body; the collector is installed in the collecting chassis and can be taken out form oneside of the collecting chassis; and the cover plate is installed in a clamping groove of the collecting chassis, is positioned at the upper portion of the collector, is attached to the collector, andcan slide back and forth. The spray collecting device can avoid external interference in the collecting process, the problem that abnormally distributed liquid continues to flow into a liquid trap todisturb normal collection after a nozzle is opened and closed, the whole spray device is simple in structure, an experimental device is convenient to operate and adjust, manufacturing and maintenancecosts are low, the stability is good, the reliability is high, and the engineering application is facilitated.

Owner:JIANGSU UNIV OF SCI & TECH

Vegetable and fruit exhibition stand for agricultural picking tour

ActiveCN109363446AEffectively fixedEffective exhibitionShow shelvesShow hangersAgricultural engineeringElectromagnet

The invention belongs to the technical field of agriculture, and particularly relates to a vegetable and fruit exhibition stand for an agricultural picking tour. By arranging a wire hole, a connectingwire, a fixing semicircular unit, a plugging semicircular unit, a permanent magnet unit, an electromagnet unit, a conductive adjusting unit, a wire unit and a wheel unit on a stand plate, the effective fruit exhibition effect is achieved. The vegetable and fruit exhibition stand has the advantages that the exhibition fixing structure is reasonable and effective, fixing operation is convenient andrapid, the exhibition fixing use range is wide, fruits with different sizes can be effectively fixed, the blocking area is small during fixing, the area of exposed and exhibited parts is large, the exhibition effect is good, the rolling use effect of the exhibition stand is good, and exhibition and notification can be conducted in real time on field edges.

Owner:ANHUI JISHAN ECOLOGICAL AGRI CO LTD

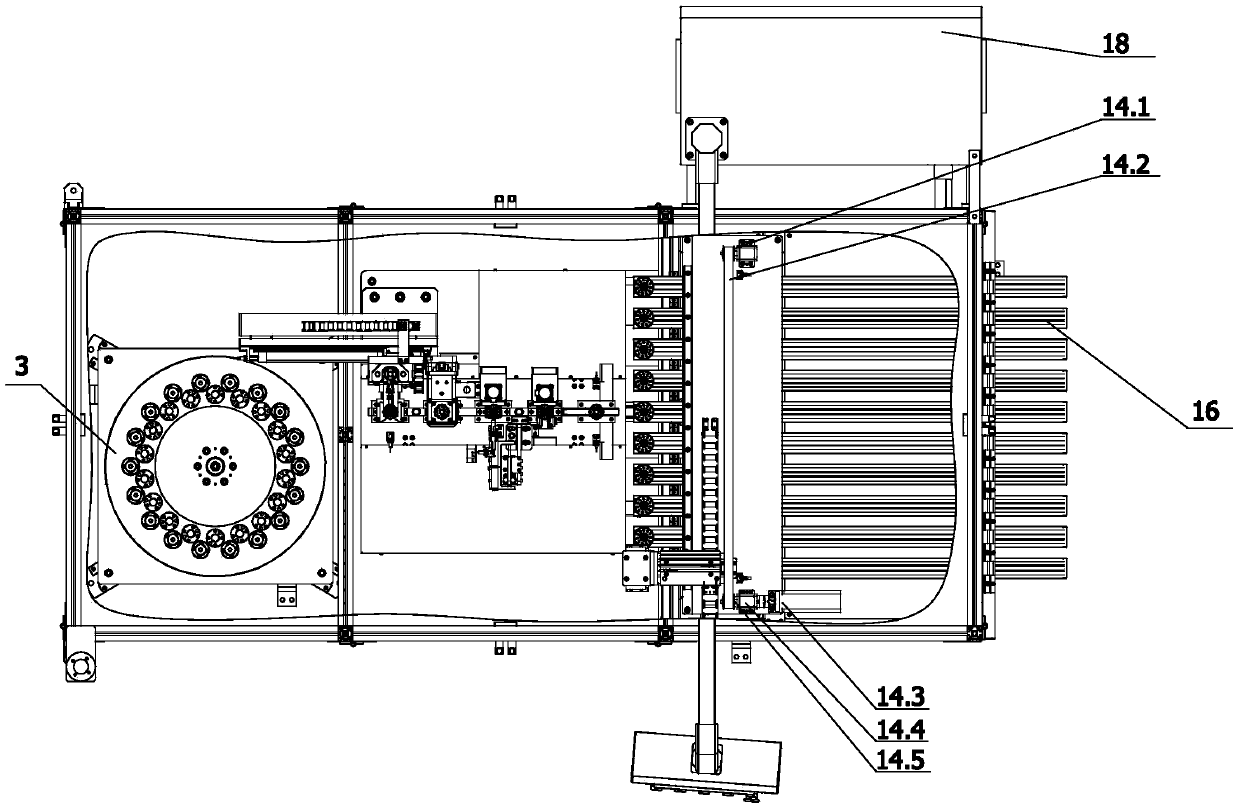

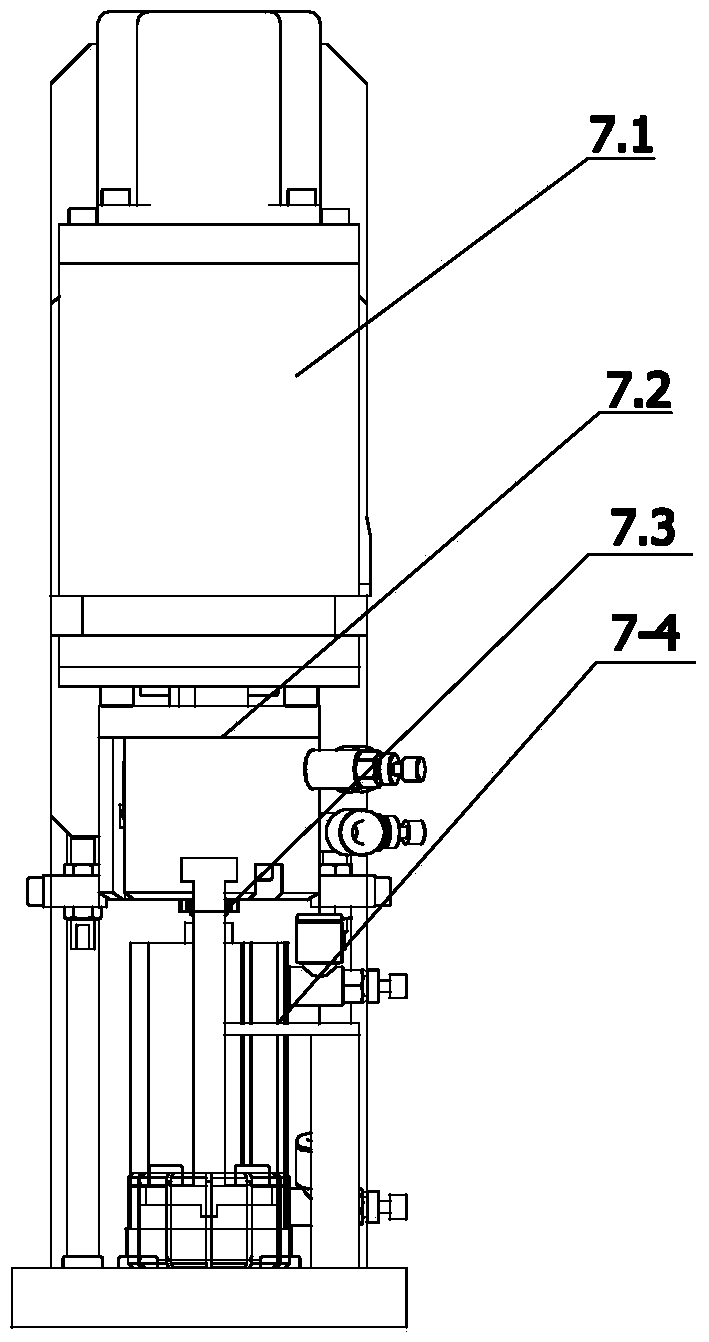

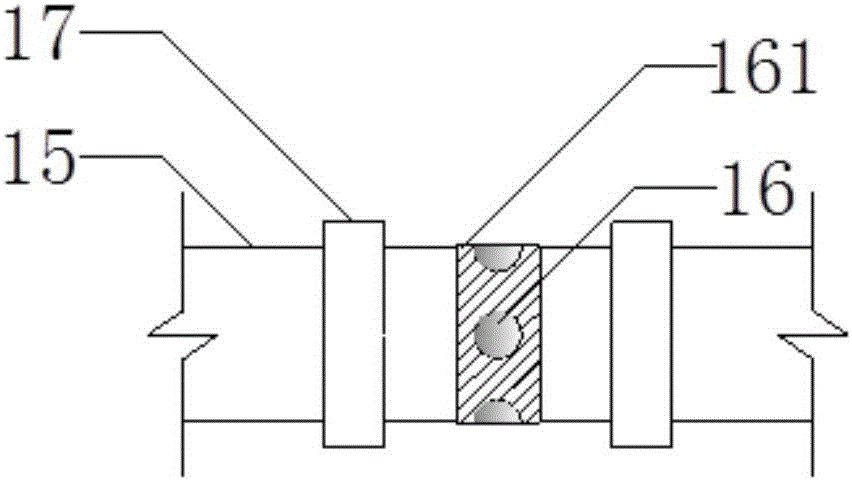

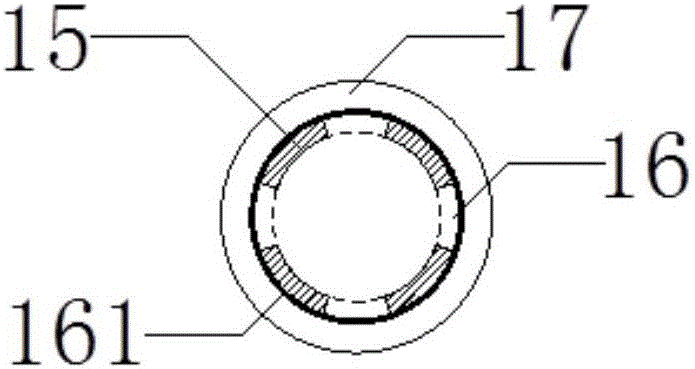

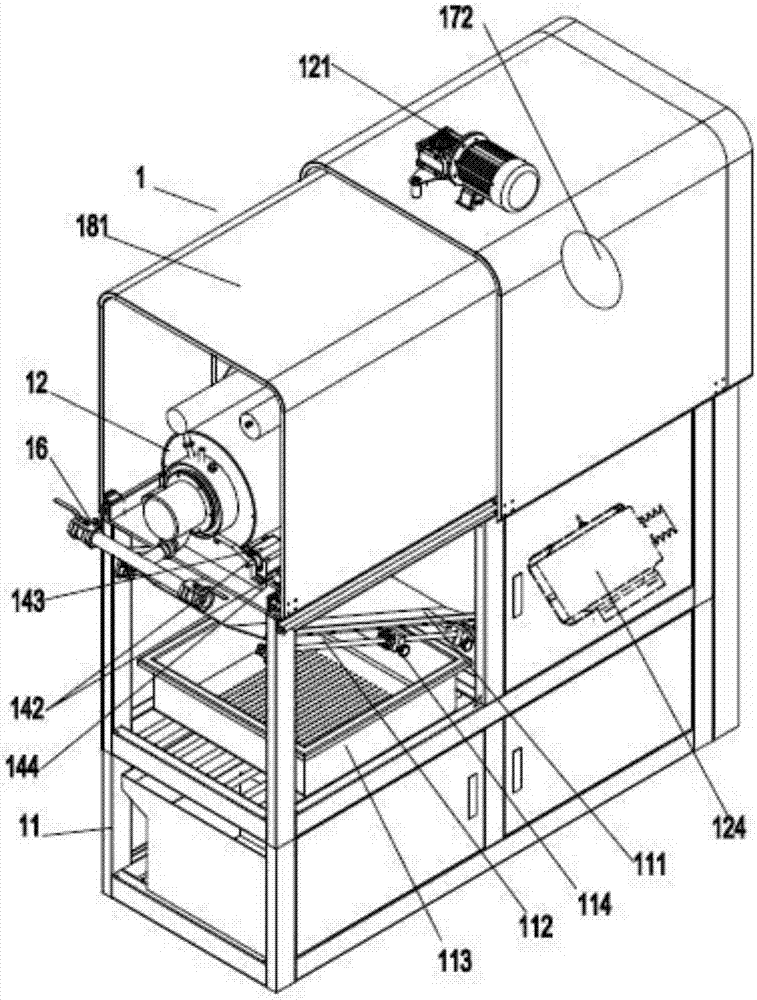

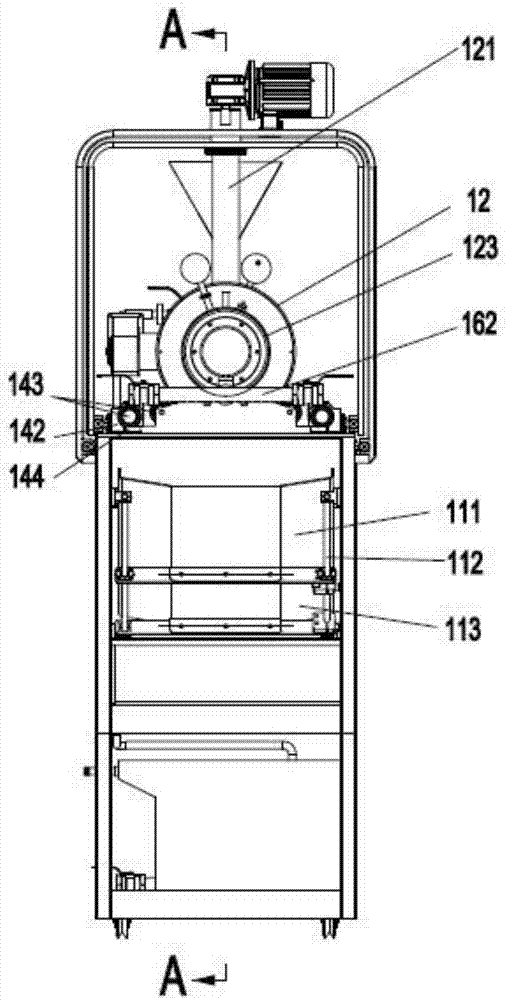

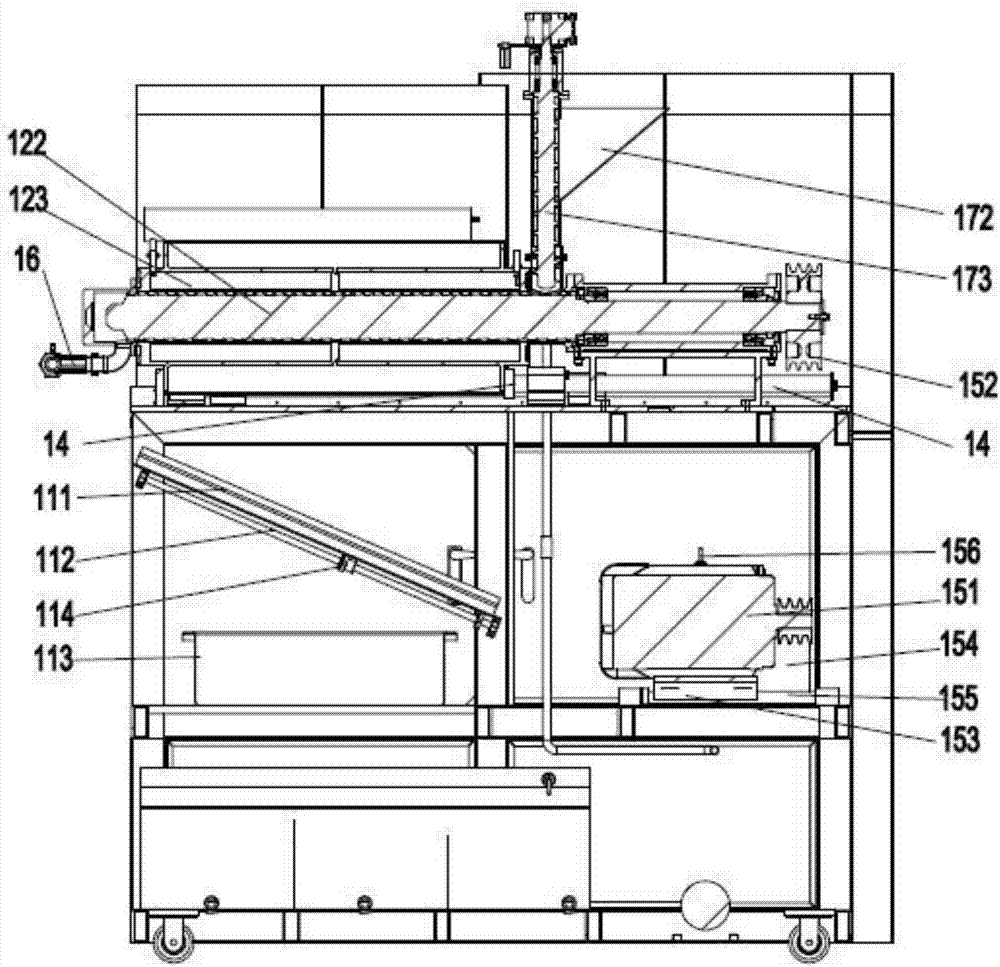

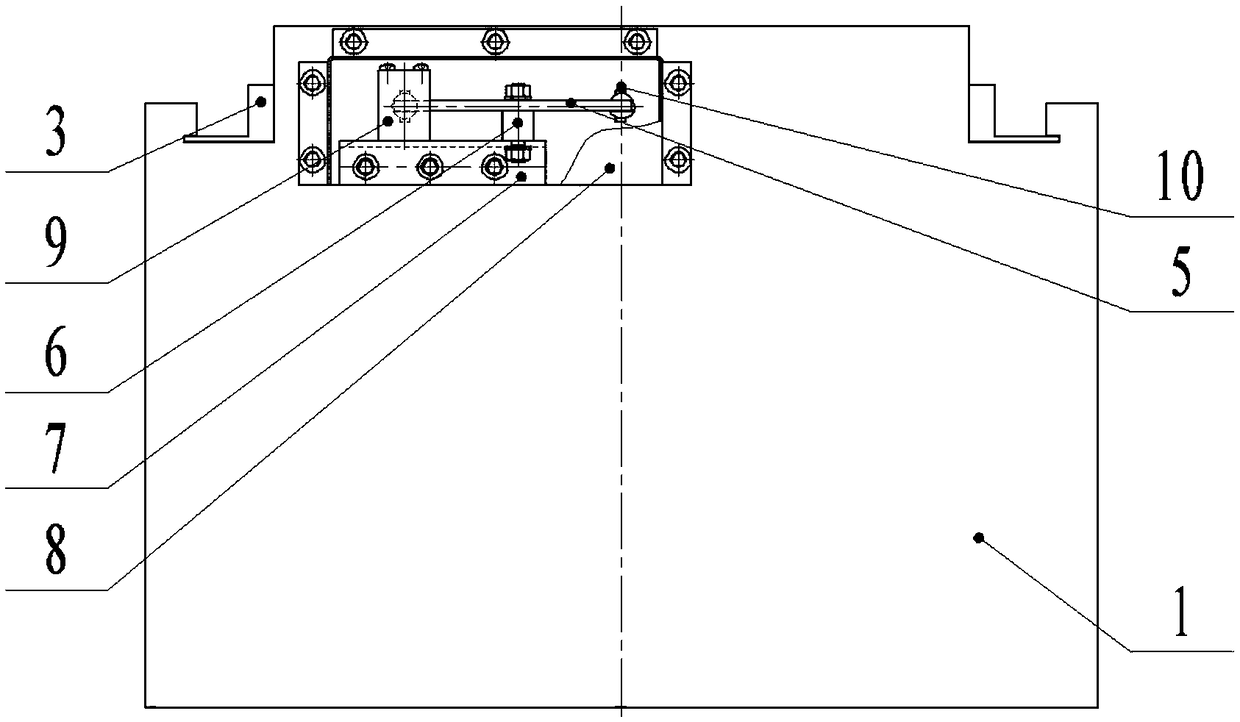

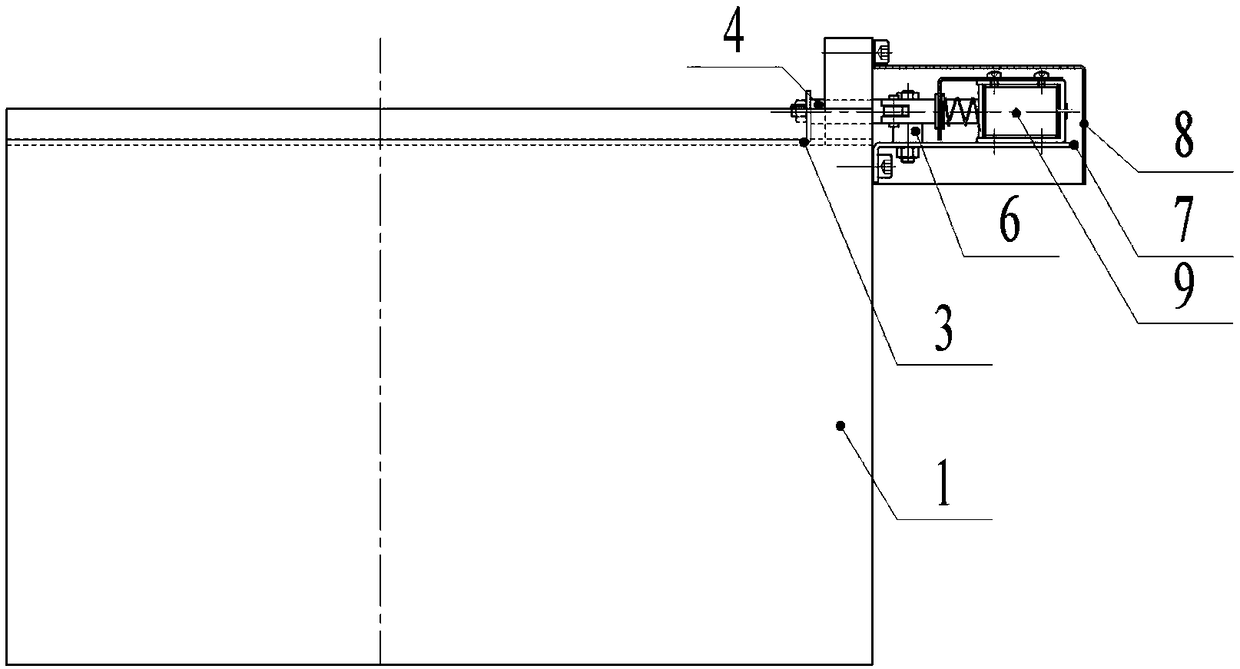

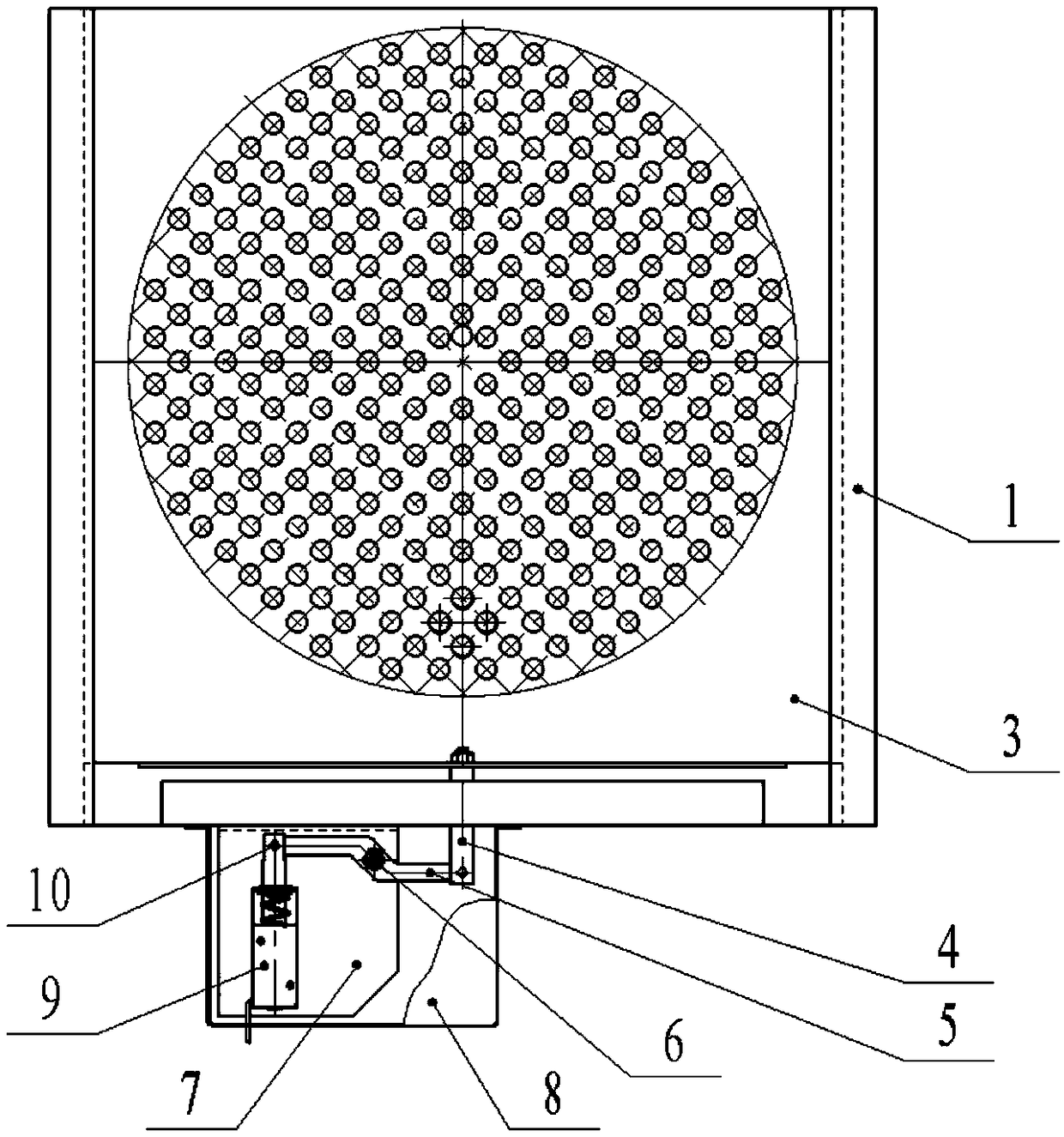

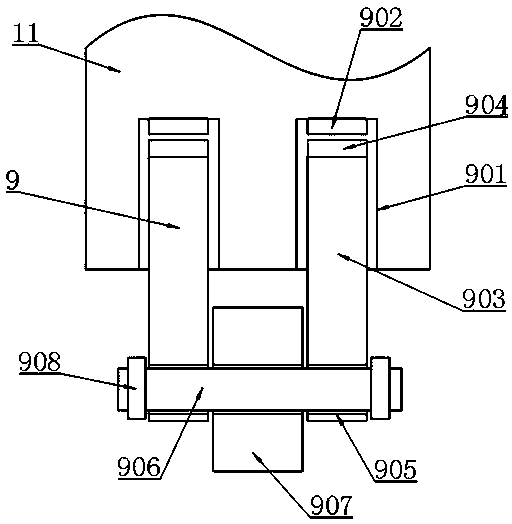

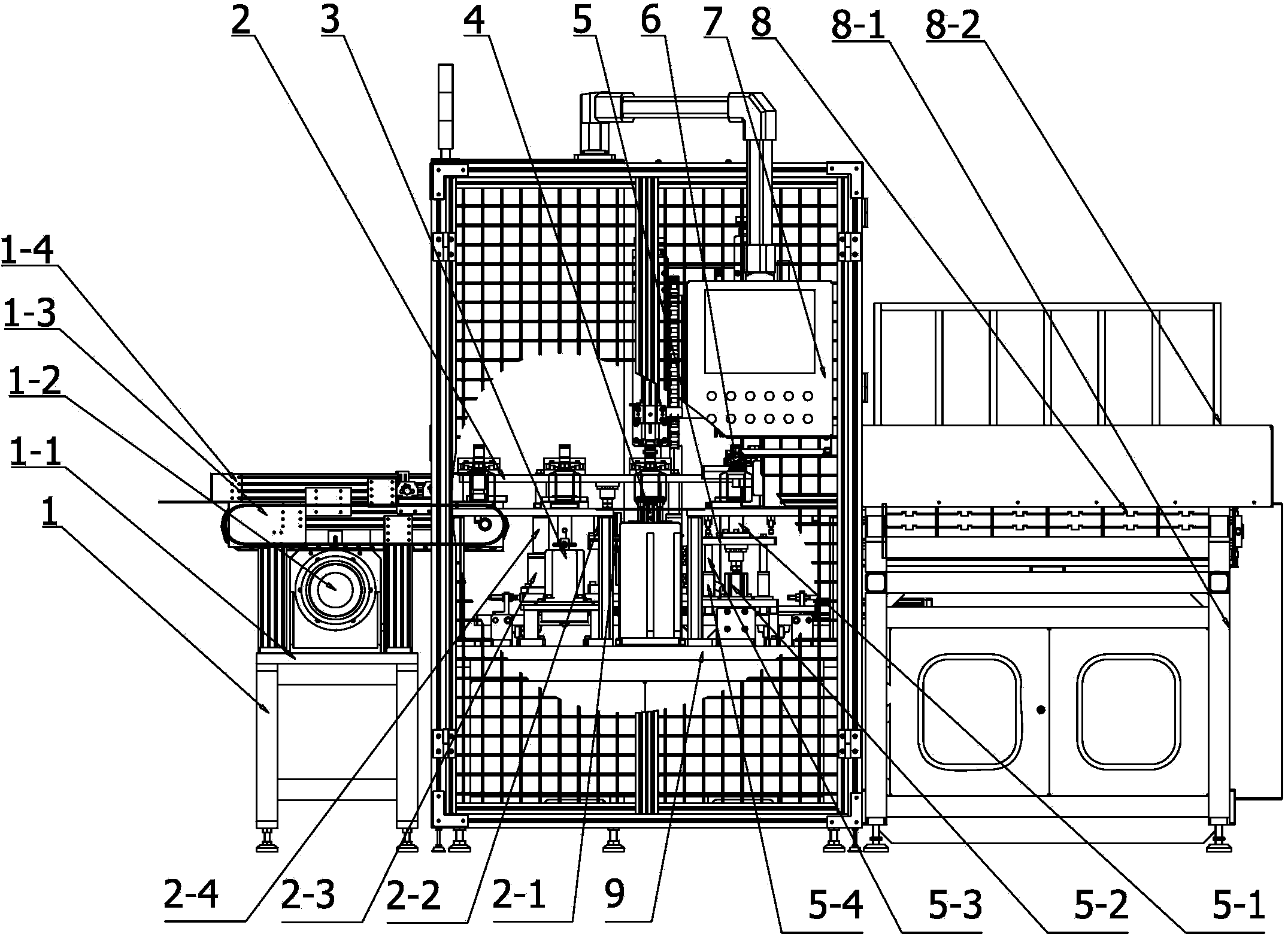

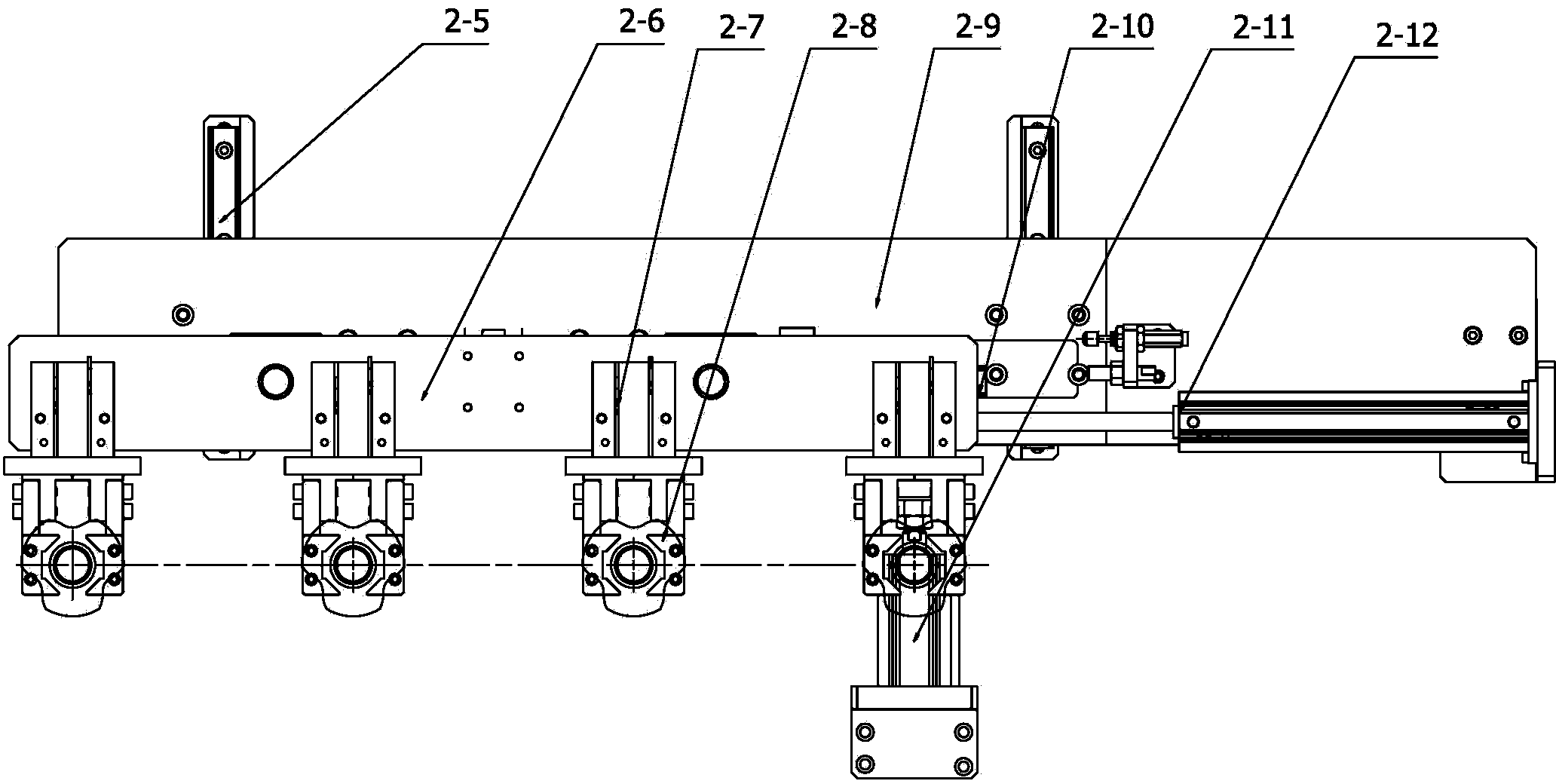

Constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine

ActiveCN104307764ARealize automatic feeding processHigh measurement accuracyUsing electrical meansSortingGroove widthUniversal joint

The invention belongs to the field of mechanical equipment, and relates to equipment for measuring, grouping and engraving a constant-velocity universal joint in an automobile transmission system, in particular to a constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine. The constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine comprises a machine frame, wherein a feeding mechanism is arranged at a feeding end of the machine frame; a discharging mechanism is arranged at a discharging end of the machine frame; a transferring mechanism is arranged on the machine frame; a rotary positioning mechanism, a groove width measuring mechanism and a lifting mechanism are sequentially arranged bellow the transferring mechanism; an engraving positioning mechanism and an engraving mechanism are arranged above the lifting mechanism; an electric control box is arranged on the side surface of the machine frame; an operation box is connected with the electric control box through a cantilever arm. The constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine is convenient and quick to operate and remodel; by switching a model simply and selecting a measuring picture menu, the model can be switched, so that the aim of producing multiple varieties in turns can be achieved; the whole measuring and grouping process requires no human participation and is completed automatically by the constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine.

Owner:WUXI MEASURE MACHINE MFR

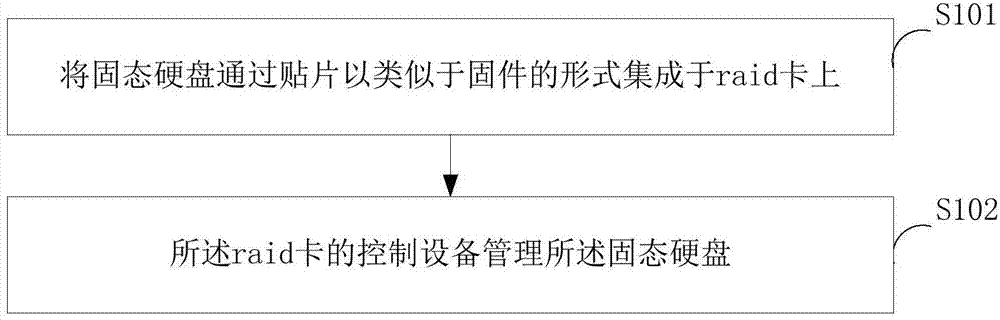

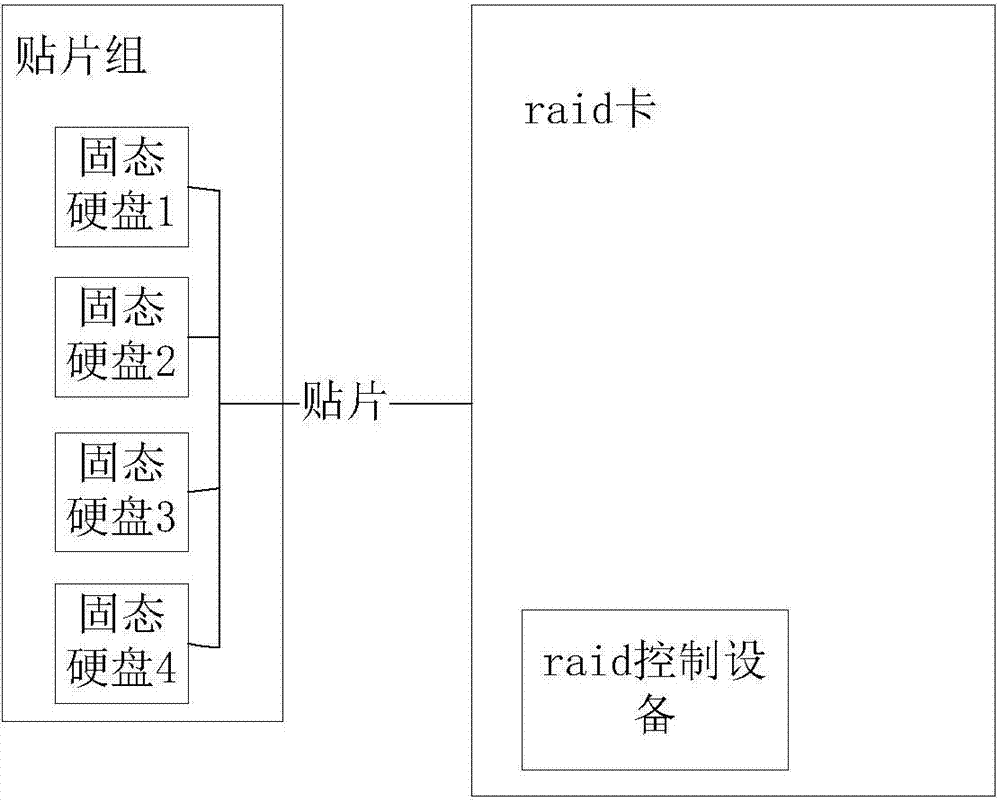

Combined method of disk array and disk array

InactiveCN104765567AImprove read and write speedRealize integrationInput/output to record carriersRAIDSolid-state storage

The invention is applicable to the field of a solid storage and server storage technology, and provides a combined method of a disk array and a disk array. The method comprises the steps of integrating a solid state hard disk on a raid card through a paster in such a firmware-like way, and managing the solid hard disk by control equipment of the raid card. According to the combined method of the disk array provided by the invention, the paster is glued on the raid card to form the disk array which is higher in redundant capacity reading and writing speed; meanwhile, the integration of the solid hard disk and the raid card can be realized to be more convenient and quicker for operation and application.

Owner:深圳中电长城信息安全系统有限公司

Fermentation bin with easy-discharging function

InactiveCN108715798AConvenient and quick operabilityEasy dischargeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The invention discloses a fermentation bin with an easy-discharging function. The fermentation bin comprises a cylindrical bin body, a feeding port is formed at the upper end of the bin body, a pedestal is arranged at the lower end of the bin body, a discharging port is arranged at the center of the pedestal at the lower end of the bin body, and a stirrer is arranged inside the bin body. The stirrer is capable of realizing normal stirring for fermentation by rotating forwards and capable of automatically assisting in discharging by rotating backwards, dry materials and moist materials can be discharged separately, and the fermentation bin with the easy-discharging function is quite practical.

Owner:江苏雪枫环保科技有限公司

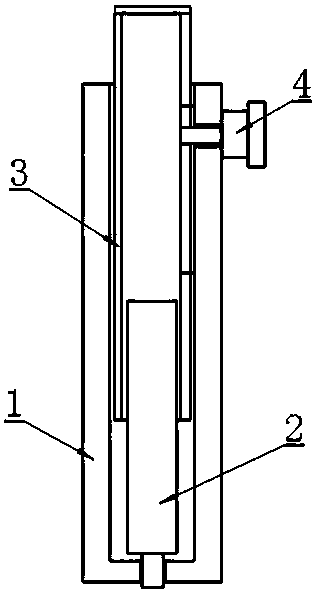

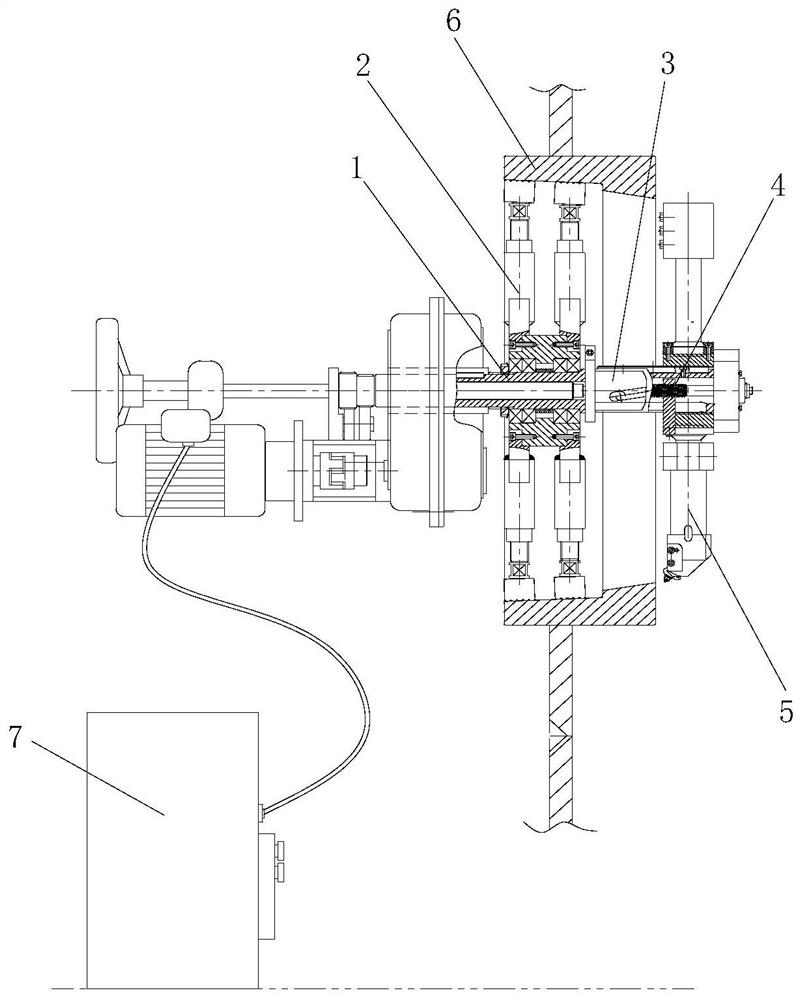

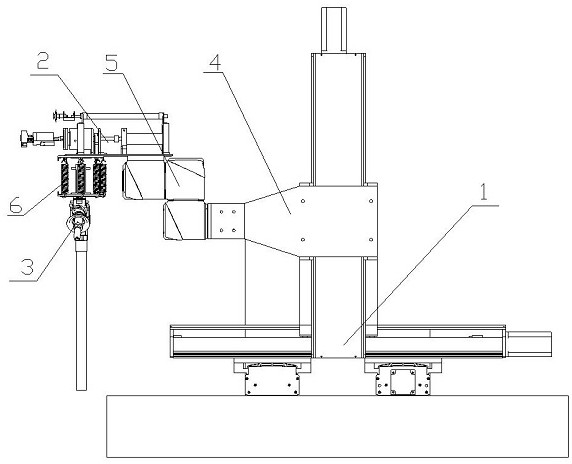

Boring device for tuyere large sleeve of blast furnace

PendingCN113510264AImprove sealingExtended service lifeAutomatic control devicesMeasurement/indication equipmentsScrew threadIndustrial engineering

The embodiment of the invention provides a boring device for a tuyere large sleeve of a blast furnace. The boring device comprises a power system, a main shaft assembly, a positioning support, a feeding frame, a broach mechanism and a tool rest assembly, wherein the main shaft assembly comprises a hollow main shaft, and the main shaft is in transmission connection with the power system; the positioning support is connected with the main shaft assembly, and the positioning support is used for positioning the main shaft relative to the tuyere large sleeve; the feeding frame is fixedly connected with the main shaft, a strip-shaped groove is formed in the feeding frame, and the included angle between the strip-shaped groove and the axis of the main shaft is equal to the machining inclination of the tuyere large sleeve; the broach mechanism comprises a feeding lead screw, the feeding lead screw is arranged in the main shaft in a penetrating mode, and the feeding lead screw is in transmission connection with the main shaft; the tool rest assembly is in threaded connection with the feeding lead screw, and the feeding lead screw drives the tool rest assembly to conduct axial feeding; and the tool rest assembly is in sliding fit with the strip-shaped groove of the feeding frame, and when the tool rest assembly conducts axial feeding, the feeding frame drives the tool rest assembly to conduct radial feeding. The boring device has the characteristics of uniform cutting and convenience in operation.

Owner:QINHUANGDAO QINYE HEAVY IND

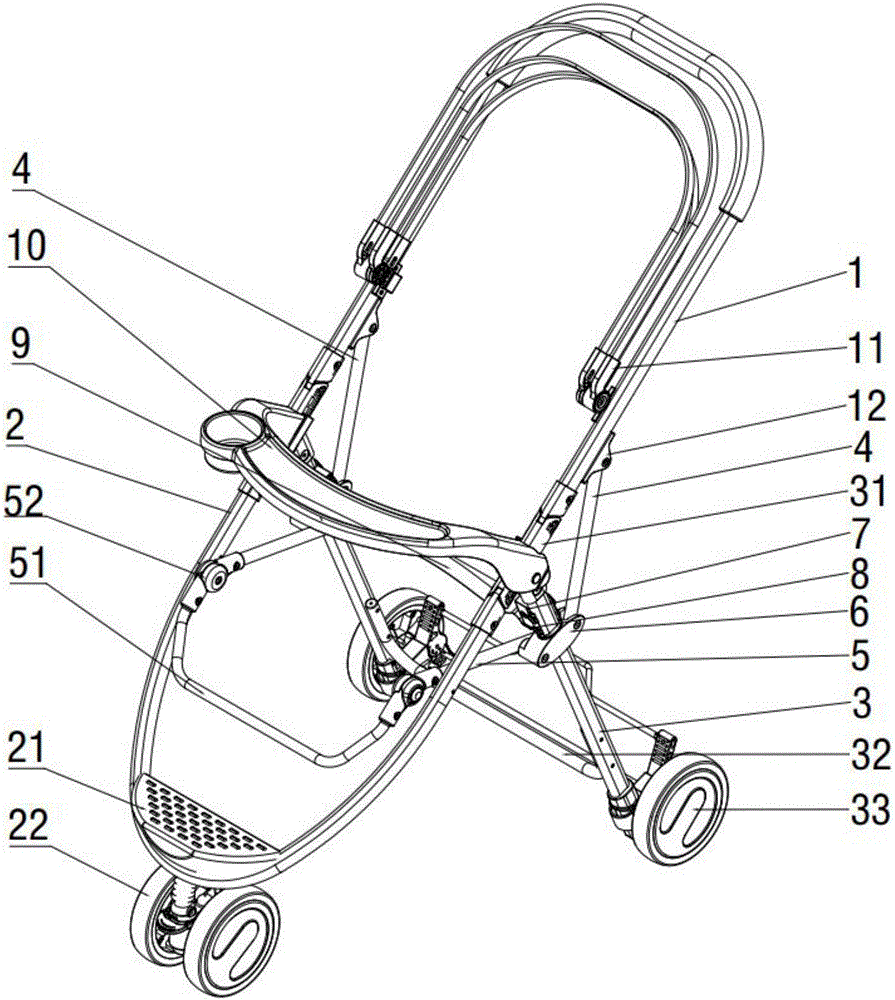

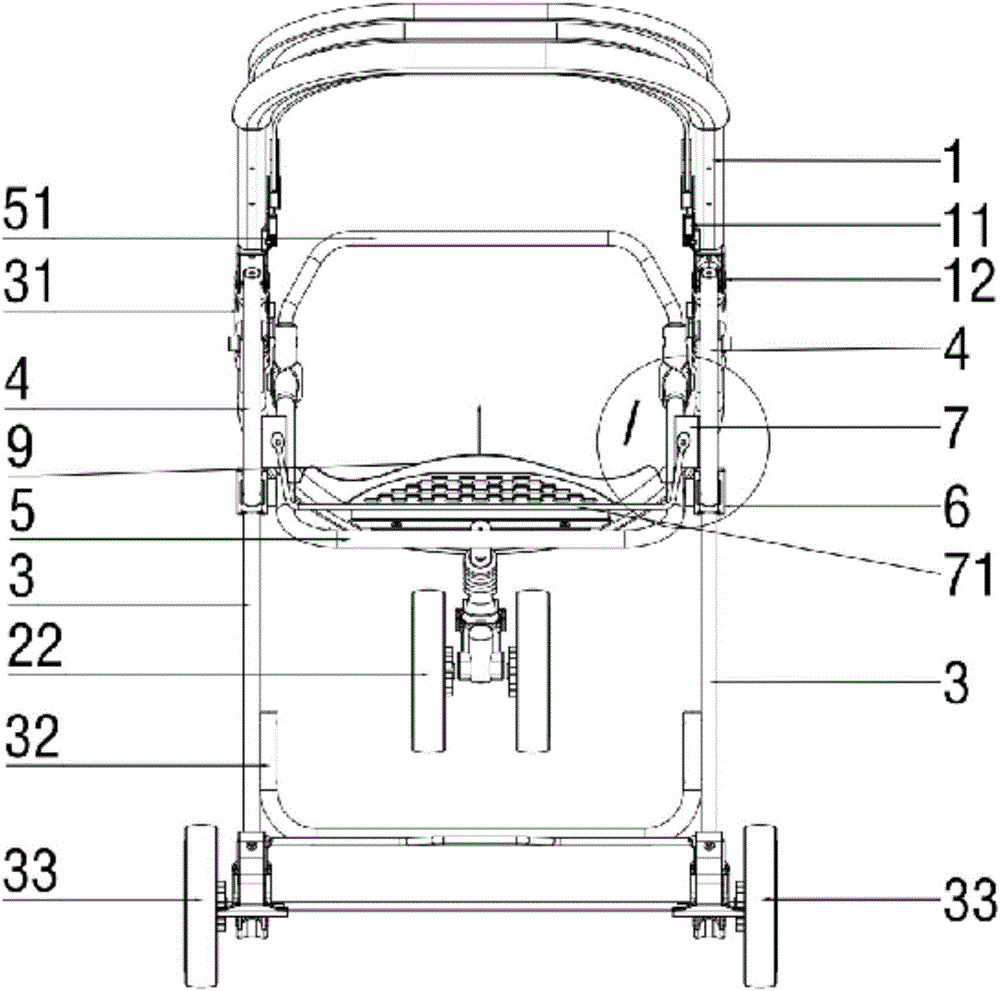

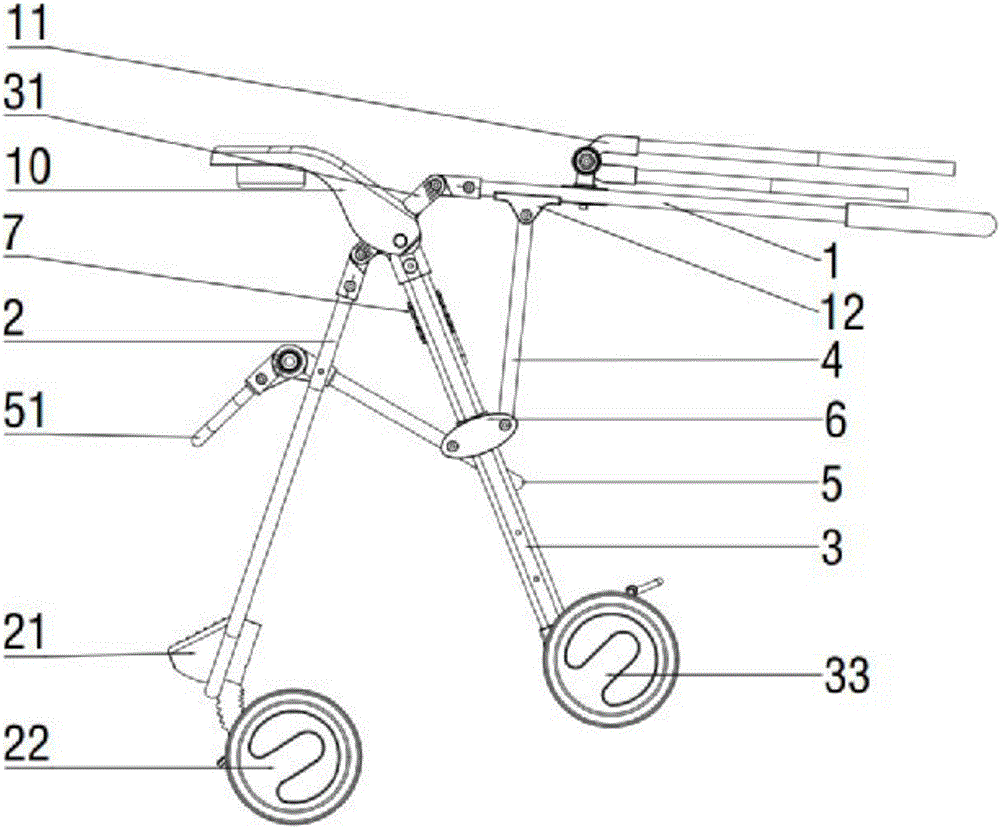

Baby stroller capable of being locked in collapsible manner

InactiveCN106275037ANovel structureEasy to operateCarriage/perambulator with multiple axesHand cartsPipe fittingEngineering

The invention provides a baby stroller capable of being locked in a collapsible manner. A frame comprises a push rod, a front foot pipe fitting, rear foot pipe fittings, rear supporting rods, a seat cushion pipe fitting, sliding parts and latch fasteners; the push rod and the rear foot pipe fitting are both rotationally connected with joint connectors through revolute joints, and the rear foot pipe fittings are inserted into the joint connectors, the push rod is connected with the sliding parts through the rear supporting rods, the front foot pipe fitting is connected with the sliding parts through the seat cushion pipe fitting, the sliding parts penetrate through the rear foot pipe fittings, and can slide up and down, so that the frame can be folded or unfolded; the latch fasteners are correspondingly buckled with the sliding parts, thus the frame is unfolded stably and fixedly. The baby stroller capable of being locked in the collapsible manner disclosed by the invention is novel and simple in structure, small in folding size and convenient to carry.

Owner:SUZHOU JIABAO BASSINET CO LTD

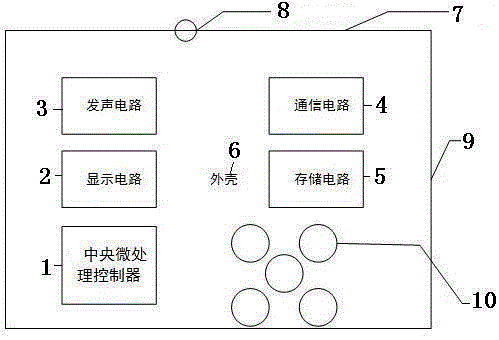

Four-wheel positioning intelligent terminal based on wireless communication

InactiveCN105259825AConvenient and quick operabilityEasy and fast controlProgramme controlComputer controlKey pressingTouchscreen

Provided is a four-wheel positioning intelligent terminal based on wireless communication. The four-wheel positioning intelligent terminal comprises a central micro-processing controller, a display circuit, a sounding circuit, a communication circuit, a storage circuit, a housing, a power interface, a start button, a touch screen, and a functional button. The display circuit, the communication circuit, the storage circuit, and the sounding circuit are connected with the central micro-processing controller. The display circuit, the communication circuit, the storage circuit, the sounding circuit, and the central micro-processing controller are all arranged in the housing. The power interface, the start button, and the functional button are arranged on the housing. The touch screen is connected with the display circuit and is arranged on the surface of the four-wheel positioning intelligent terminal. The four-wheel positioning intelligent terminal may help a repairer conveniently, fast, and remotely operate and control a host computer, check a detection result, and improve work efficiency.

Owner:JIANGXI NORMAL UNIV

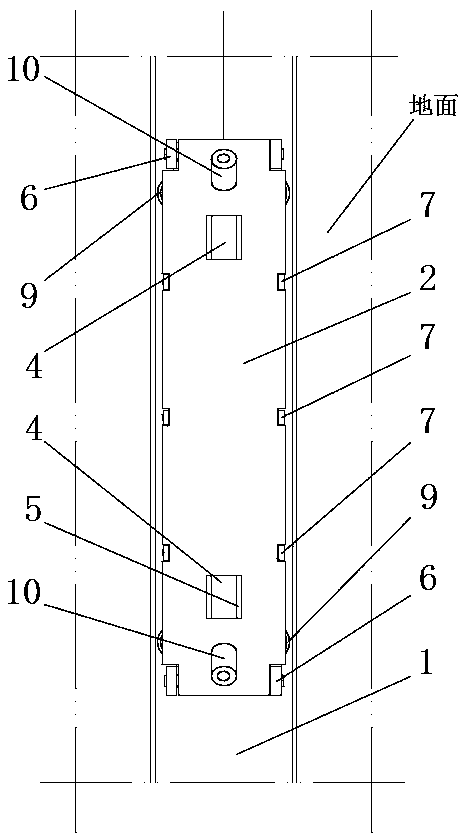

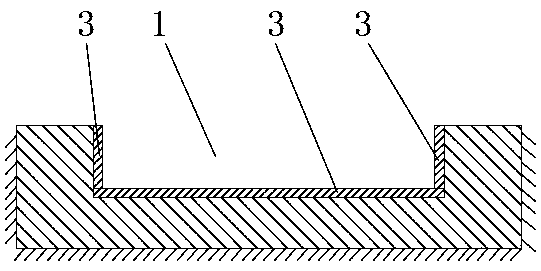

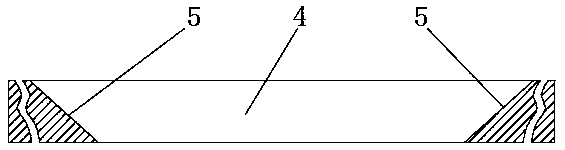

Mechanism for transferring warp beam among textile workshops

PendingCN107839743AQuick installationConvenient and quick operabilityHand carts with multiple axesEngineeringStructural engineering

The invention relates to the technical field of warp beam transferring, in particular to a mechanism for transferring warp beam among textile workshops. The mechanism a rectangular rail groove in a floor of each workshop and a trolley in the rectangular rail groove, the rectangular rail groove is communicated with each workshop, the trolley comprises a mounting plate, rollers are arranged on the mounting plate to enable the trolley to move along the rectangular rail groove, the upper surface of the mounting plate is flush with the floor, the length of the mounting plate is larger than that ofeach warp beam, and each warp beam can be rolled from the lateral side to be mounted on the mounting plate. The mechanism is structurally simple and practical, convenient and quick in mounting and transferring operation, safe and reliable, quickness in mounting of the warp beams on the mechanism for transferring is realized, and labor intensity of workers is reduced.

Owner:SICHUAN YUYANG TEXTILE

Robot oil filling or gas filling method

PendingCN113880033AImprove refuelingImprove experienceLiquid transferring devicesFuel tankVisual recognition

The invention discloses a robot full-automatic oil filling or gas filling method. The method comprises the following steps of 1, vehicle recognition; 2, vehicle guiding, wherein a vehicle is guided to enter an area to be subjected to oil filling or gas filling; 3, cover opening; 4, gun insertion, wherein a joint system 5 rotates, so that an oil filling or gas filling mechanism 3 faces forwards, and the oil filling or gas filling mechanism 3 is inserted into an opening of an oil tank or a gas storage tank under guidance of a visual recognition device; 5, filling; 6, cover closing; and 7, after the step 6 is completed, the vehicle is reminded that the vehicle can leave. According to the robot full-automatic oil filling or gas filling method, unmanned full-automatic oil filling or gas filling operation can be achieved.

Owner:JIANGYIN FUREN HIGH TECH

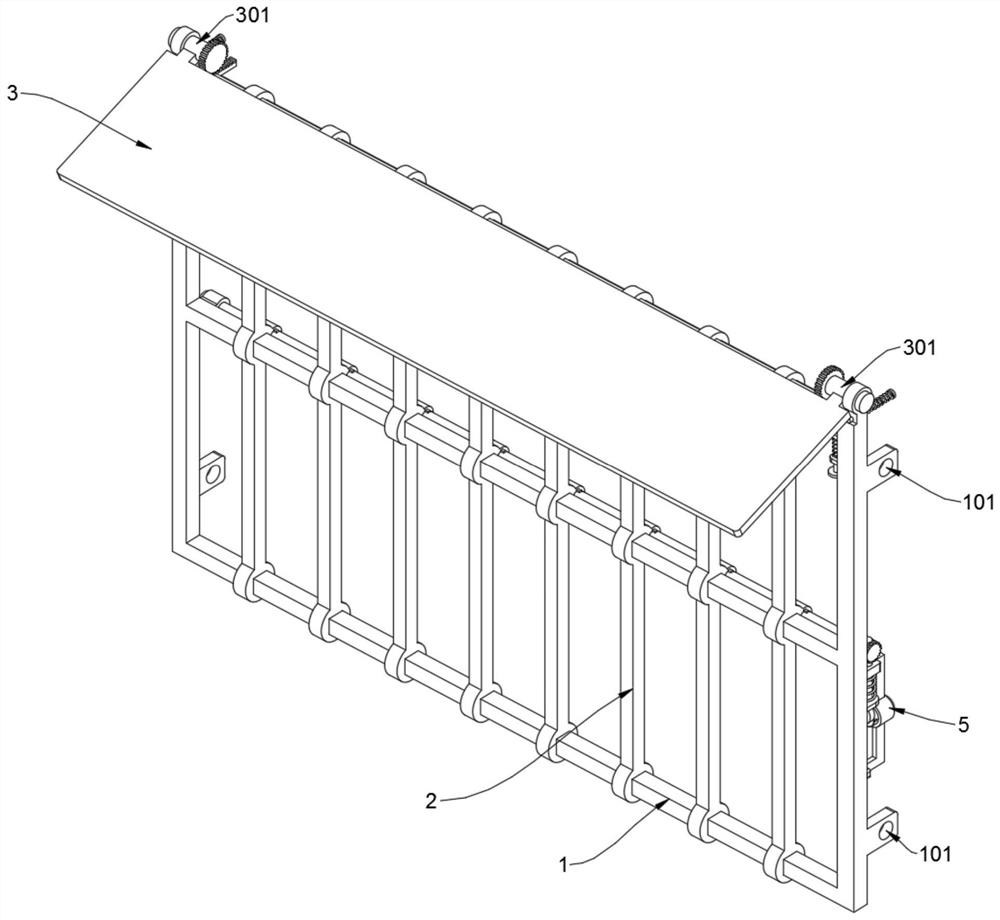

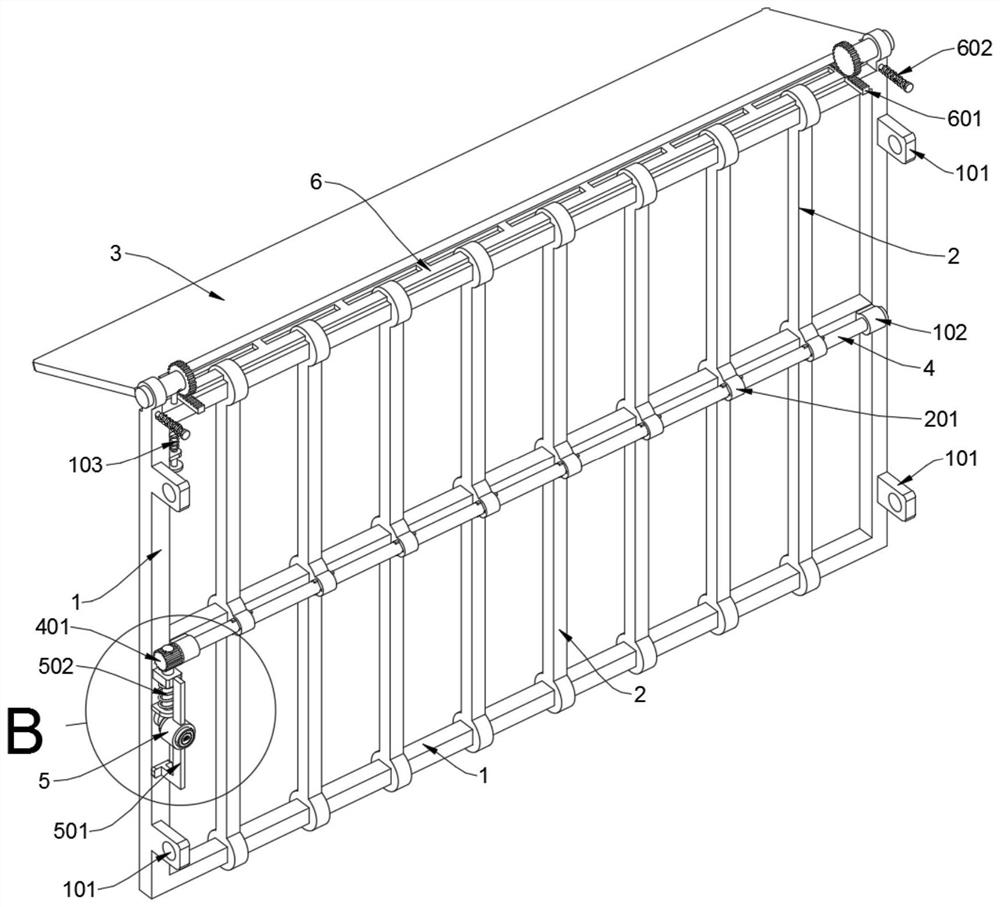

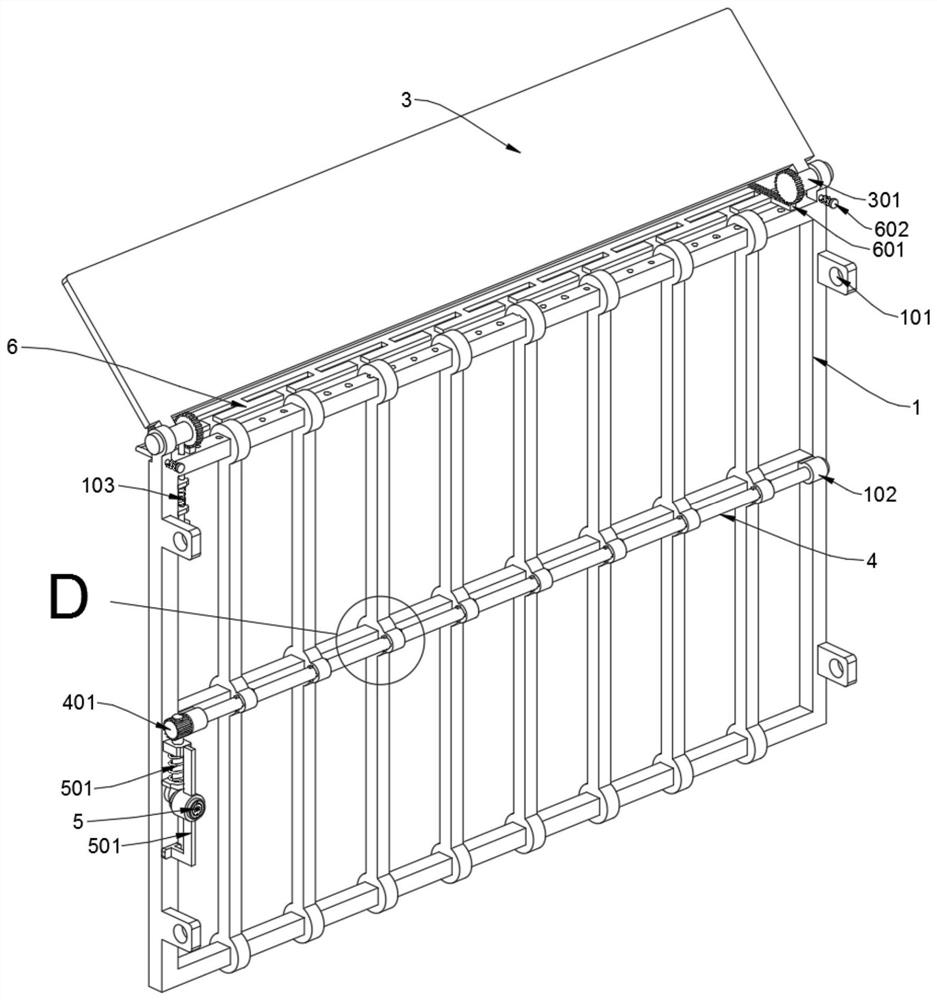

Fire-resistant stainless steel door and window based on construction

ActiveCN111720024AQuick and easy releaseConvenient and quick operabilityShutters/ movable grillesFireproof doorsForeign matterConstruction engineering

The invention discloses a fire-resistant stainless steel door and window based on construction, and relates to the technical field of stainless steel doors and windows. The problems that during production of existing doors and windows, access or escape doorways need to be reserved, the doorways are mostly formed by welding and installed on anti-theft windows in a hinged mode, and the production steps are complicated, so as to increase overall production difficulties of the anti-theft windows are solved. The fire-resistant stainless steel door and window based on construction comprises a main window frame, a vertical bracing handrail, a positioning shaft rod and a window lock, the main window frame comprises mounting plates, a positioning sleeve, an inserted rod and a diversion plate, the main window frame is in a rectangular shape as a whole, four mounting plates are symmetrically welded on the back parts of vertical bracing square tubes on the left and right of the main window frame,and the inserted rod is inserted in the inner side position of the top section of the vertical bracing square tube on the left side through a spring in a pushing and penetrating mode. According to thefire-resistant stainless steel door and window based on construction, a cover-blocking frame can block a row of water leakage holes at the top end of the main window frame under a normal use state, so that blockage of transverse bracing square tubes at the top end of the main window frame caused by entering of foreign matters is avoided.

Owner:SHANGHAI TOB INTELLIGENT DOORS & WINDOWS SCI&TECH INC

Intelligent height Increasing frame for computer display

InactiveCN109323088AEasy to useHigh fixed placement stabilityDigital data processing detailsStands/trestlesIntelligent lightingDisplay device

The invention relates to an intelligent height Increasing frame for a computer display. The intelligent height increasing frame comprises supporting columns and a supporting plate, and further comprises a placing groove, elastic ropes, two electromagnet units, adjusting attracting units, sliding grooves, clamping blocks and sliding triggering units, wherein the elastic ropes are arranged on the placing groove, the two electromagnet units are arranged at the positions of the ends of the elastic ropes separately, the adjusting attracting units are arranged on the elastic ropes and are used for tensioning the elastic ropes by attracting the electromagnet units through the magnetic force, the sliding grooves are formed in the side surface of the placing groove, the clamping blocks are arrangedon the sliding grooves in a clamped mode and are used for being connected to the electromagnet units, and the sliding triggering units are arranged in the sliding grooves and are used for enabling the electromagnet units to magnetically attract the adjusting attracting units in a conductive contact mode. The intelligent height Increasing frame has the advantages that a fixing structure for a display base on the height increasing frame is reasonable and effective, the fixing and fixing relieving operation is convenient and rapid, the base fixing and placing stability is high, and the fixing action is flexible and adjustable.

Owner:GUANGZHOU LADE COSMETICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com