Pipe cutter

A technology for cutting pipes and tool holders, which is applied in the direction of pipe shearing devices, knives for shearing machine devices, shearing devices, etc., which can solve the problems of easy scratching of the inner wall of the pipe by chips, easy heating of the cutter head, and poor cutting quality. It achieves the effect of convenient and fast disassembly and operation, reduced working procedures and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

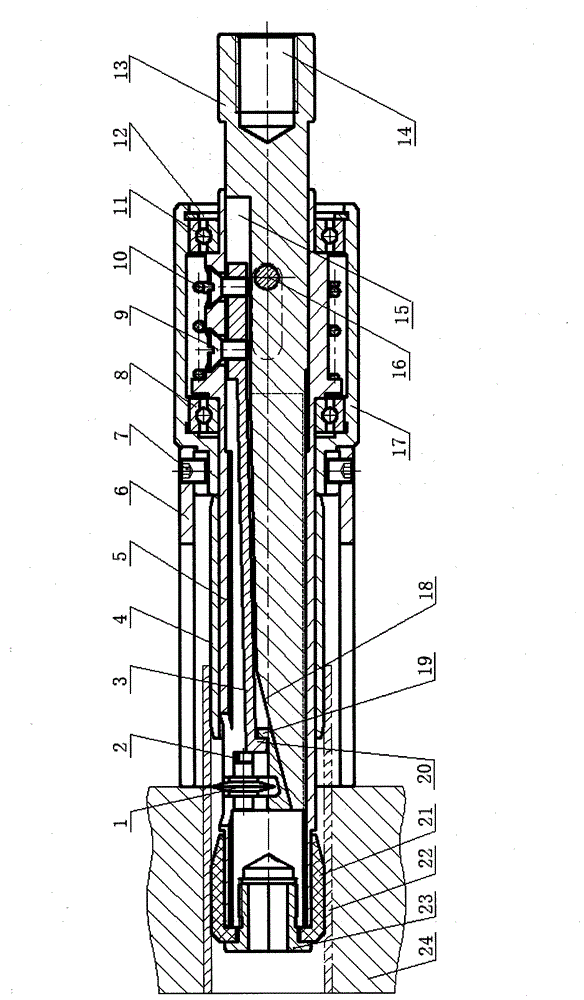

[0015] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

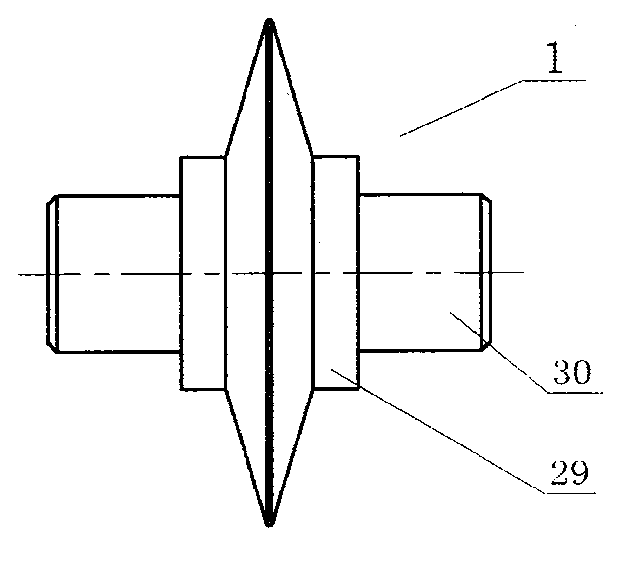

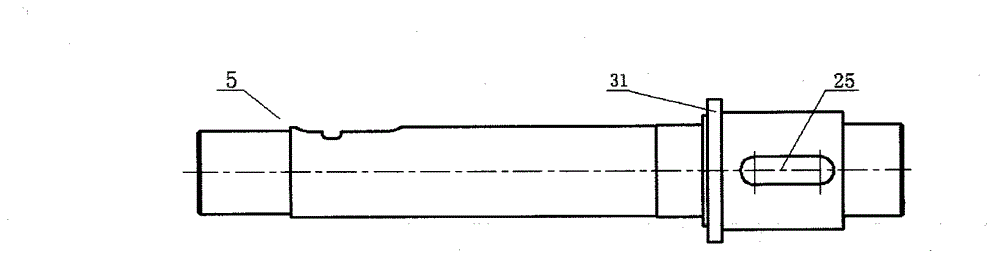

[0016] Depend on Figure 1-Figure 5 It can be seen that the present invention includes a knife rod 13 and a knife holder 2. The knife rod 13 is installed in the middle cavity of the holding sleeve 5, and the upper part is provided with a groove 15, and the groove 15 is equipped with a leaf spring 3, and the leaf spring 3 passes through the screw. 9 is connected to the retaining sleeve 5. The outer sleeve of the retaining sleeve 5 is sheathed with a left rolling bearing 8 and a right rolling bearing 11. The retaining sleeve 5 between the left rolling bearing 8 and the right rolling bearing 11 has an oblong through hole 25 on the wall. A spring 10 is set on the sleeve, the left end of the spring 10 is placed on the shoulder 31 of the retaining sleeve 5, and the right end is placed on the positioning pin 16 inserted in the cutter bar 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com