Oxygen-enriched smelting furnace for treating low-grade multi-metal material

A multi-metal, melting furnace technology, applied in the field of melting furnaces, can solve the problems of difficult processing of metallurgical furnaces, and achieve the effect of convenient and quick installation and disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

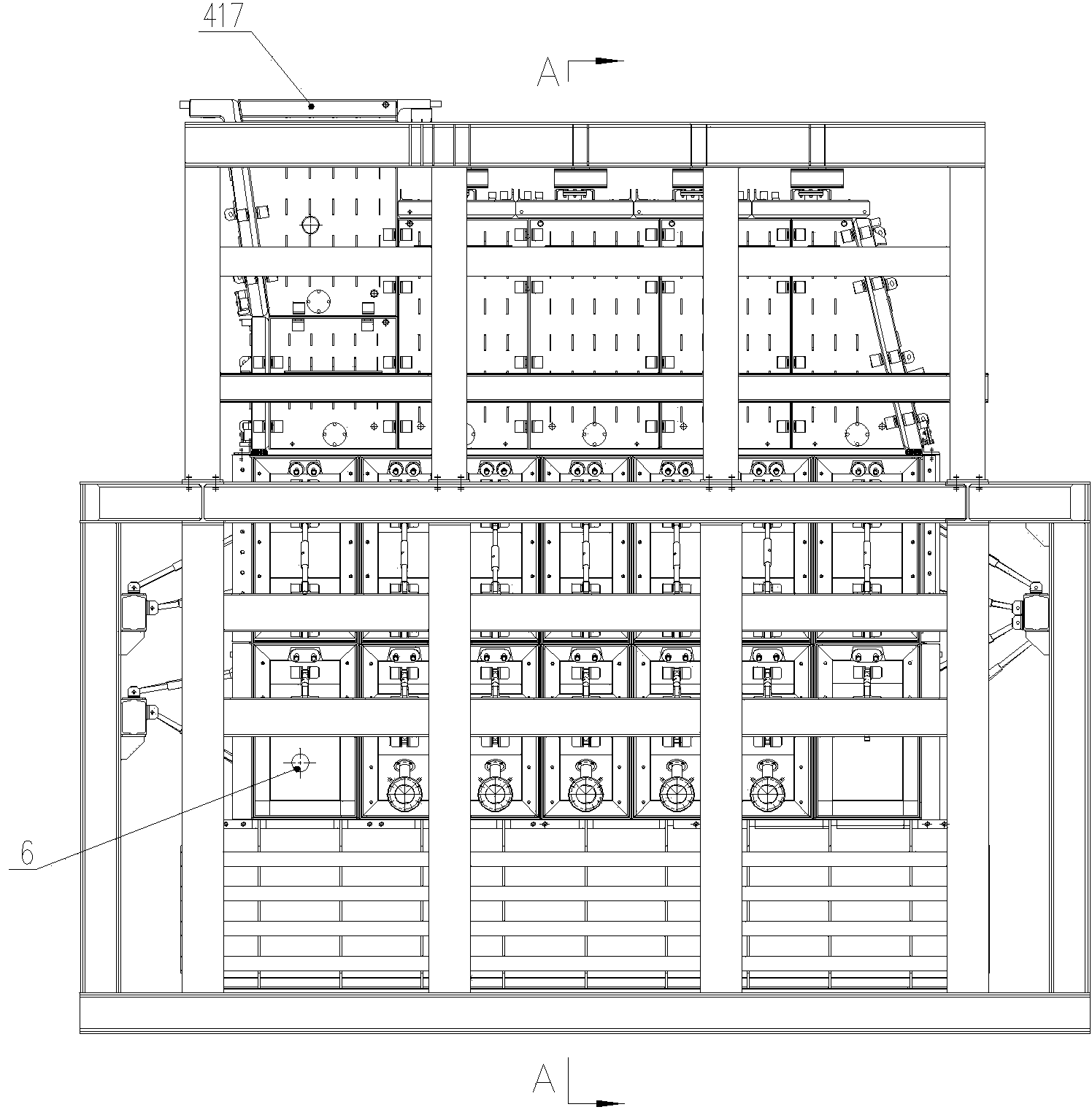

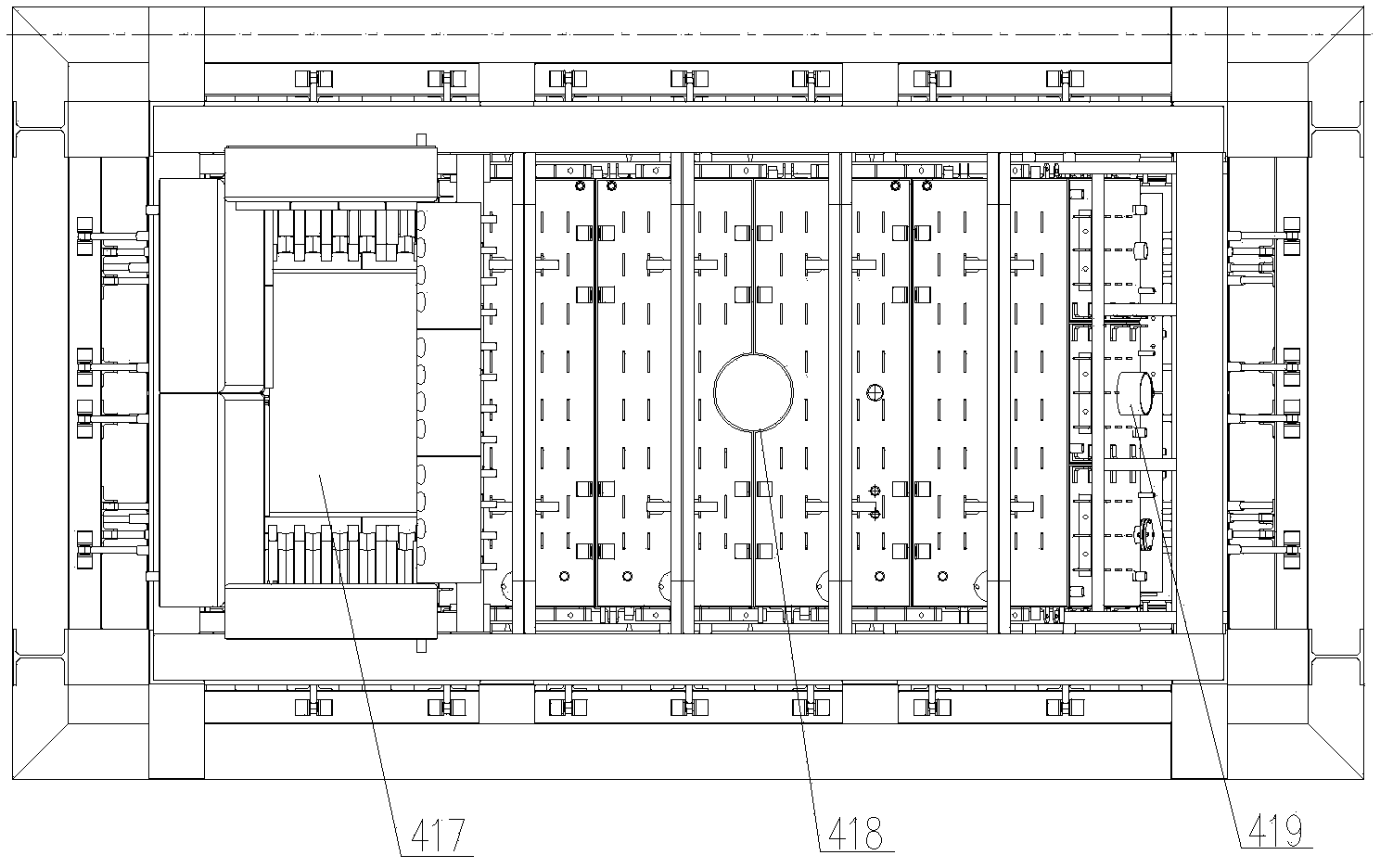

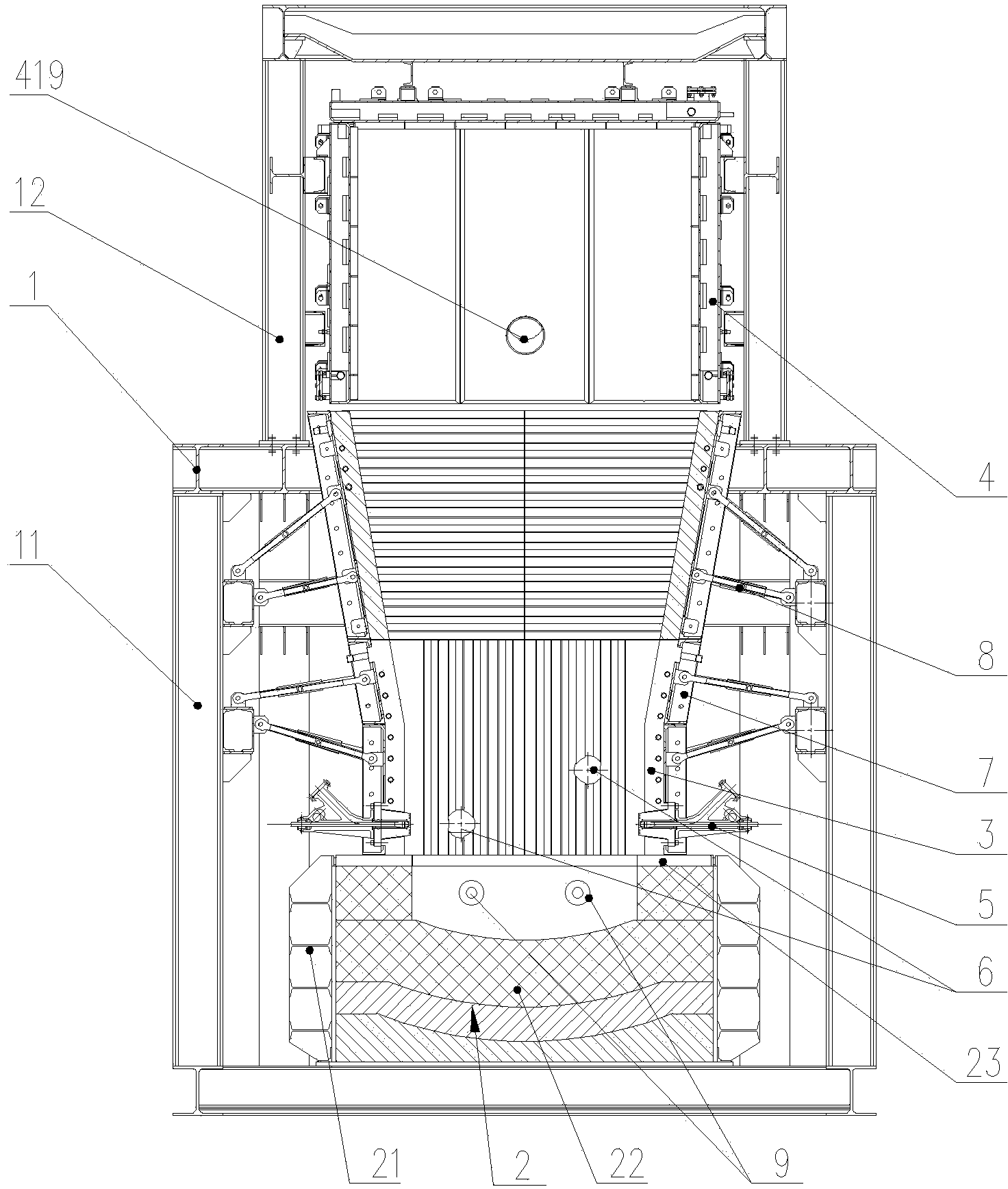

[0027] preferred embodiment, such as Figure 1 to Figure 8 As shown, the oxygen-enriched smelting furnace for processing low-grade polymetallic materials provided by the present invention includes a steel structure frame body 1, a furnace hearth 2 arranged in sequence from bottom to top, a copper water jacket furnace wall 3, a hanging Water jacket 4. The steel frame body 1 includes a support frame 11 for supporting the furnace hearth 2 and the copper water jacket furnace wall 3 at the bottom and a hanger 12 for hanging the hanging steel water jacket 4 at the upper end to bear all the loads produced by the furnace body. The outer wall of the copper water jacket furnace wall 3 has a fixed frame 7, and the fixed frame 7 is fixed by a jack 8 and a support frame 11. Both the hanger 12 and the support frame 11 are made of H-shaped steel, and the hanger 12 and the support frame 11 are connected by detachable bolts.

[0028] Hearth 2 includes masonry 22 , H-shaped steel hoop 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com