Mechanism for transferring warp beam among textile workshops

A warp beam and workshop technology, applied in the field of warp beam transfer mechanism, can solve the problems of harming the health of workers, large warp beam size, time-consuming and labor-intensive problems, and achieves the advantages of convenient installation and transfer operation, low cost and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

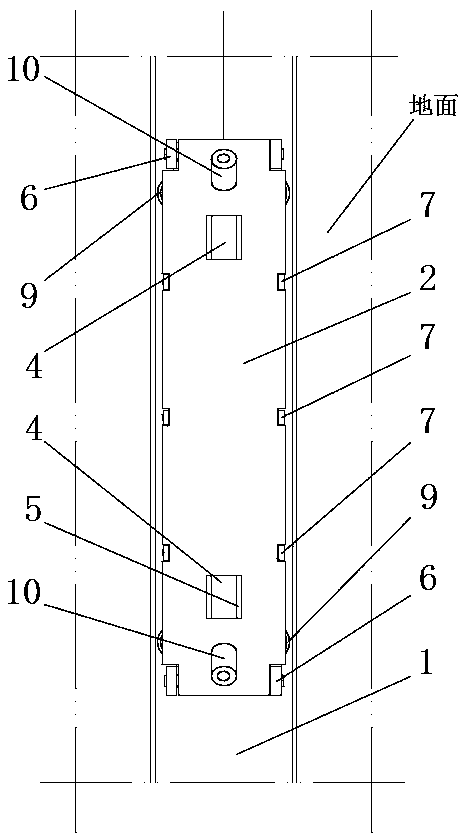

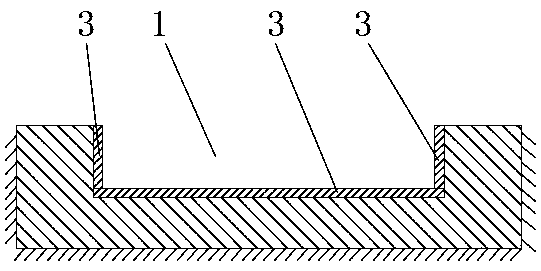

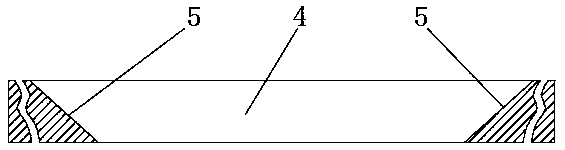

[0022] Such as figure 1 and 2 As shown, the warp beam 12 transfer mechanism between the textile workshops includes a rectangular track groove 1 set up on the floor of each workshop and a trolley arranged in the rectangular track groove 1. The rectangular track groove 1 communicates with each workshop, and the trolley includes a mounting plate 2 , the mounting plate 2 is made of steel, the mounting plate 2 is provided with rollers, so that the trolley can move along the rectangular track groove 1, the rolling wheels can be specifically set as rolling bearings, the upper surface of the mounting plate 2 is flush with the ground, and the length of the mounting plate 2 is greater than Warp beam 12 length, warp beam 12 can be installed on the mounting plate 2 by rolling from the side, further, the bottom and two sides of rectangular mounting groove are all fixedly provided with steel plate 3, the upper surface of side steel plate 3 is flush with the ground, lifts The compressive st...

Embodiment 2

[0027] Such as figure 1 and 2 As shown, on the basis of Embodiment 1, the front and rear ends of the left and right sides of the mounting plate 2 are all rotated to be provided with horizontal guide wheels 9, and the horizontal guide wheels 9 on both sides are symmetrical, and there are four horizontal guide wheels 9 in total. The rotation axis of guide wheel 9 is perpendicular to the ground, and horizontal guide wheel 9 is close to big roller 6, and the distance between the outer ends of both sides corresponding horizontal guide wheel 9 is greater than mounting plate 2 widths, makes the wheel surface of horizontal guide wheel 9 can be with The sides of the rectangular track groove 1 are in contact, and when the wheel surface of the horizontal guide wheel 9 can be in contact with the side of the rectangular track groove 1, the large roller 6 does not contact the side of the rectangular track groove 1. When the trolley advances, when the horizontal guide wheel When the wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com