Rapid locking-disengaging coupling element

A technology of connector plugs and connector sockets, which is applied in the direction of connection, two-part connection devices, parts of connection devices, etc., and can solve problems such as inability to realize fast plug-in and separation, long operation time of connectors, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

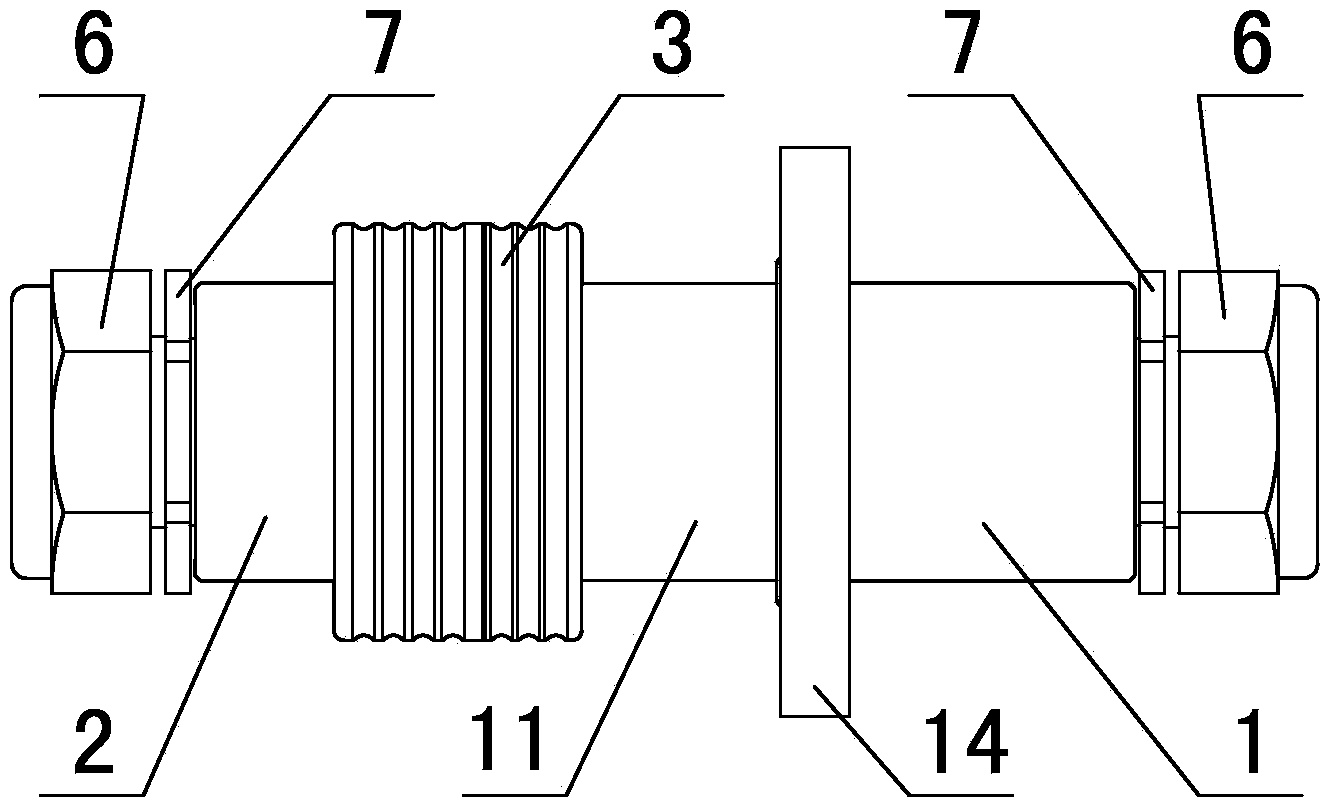

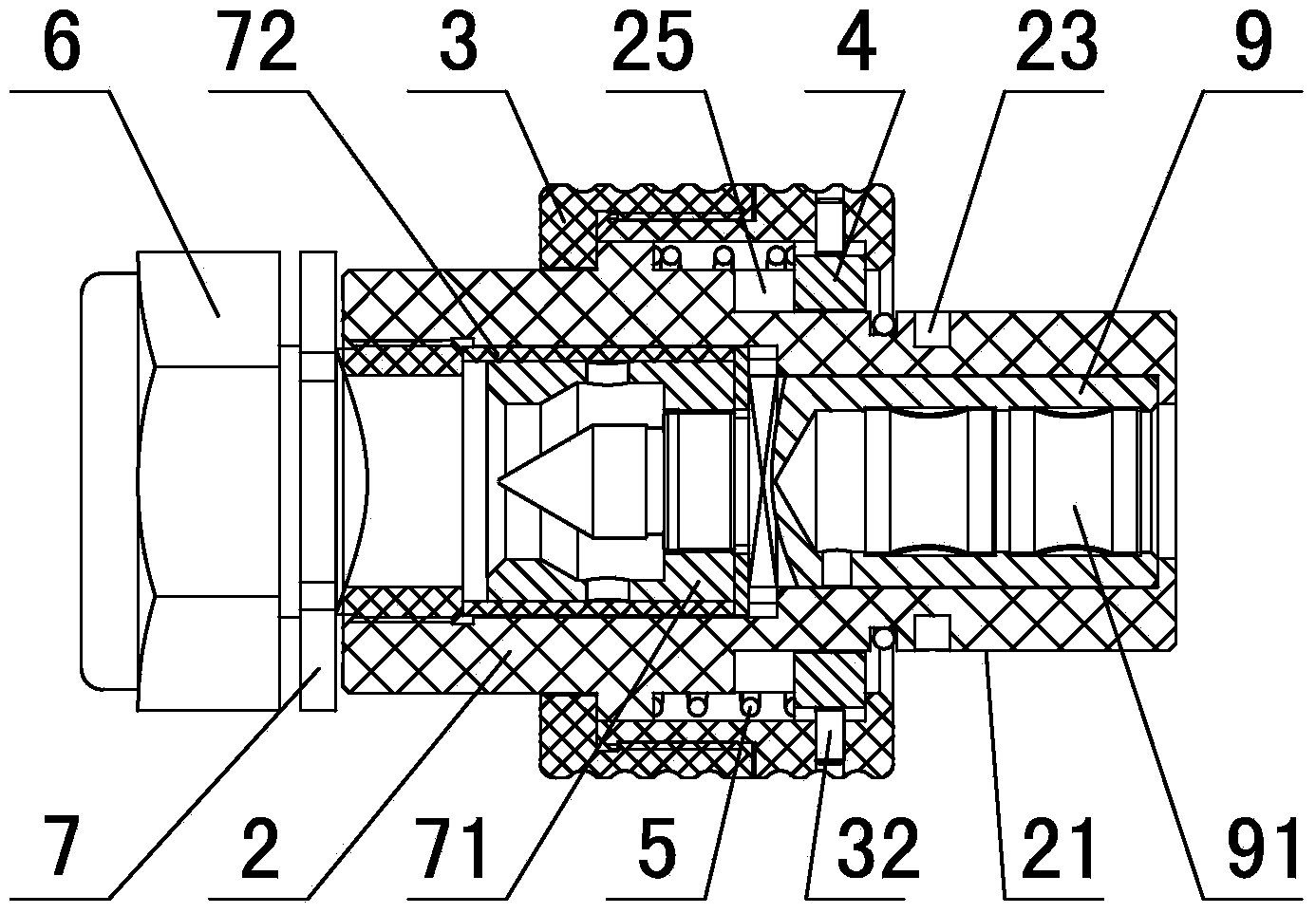

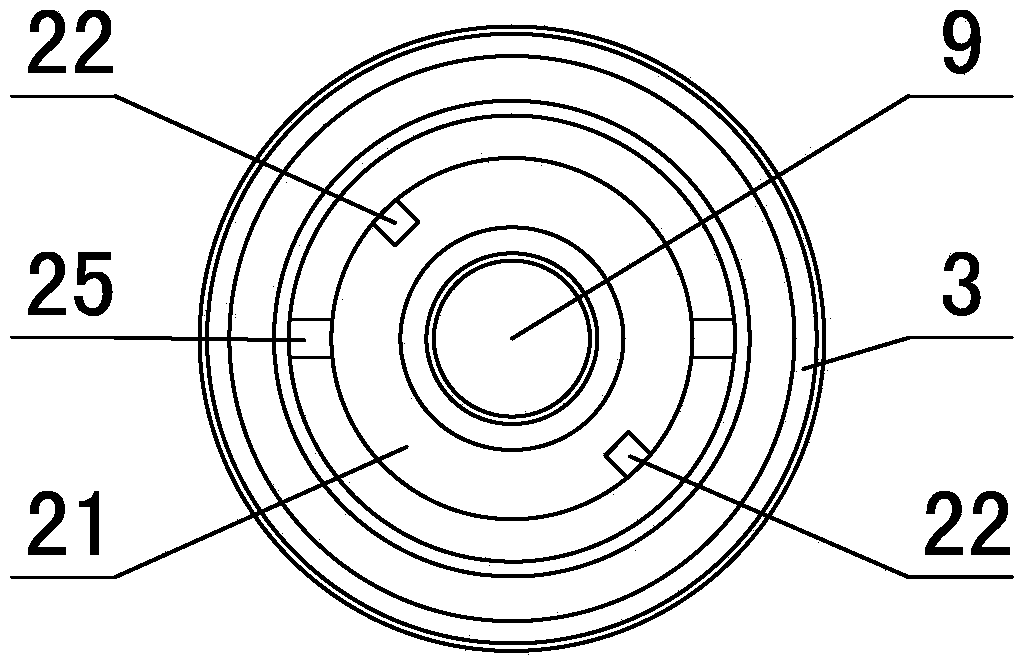

[0028] in such as figure 2 image 3 In the shown embodiment 1, a quick-locking and detaching connector plug, the insertion part 21 of the plug 2 is cylindrical, and an L-shaped groove is provided on the outer wall of the insertion part. The L There are 2 shaped grooves, which are evenly distributed on the outer wall of the plug socket, and the L-shaped grooves include axially arranged straight grooves 22 and circumferentially arranged transverse grooves 23 (see Figure 4 ), the central angle corresponding to the radial center line at both ends of the transverse groove is 45 degrees, one end of the straight groove communicates with the front end of the socket, the rear end of the socket is provided with a convex ring 24, and the socket is close to The position of the protruding ring is provided with a sealing groove, and a sealing ring is provided in the sealing groove; the protruding ring is provided with axially arranged positioning grooves 25, and there are two positioning...

Embodiment 2

[0032] A quick-locking, detachable connector socket, including a pluggable plug and a socket, the front part of the plug is a cylindrical insertion part, and the front part of the socket is a cylindrical front part Housing, the inner diameter of the front housing is adapted to the outer diameter of the socket part, and the outer wall of the socket part is provided with an L-shaped groove, and the L-shaped groove includes a straight groove arranged in the axial direction and a transverse groove arranged in the circumferential direction. slot, the straight slot communicates with the front end face of the socket, and the inner wall of the front housing is protruded with a staple matching the L-shaped slot; the front end of the front housing is provided with a keyway for insertion The rear end of the part is provided with a protruding ring, the outer diameter of the protruding ring is adapted to the outer diameter of the front housing, the front end of the protruding ring is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com