Spray collecting device

A collection device and collector technology, which is applied to the sampling device and other directions to achieve the effects of simple overall structure, good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

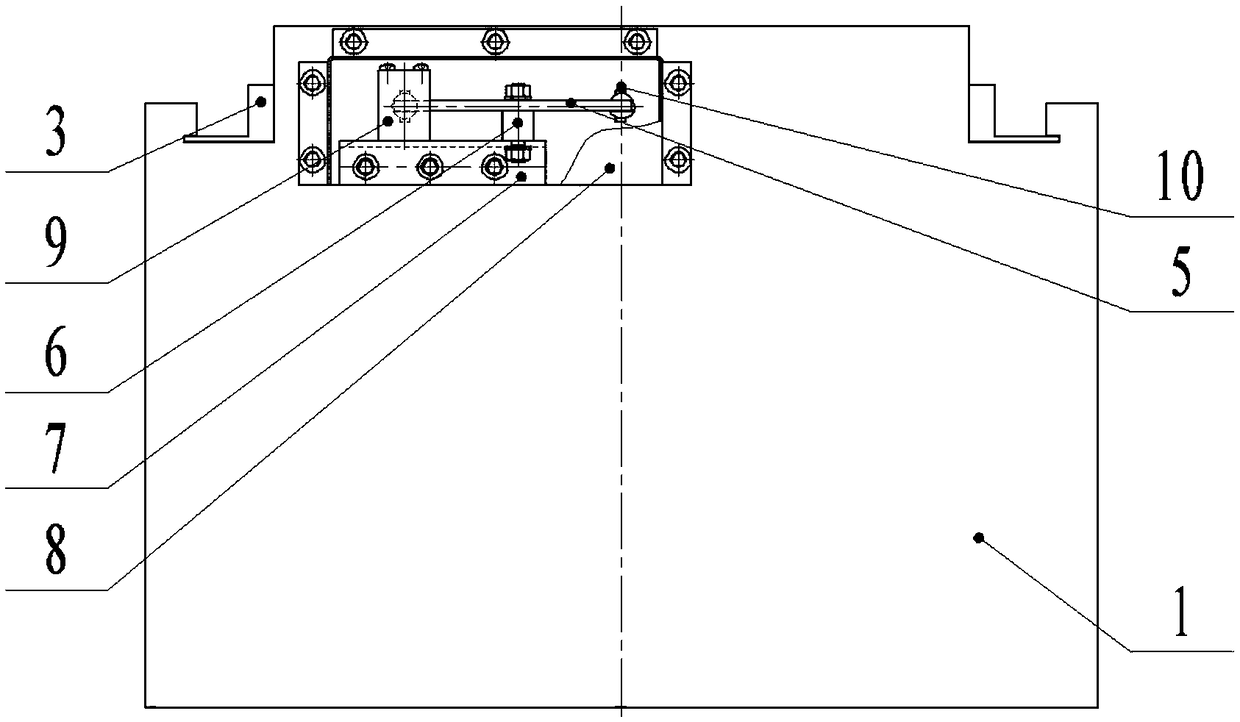

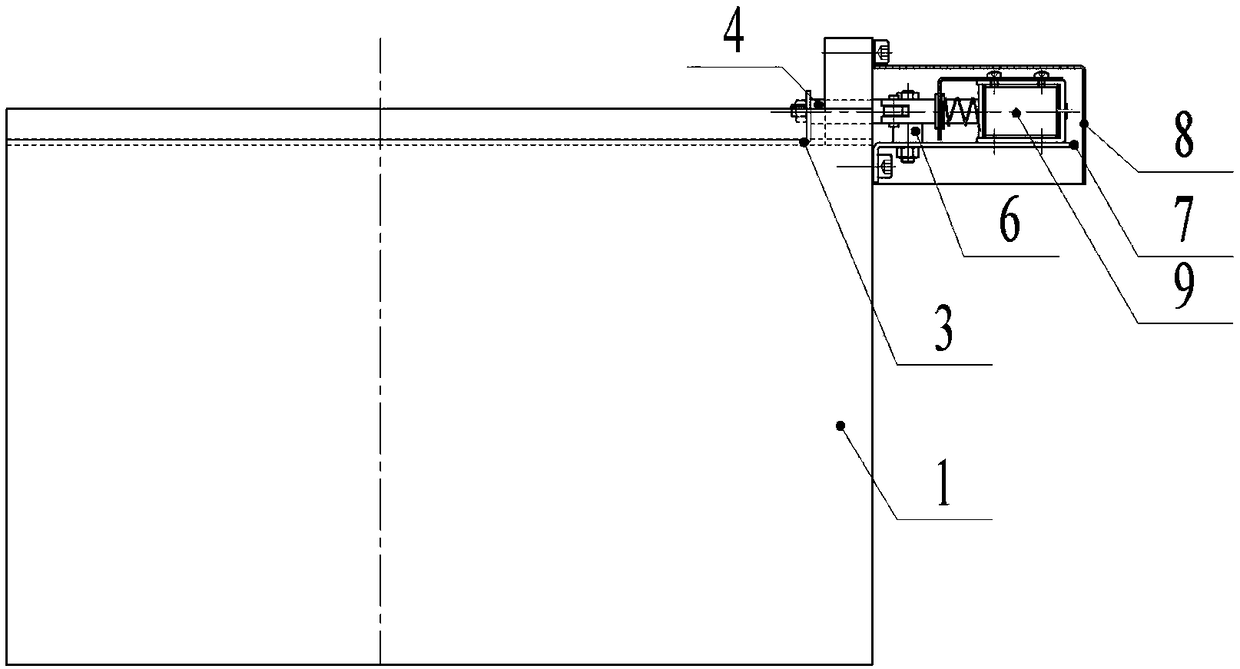

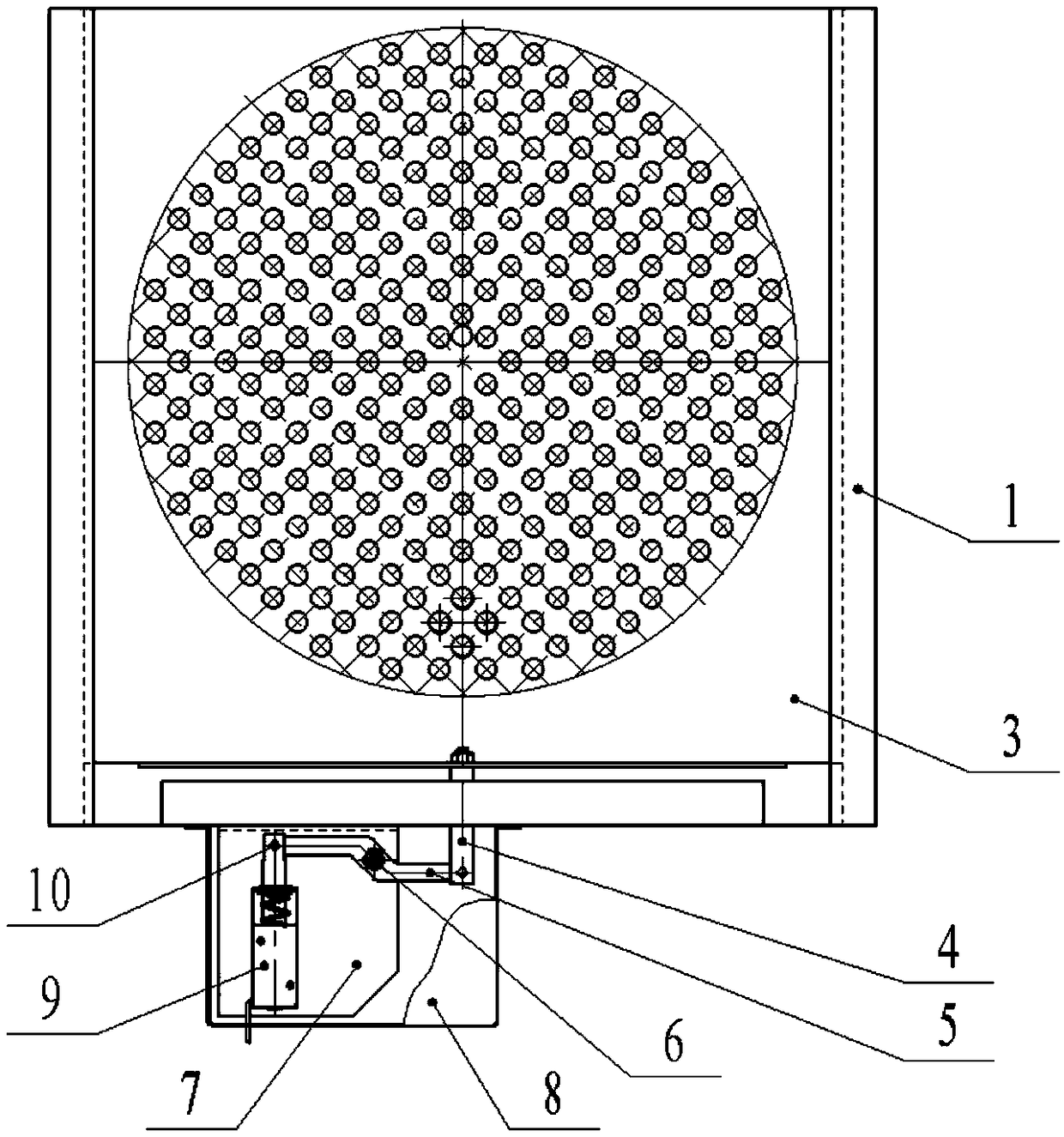

[0027] A spray collection device of the present invention, the main structure includes a collection chassis 1, a collector 2, a cover plate 3, a pull rod 4, a lever 5, a lever shaft 6, a waterproof box mounting plate 7, a waterproof box 8, an electromagnet 9, and a connecting pin 10.

[0028] like Figure 1 to Figure 3 As shown, the collection chassis 1 is the main part of the present invention, and is a left-right symmetrical square box. The collector 2 is installed inside the collection chassis 1 and can be taken out from the collection chassis 1 side. The card slot is located on the upper part of the collector 2, and fits with the collector 2, and can slide back and forth. Waterproof box mounting plate 7 is fixed on the side of collecting chassis 1, and electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com