Supplier terminal temperature monitoring system

A monitoring system and supplier’s technology, applied in the direction of temperature control using electric methods, can solve the problems of not having temperature, monitoring, and inability to monitor the operating status of supplier terminals in real time, so as to facilitate inspection and maintenance and improve convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

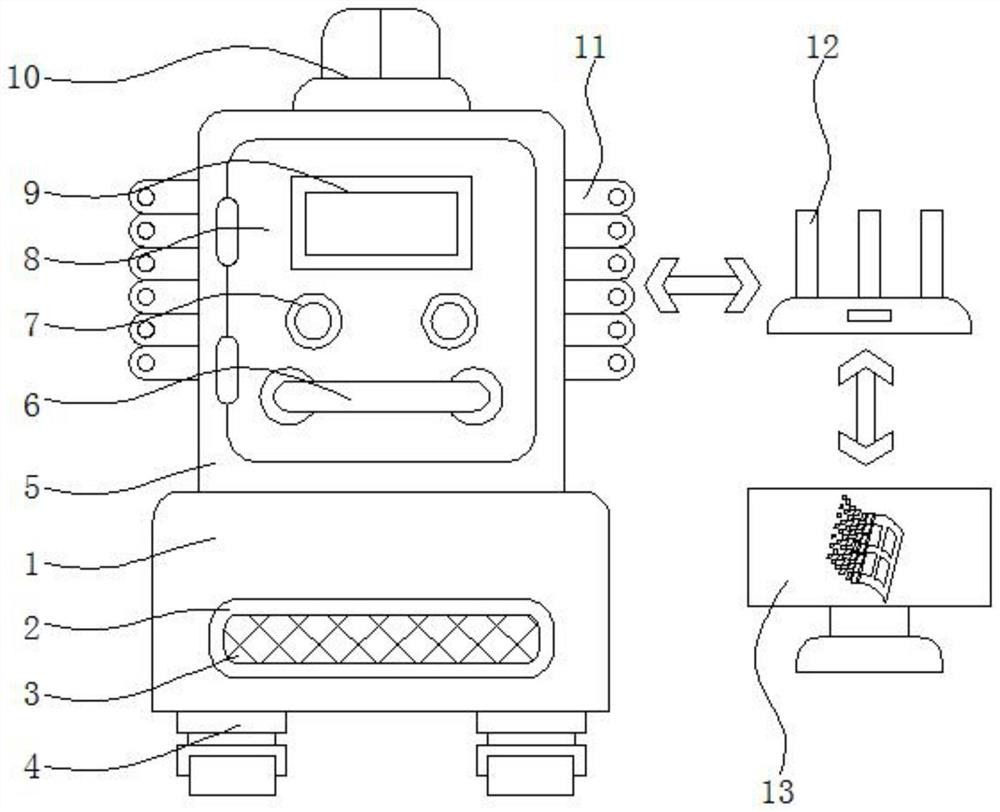

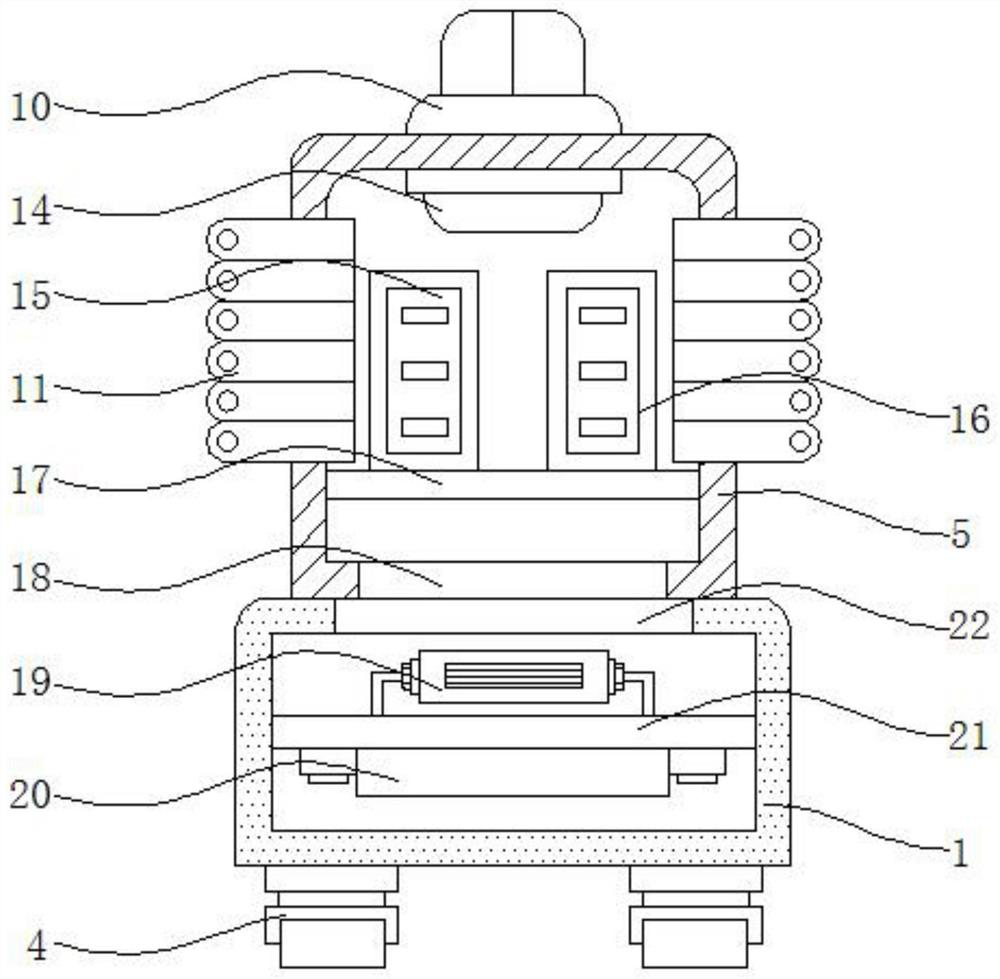

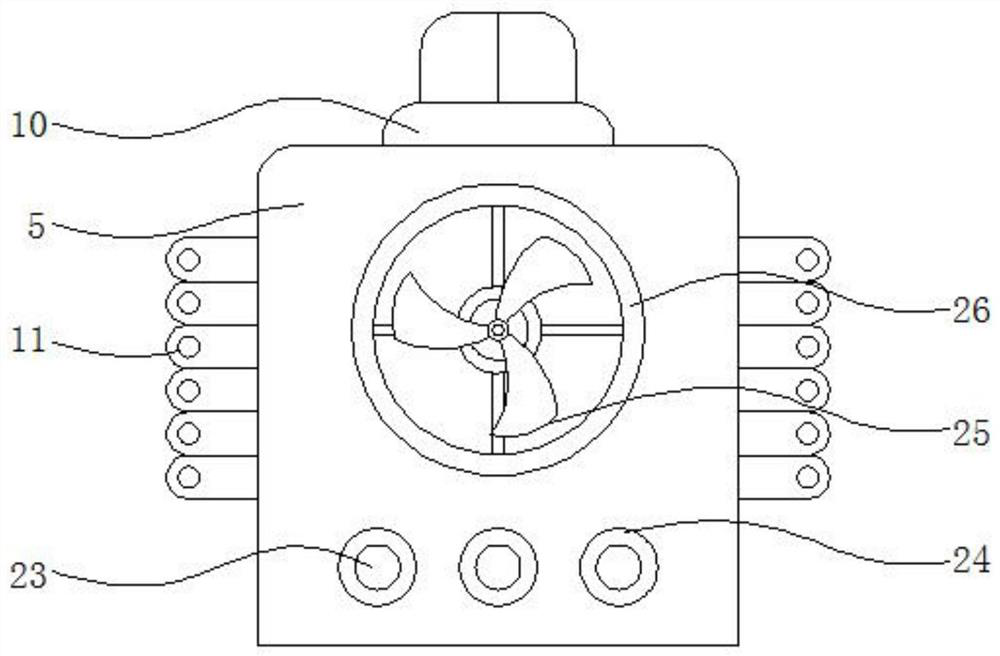

[0025] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,in, figure 1 A schematic structural diagram of a preferred embodiment of the supplier terminal temperature monitoring system provided by the present invention; figure 2 for figure 1 Cutaway view of the control box shown; image 3 for figure 1 Rear view of control box shown; Figure 4 for figure 1 A diagram of the vendor terminal temperature monitoring system shown. Supplier terminal temperature monitoring system, including support box 1, cooling vent 2, dust-proof net 3, moving wheel 4, control box 5, handle 6, relay 7, box door 8, display screen 9, alarm 10, heat sink 11 , wireless transmission module 12, monitoring terminal 13, lighting lamp 14, server 15, central processing unit 16, installation frame 17, first port 18, refrigerator 19, fan 20, fixed frame 21, second po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com