Multifunctional cable trench with high safety performance

A technology of safety performance and cable trench, applied in the field of multi-functional cable trench, can solve problems such as insufficient cable trench space, occupation of equipment foundation, difficulty in cable laying, etc., achieve clear and smooth cable direction, reduce project cost, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

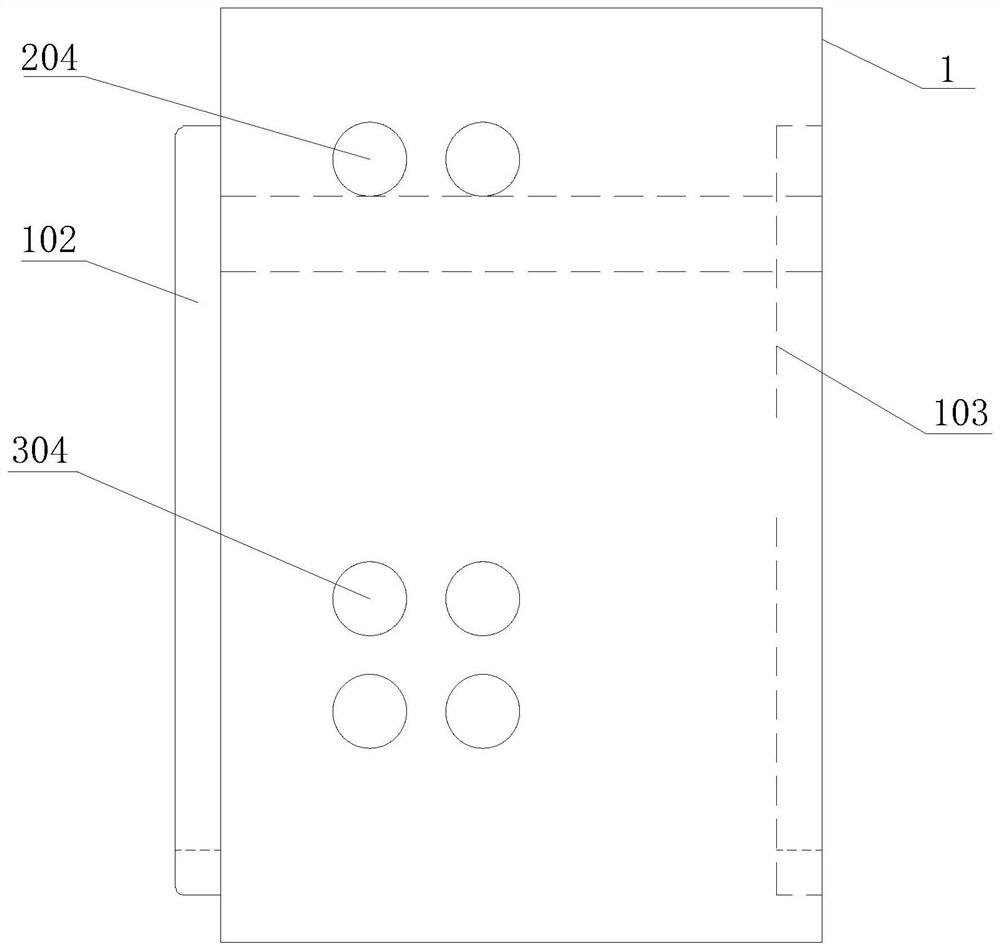

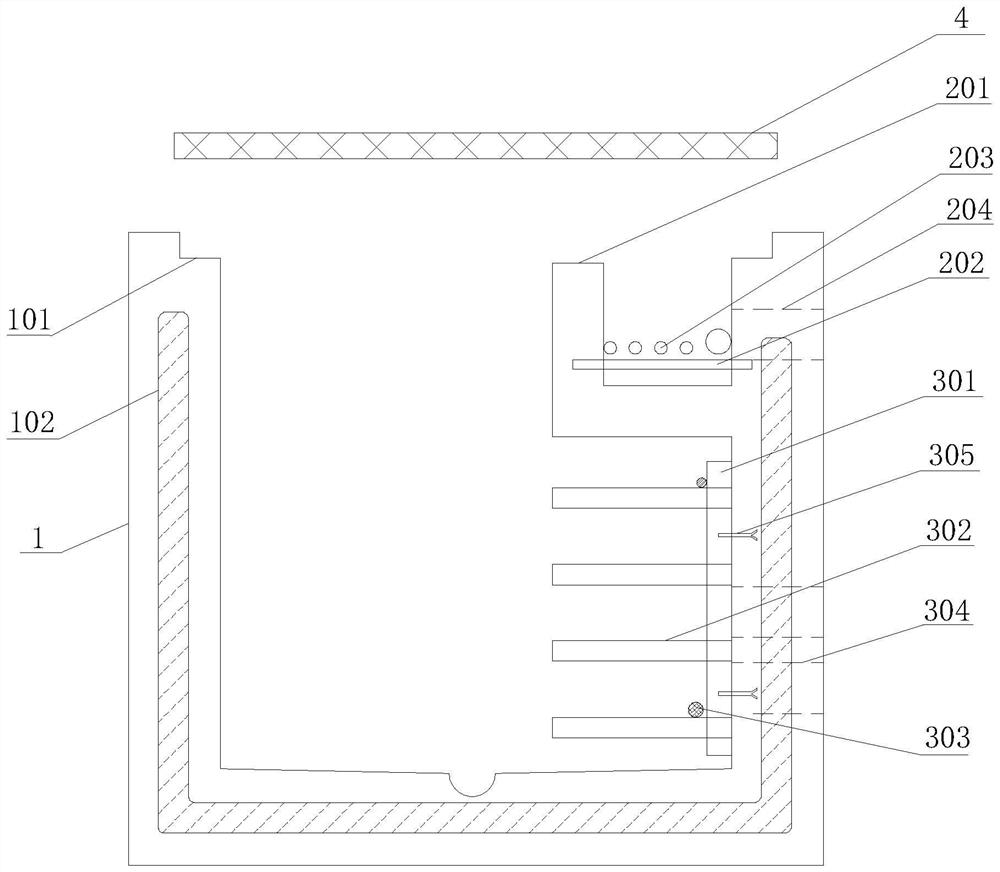

[0031] see Figure 1-2 , in the embodiment of the present invention: a multifunctional cable trench with high safety performance, including a cable trench body 1, the interior of the cable trench body 1 is divided into a power cable wiring area 2 and a control cable wiring area 3, and the power cable wiring area 2 and The control cable wiring area 3 is distributed up and down on the side wall of the cable trench body 1; wherein, according to construction requirements, a group of power cable wiring areas 2 and a group of control cables are distributed up and down on the side wall of the cable trench body 1 The wiring area 3 forms a single control cable single force cable trench structure.

[0032] In the above embodiment, the power cable wiring area 2 is composed of angle steel 201 and round steel 202. The angle steel 201 is integrally embedded above the inner wall of the cable trench body 1, and the opening is upward. The bottom of the angle steel 201 and the cable trench body...

Embodiment 2

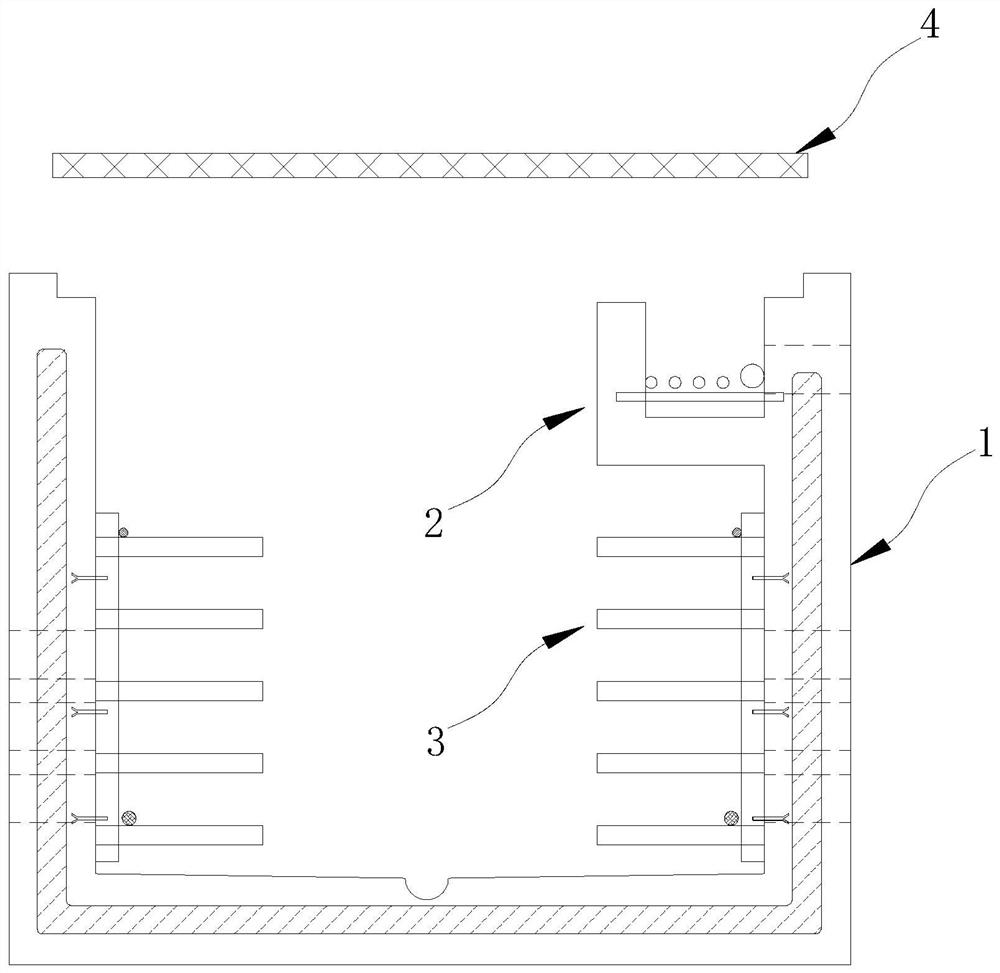

[0038] see image 3, in the embodiment of the present invention: a multifunctional cable trench with high safety performance, including a cable trench body 1, the interior of the cable trench body 1 is divided into a power cable wiring area 2 and a control cable wiring area 3, and the power cable wiring area 2 and The control cable wiring area 3 is distributed up and down on the side wall of the cable trench body 1; wherein, according to construction requirements, a group of power cable wiring areas 2 and a group of control cables are distributed up and down on the side wall of the cable trench body 1 Wiring area 3, and a set of control cable wiring area 3 is provided on the other side wall of the cable trench body 1 to form a cable trench structure with double control cables and single force cables.

[0039] In the above embodiment, the power cable wiring area 2 is composed of angle steel 201 and round steel 202. The angle steel 201 is integrally embedded above the inner wall...

Embodiment 3

[0045] see Figure 4 , in the embodiment of the present invention: a multifunctional cable trench with high safety performance, including a cable trench body 1, the interior of the cable trench body 1 is divided into a power cable wiring area 2 and a control cable wiring area 3, and the power cable wiring area 2 and The control cable wiring area 3 is distributed up and down on the side wall of the cable trench body 1; wherein, according to construction requirements, a group of power cable wiring areas 2 and a group of control cable wiring areas are distributed up and down on both sides of the cable trench body 1. The cable routing area 3 forms a cable trench structure with dual control cables and dual force cables.

[0046] In the above embodiment, the power cable wiring area 2 is composed of angle steel 201 and round steel 202. The angle steel 201 is integrally embedded above the inner wall of the cable trench body 1, and the opening is upward. The bottom of the angle steel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com