Tree pit planting soil tamping device and tamping method

A technology for tree holes and utensils, which is applied in the field of tree hole planting soil tamping equipment and tamping. It can solve the problems of long time consumption, failure to meet quality requirements, missing tamping, etc., and achieve the effect of avoiding extrusion and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

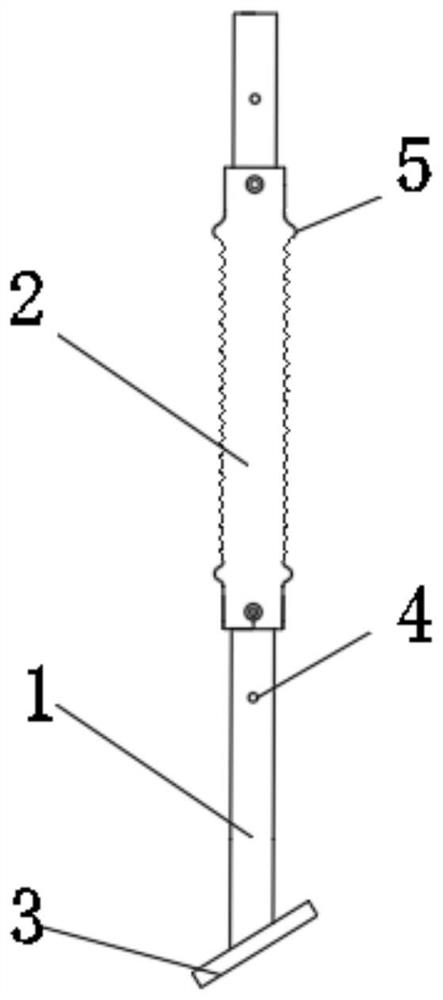

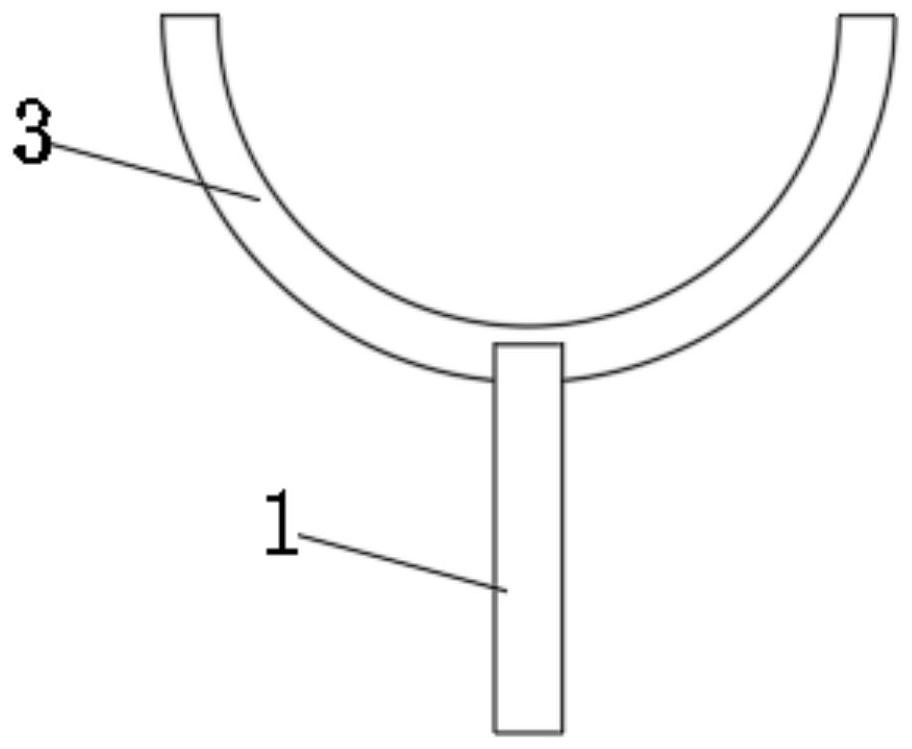

[0026] Such as figure 1 As shown, in this embodiment, a tree hole planting soil tamping device includes a support rod 1 and a tamping plate 3 arranged at one end of the support rod 1 , and the tamping plate 3 is arranged obliquely relative to the length direction of the support rod 1 .

[0027] During construction, the staff use the tamping plate 3 to tamp the bottom of the planting hole, then lift the trees into the planting hole, backfill a layer of soil in the planting hole, and use the tamping plate 3 to tamp the backfill soil, and repeat the operation many times to make the backfill soil layer by layer Layers are backfilled and compacted until the planting hole is filled with soil and the filled soil is compacted.

[0028] Since the tamping plate 3 is arranged obliquely with respect to the length direction of the support rod 1, the staff can apply pressure to the support rod 1 at a position far away from the planting hole, which is beneficial to the operation of the staff...

Embodiment 2

[0030] Such as Figure 4 As shown, on the basis of the above embodiments, in this embodiment, the support rod 1 is provided with a non-slip sleeve 2 made of rubber. Utilize the anti-slip cover 2 to increase the frictional force at the staff's hand-hold to avoid slipping.

[0031] The anti-slip cover 2 is provided with anti-slip patterns, and the two ends of the anti-slip cover 2 are provided with limit rings 5. When the limit ring 5 is used to limit the effective position of the hand-holding range when the staff holds the support rod 1, it is avoided during use. Hand slipping or improper application of force causes the staff's palm to separate from the anti-slip sleeve 2, thereby increasing safety risks or affecting construction operations.

[0032] In this embodiment, an adjustment sleeve 8 is slidably disposed on the support rod 1 , and the anti-slip sleeve 2 is disposed on the adjustment sleeve 8 . By moving the adjusting sleeve 8, the position of the anti-slip sleeve 2 a...

Embodiment 3

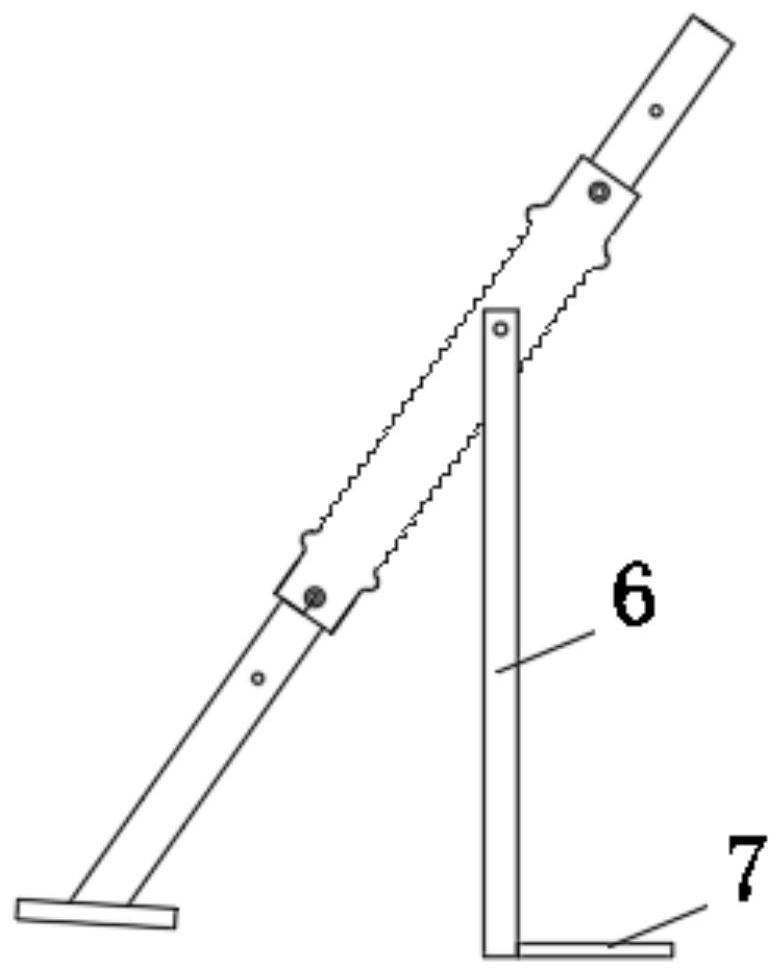

[0035] Such as figure 2 As shown, on the basis of the above embodiments, in this embodiment, the adjustment sleeve is provided with a bracket 6 supported on the ground, and the adjustment sleeve is hinged to the bracket 6 . The bracket 6 is supported on the ground so that the support rod 1 forms a lever structure, which can improve the stability of the support rod 1 during use, thereby making it easier for the staff to apply force and simplifying the operation.

[0036] In this embodiment, the bottom of the bracket 6 is provided with a pedal 7 . The stability of the bracket 6 can be improved by stepping on the pedal 7, and the inconvenience of use caused by the random movement or shaking of the bracket 6 can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com