filter device

A filter device and filter unit technology, which is applied in the direction of dispersed particle filtration, separation method, and dispersed particle separation, etc. It can solve the problems of being unable to judge the filter unit, not knowing when to replace the filter unit, and being unable to prevent and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

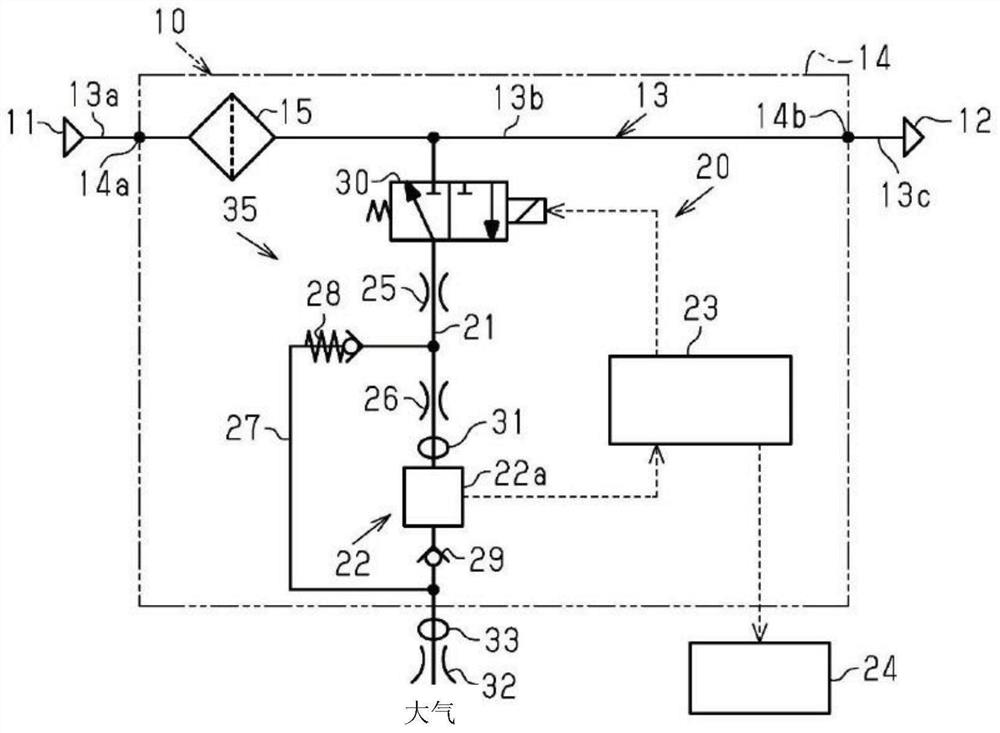

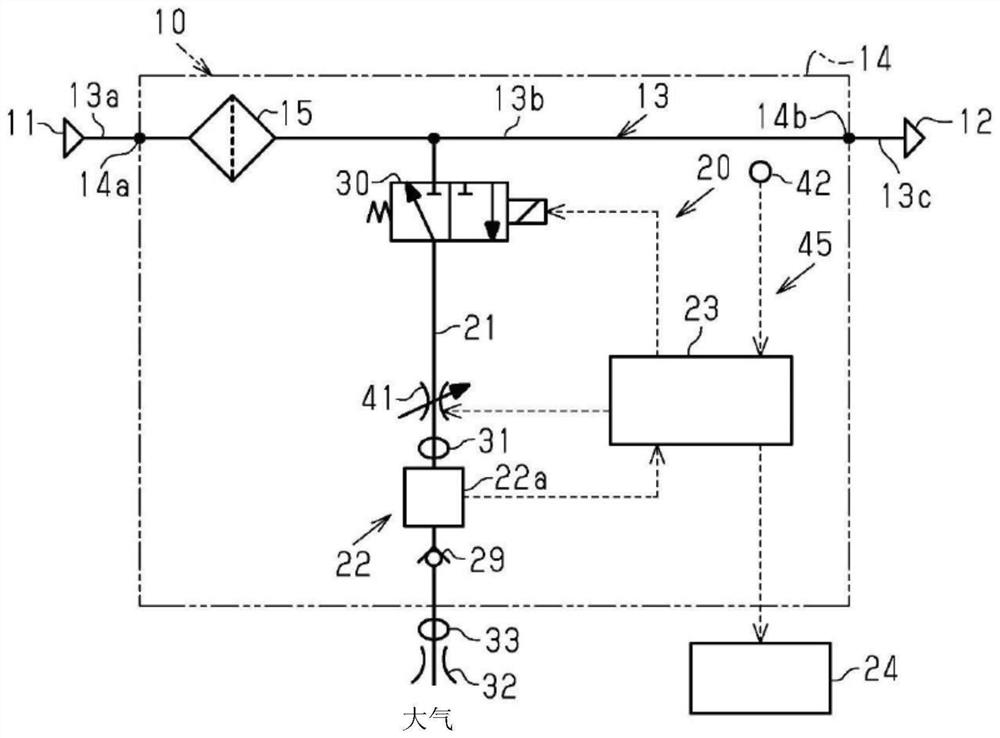

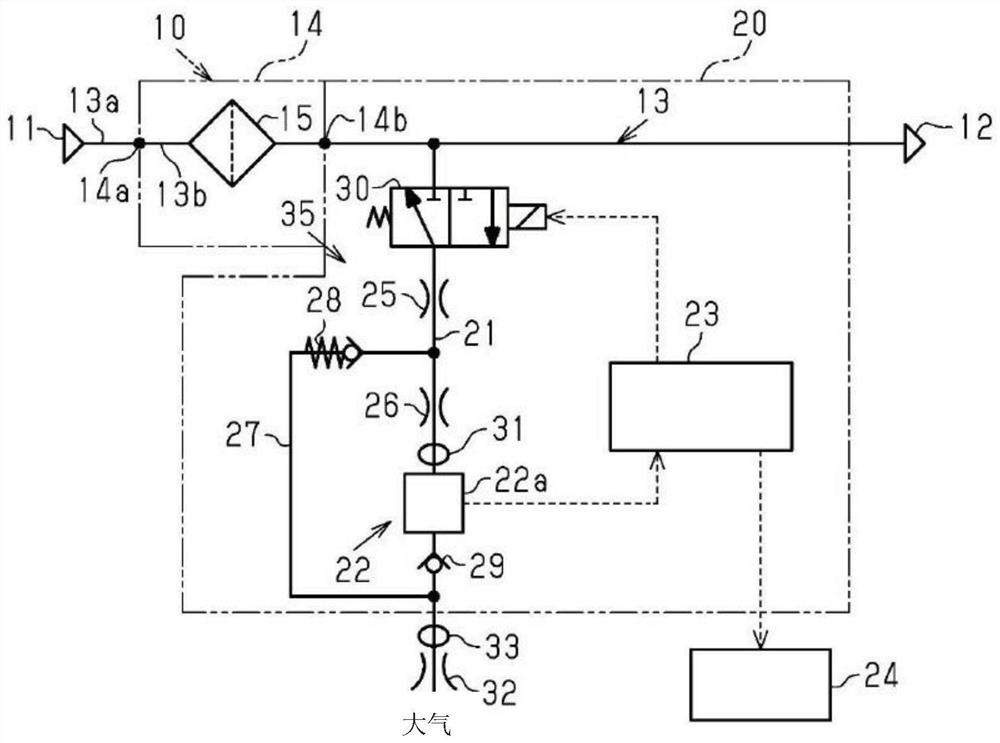

[0020] Below, according to figure 1 The first embodiment of the actual filtering device will be described.

[0021] Such as figure 1 As shown, the filter device 10 is provided in a supply flow path 13 that supplies compressed air from an air supply source 11 to a pneumatic machine 12 . The pneumatic machine 12 is driven by compressed air supplied from the air supply source 11 through the supply flow path 13 . The supply channel 13 is constituted by, for example, piping or the like.

[0022] The filter device 10 has a body 14 . The main body 14 has a supply hole 14a and a discharge hole 14b. The supply channel 13 has a first channel 13a, a second channel 13b, and a third channel 13c. The first flow path 13 a connects the air supply source 11 and the supply hole 14 a outside the main body 14 . The second flow path 13b connects the supply hole 14a and the discharge hole 14b inside the main body 14 . The third flow path 13c connects the discharge hole 14b and the pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com