Molten metal fluid temperature polymorphic online detection method and system

A technology for molten metal and fluid temperature, which is applied in the field of multi-state online detection method and system for molten metal fluid temperature, and can solve problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

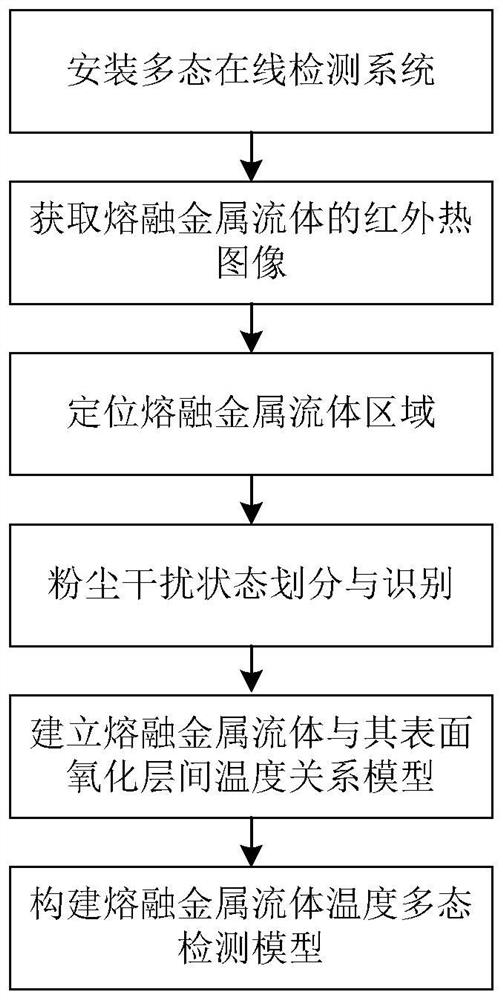

[0047] The multi-state online detection method for molten metal fluid temperature provided by Embodiment 1 of the present invention includes:

[0048] Step S101, acquiring the infrared thermal image of the molten metal fluid, and extracting the molten metal fluid area in the infrared thermal image of the molten metal fluid;

[0049] Step S102, dividing the dust interference state of the smelting site, and establishing a deep network model for identifying different interference states of the dust;

[0050] Step S103, based on the deep network model, using the infrared radiation temperature measurement mechanism to construct a multi-state detection model for the temperature of the oxide layer on the surface of the molten metal fluid under different dust interference states;

[0051] Step S104, according to the polymorphic detection model of the temperature of the molten metal fluid surface oxide layer, using the heat transfer relationship between the molten metal fluid and its s...

Embodiment 2

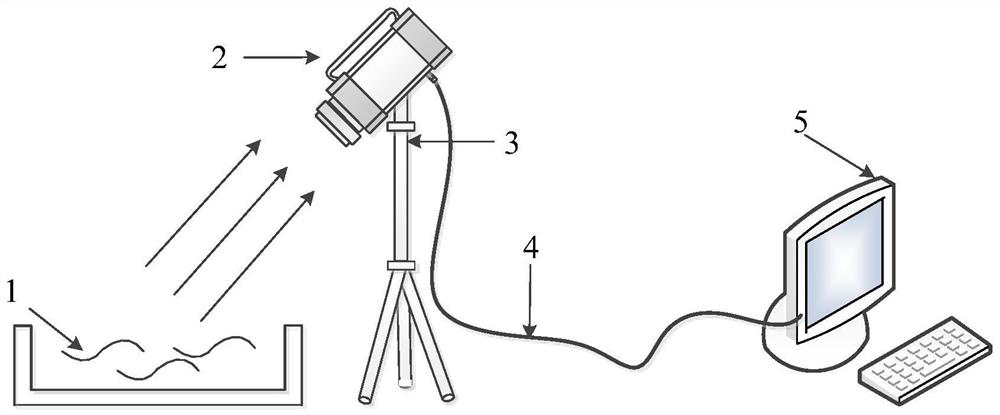

[0055] refer to figure 1 , figure 1 It is a schematic diagram of the installation of the molten metal fluid temperature multi-state online detection system according to the embodiment of the present invention. The system includes a molten metal fluid 1, a multi-state detection device 2, a bracket 3, an integrated cable 4, and a computer 5. figure 2 It is a flow chart of the embodiment of the present invention to realize the multi-state online detection method of molten metal fluid temperature, including the following steps:

[0056] (1) Use the multi-state detection system to obtain the infrared thermal image containing the molten metal fluid area, and automatically locate the molten metal fluid area;

[0057] (2) Divide the dust interference state of the smelting site, and establish a deep network model that takes the infrared thermal image of molten metal fluid as input to intelligently identify different interference states of dust;

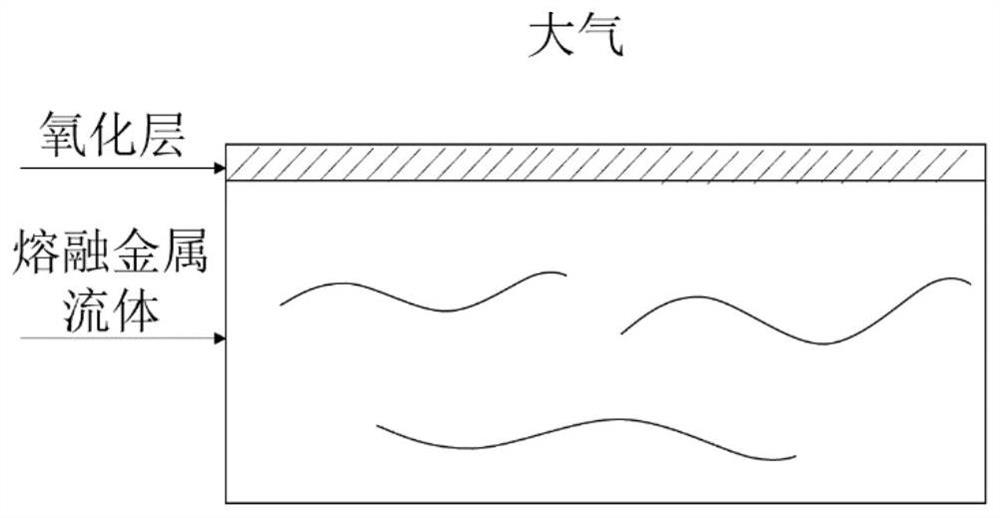

[0058] (3) Considering the influence...

Embodiment 3

[0141] Present embodiment three takes certain ironworks 1050m 3 The blast furnace is used as a test platform, and the invented multi-state detection method and system for molten metal fluid temperature are applied to the online detection of molten iron flow temperature at the No. 1 taphole skimmer of the blast furnace. The multi-state detection system is installed behind the skimmer to obtain infrared thermal images of the molten iron flow after skimming. Figure 4 Shown is the temperature measurement result of the molten iron of the present invention in one tapping furnace. In order to illustrate the temperature measurement effect of the present invention, the temperature measurement results of the fast thermocouples at the same position and at the same time are used as reference values to compare and analyze the accuracy of the multi-state temperature measurement results. Depend on Figure 4 As can be seen, the temperature measurement result of molten iron of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com