Intelligent deflection adjusting device applied to circular-pipe-belt conveyor

A conveyor and torque adjustment technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of a large number of detection components, unsatisfactory actual results, and low deviation correction ability, and achieve long service life, continuous and effective. The effect of strong detection and correction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

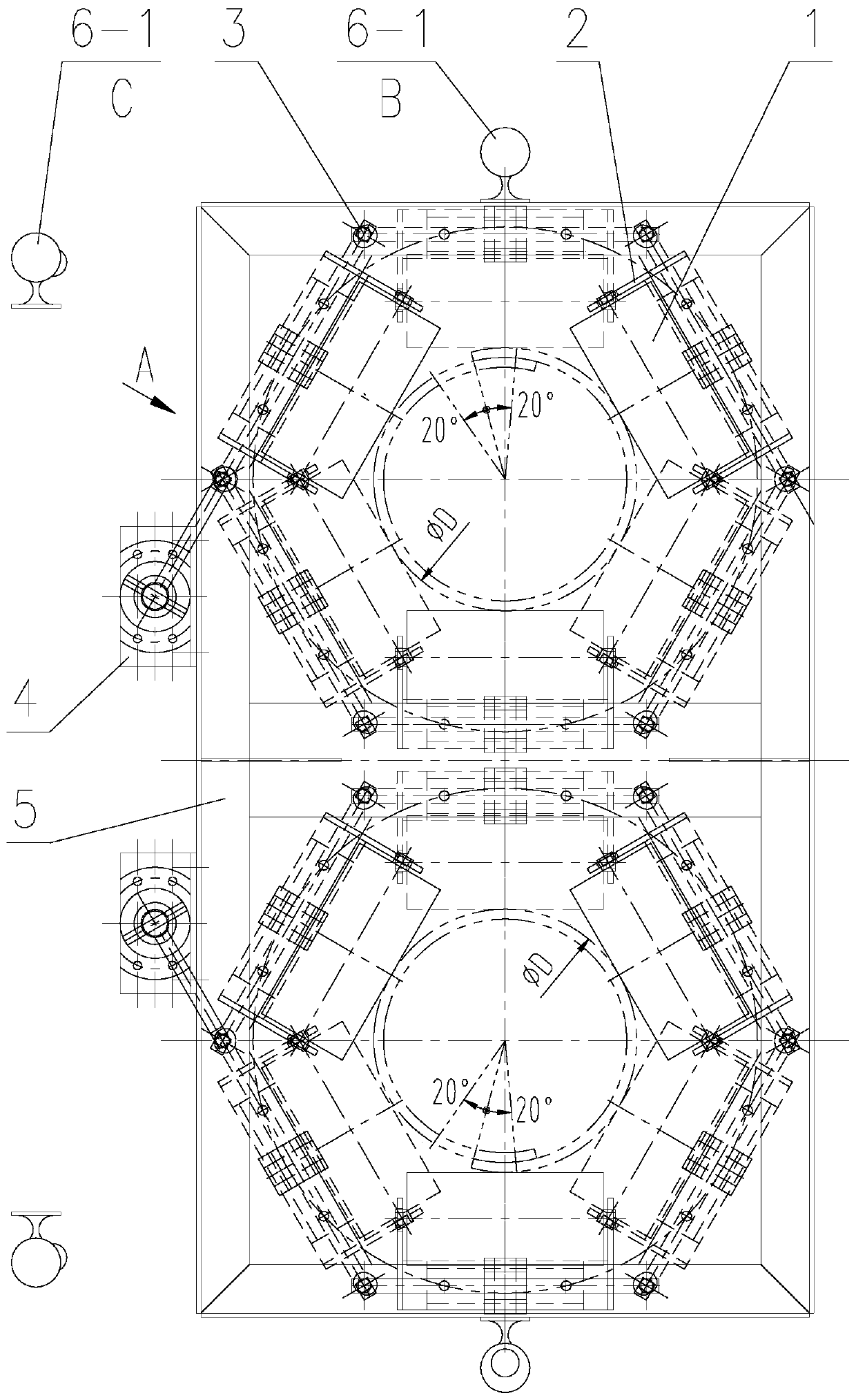

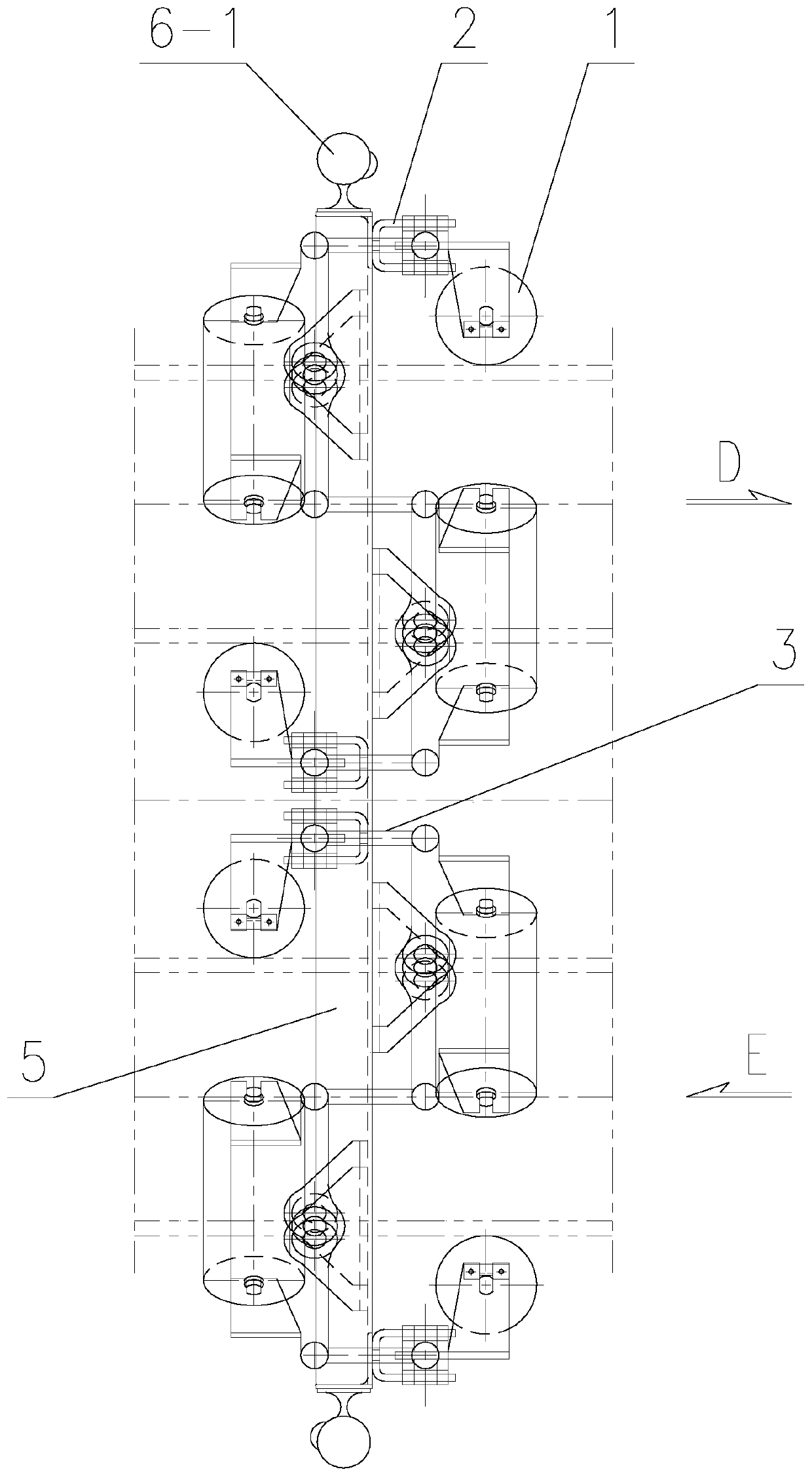

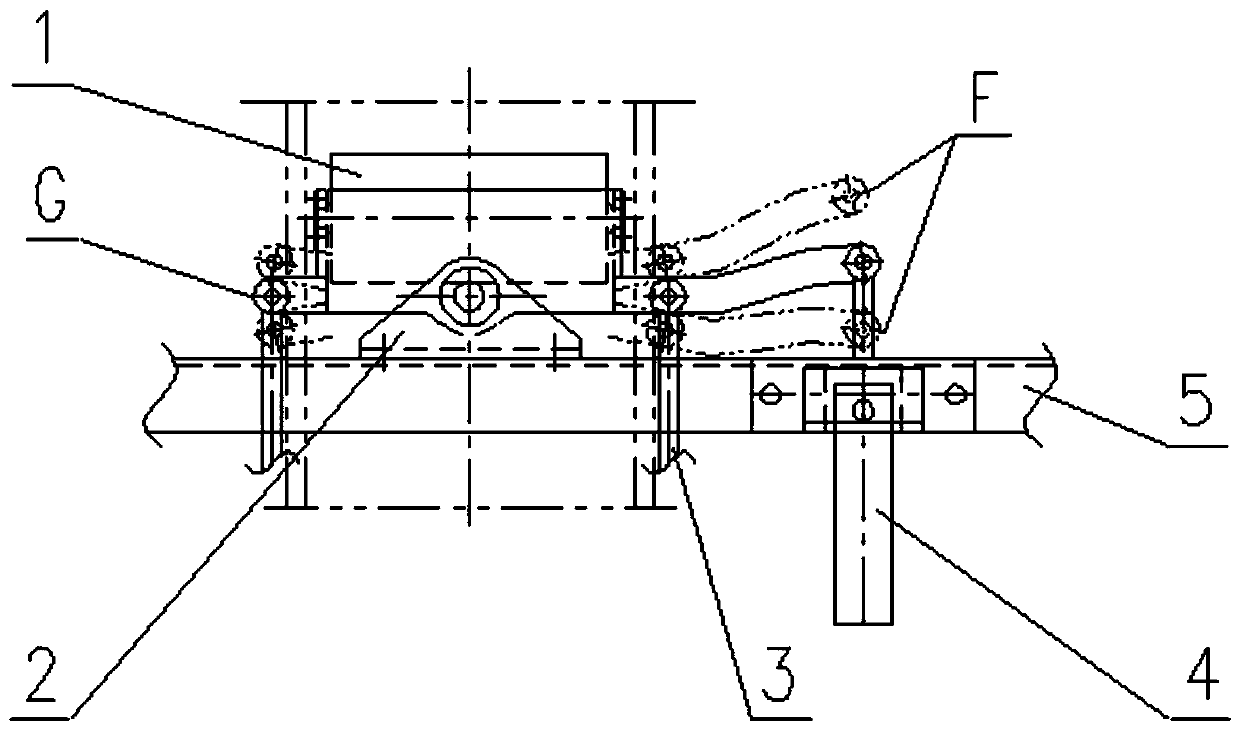

[0019] Referring to the accompanying drawings, an intelligent torsion adjustment device applied to a round pipe belt conveyor, including idler 1, execution part 2, connecting rod 3, power part 4, frame 5, intelligent control part 6, and execution part 2 arranged in a staggered manner On both sides of the frame 5 and connected with each other by the connecting rod 3, the idler 1 is installed on the bracket 2-1 of the execution part 2; the power part 4 is installed on the outside of the frame 5, and the push rod of the electro-hydraulic push rod 4-1 It is connected with the bracket 2-1 of the execution part 2; the camera 6-1 of the intelligent control part 6 is installed on the frame 5; 2-3, install the swingable bracket 2-1 on the support base 2-2 and fix it with the connecting pin 2-3; the power part 4 includes the electro-hydraulic push rod 4-1, the base 4-2, and the Install electro-hydraulic push rod 4-1 on -2; intelligent control part 6 includes camera 6-1, data transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com