Preparation method of colorful coating, colorful coating and lamp fitting

A kind of colorful and coating technology, which is applied in the direction of coating, multi-color effect coating, device for coating liquid on the surface, etc., can solve the problems that cannot meet the actual needs, the color is single, and the color of the hardware workpiece is monotonous, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

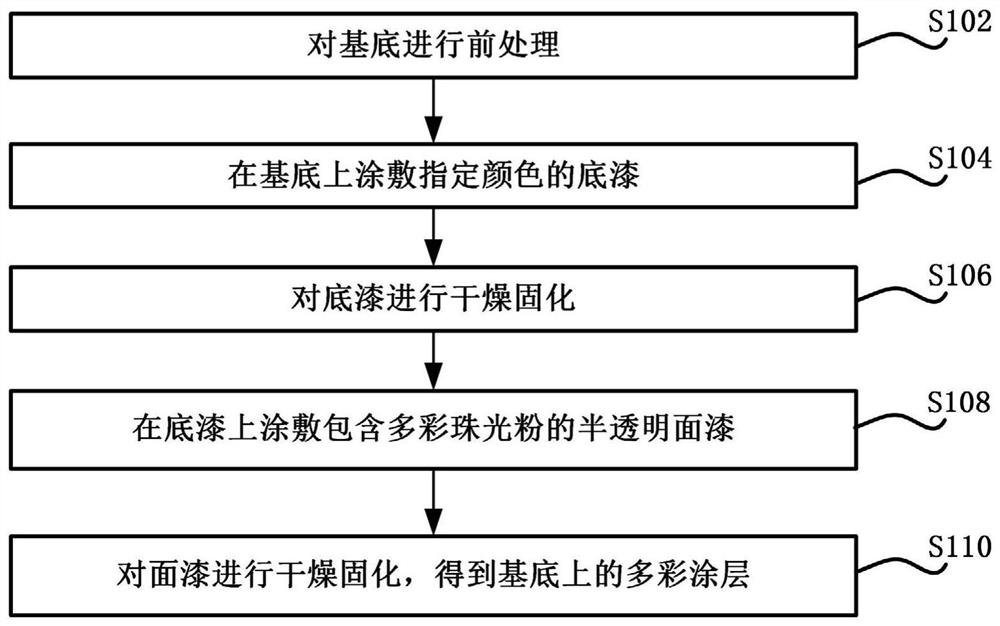

[0033] figure 1 It is a flow chart of the preparation method of the colorful coating according to one embodiment of the present invention. see figure 1 , the preparation method of the colorful coating may include the following steps S102 to S110.

[0034] Step S102: performing pretreatment on the substrate.

[0035] Step S104: Apply a primer of a specified color on the base.

[0036] Step S106: drying and curing the primer.

[0037] Step S108: Coating a translucent topcoat containing colorful pearlescent powder on the primer.

[0038] Step S110: drying and curing the top coat to obtain a colorful coating on the base.

[0039] In the preparation method of the colorful coating of the present embodiment, by coating the primer of designated color on the substrate, and coating the translucent topcoat that comprises multicolored pearl powder on the primer of drying and curing, and carrying out to the topcoat After drying and curing, a colorful coating on the substrate can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com