A deburring device and deburring method for cast steel joints

A cast steel joint and deburring technology, which is applied to machine tools suitable for grinding the edge of workpieces, parts of grinding machine tools, manufacturing tools, etc., can solve the problem of burrs or incomplete disconnection of burrs, blockage of inner holes, and influence on joints. Use and other issues to achieve the effect of improving work efficiency, avoiding sliding, and reducing mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

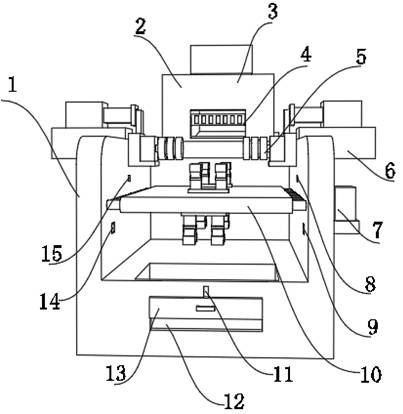

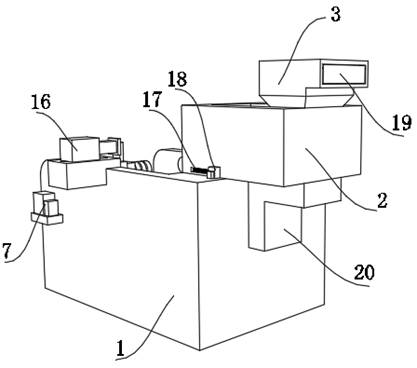

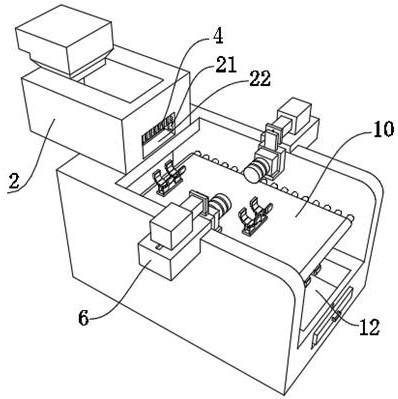

[0042] A deburring device for cast steel joints such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, including the body 1, the top outer wall of the body 1 is fixed with two fixing seats 6 by bolts, and the top outer walls of the two fixing seats 6 are provided with electric chute 23, and the inner walls of the two electric chute 23 pass through The slider is slidably connected with a hydraulic cylinder 16, and the extension ends of the two hydraulic cylinders 16 are fixed with a partition plate 26 by bolts, and the outer walls of one side of the two partition plates 26 are provided with a second electric slide rail 27. The inner walls of the two electric slide rails 27 are all slidably connected with connecting plates 30 by sliders, and the bottom outer walls of the two connecting plates 30 are fixed with a placing plate 29 by bolts. The placing plate 29 is an L-shaped structure, and the top of the two placing plates 29 The outer wall is fixed with a third moto...

Embodiment 2

[0053] A deburring method for the deburring device described in embodiment 1, such as Figure 9 shown, including the following steps:

[0054] S1: Feeding: put the joint into the feed box 3, enter the storage box 2 and wait for conveying and processing;

[0055]S2: Conveying and fixing: the joint falls onto the two electric expansion plates 35, and the cylinder 36 is adjusted so that the two clamping blocks 34 are driven by the electric expansion plate 35 to clamp the joint;

[0056] S3: grinding: start the third motor 28, and deburr the joint by adjusting the starting hydraulic cylinder 16 and the second electric slide rail 27;

[0057] S4: conveying and discharging: after the burrs are removed, start the cylinder 36 to make the treated joints break away from the clamping block 34;

[0058] S5: collect materials: collect materials in the discharge trough 12, just take it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com