A panda-shaped microstructure optical fiber filled with silver wire and an elliptical core and its preparation method

A microstructure optical fiber, elliptical technology, applied in the direction of cladding optical fiber, glass manufacturing equipment, glass fiber products, etc., can solve the problems of uneven metal and poor effect, and achieve the effect of suppressing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

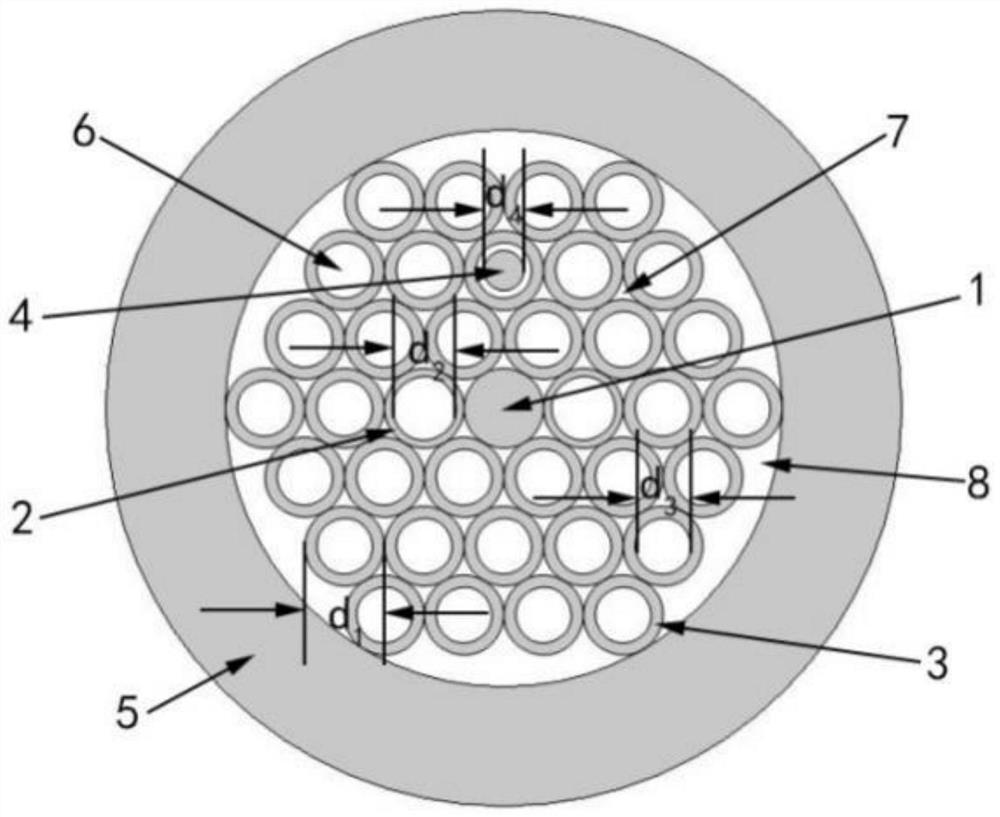

[0058] (1) Use quartz glass tubes with different inner diameters to draw capillaries: specifically, glass tubes with an outer diameter of 20 mm, an inner diameter of 14 mm, and a glass tube with an outer diameter of 16 mm and an inner diameter of 12 mm are drawn into capillaries with an outer diameter of 2 mm, and the inner diameters are respectively 1.4 mm. And the capillary of 1.5mm, wherein, the outer diameter is 2mm, inner diameter is the quartz glass capillary 3 of smaller inner diameter, and the outer diameter is 2mm, inner diameter is the quartz glass capillary 2 of larger inner diameter. A silver wire 4 with a diameter of 1.0 mm and a purity of 99.9% is stuffed into a capillary with an inner diameter of 1.4 mm, and one end of the silver-filled capillary is melted to death with an oxyhydrogen flame. The capillary tubes with an inner diameter of 1.4 mm are stacked into a hexagonal shape by using the ladder-type stacking method, and then the corresponding capillary tubes w...

Embodiment 2

[0068] A method for preparing a panda-shaped microstructure optical fiber filled with silver wires and an elliptical core is the same as that in Embodiment 1.

[0069] The parameter fitting curves of temperature and air pressure when preparing silver-filled elliptical-core panda-shaped microstructured optical fiber are as follows: Figure 8 As shown, when the fiber diameter is thicker, the temperature is higher, and the air holes in the cladding have been collapsed into a solid. At the beginning of wire drawing, the air holes in the cladding are mainly reduced by lowering the furnace temperature. Since the filaments are thicker at the beginning, the temperature drop is relatively large. When the furnace temperature drops to 1760°C, the pores in the cladding basically appear. At this time, a pressure holding device is added and the pressure threshold is gradually increased. As the filament becomes thinner, the optical fiber will become brittle. In order to prevent the optical ...

Embodiment 3

[0071] A method for preparing a panda-shaped microstructure optical fiber filled with silver wires and an elliptical core is the same as that in Embodiment 1.

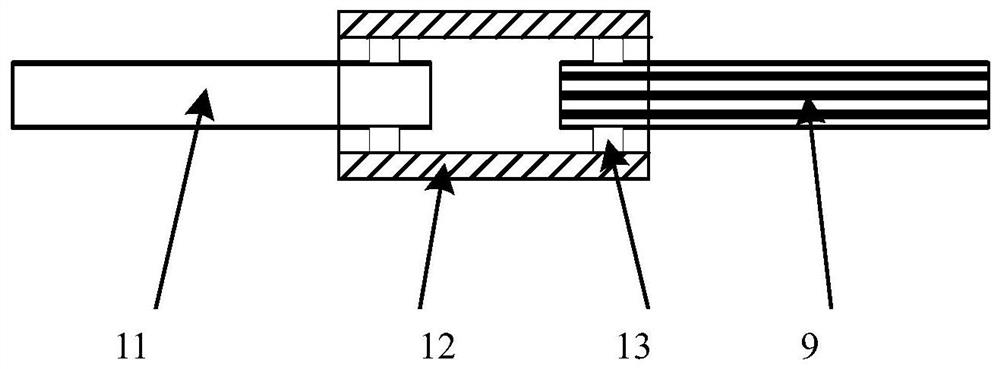

[0072] A section of multimode optical fiber is fused to each end of this panda-shaped microstructure fiber filled with silver thread, and the two ends of the optical fiber are respectively connected to a broadband light source and a spectrometer. The schematic diagram of the experimental system is as follows: Figure 10 As shown in the figure, 1 is a silver-filled elliptical core panda-shaped microstructured optical fiber; 2 is a multimode optical fiber. The light emitted by the broadband light source passes through the panda-shaped silver-filled microstructured optical fiber and then enters the spectrometer. The spectrometer displays the transmission spectrum. The transmission spectrum is as follows: Figure 11 shown. It can be seen from the transmission spectrum that the transmission spectrum power of the panda-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap