Coating for spraying iron art guardrail and preparation method thereof

A technology for guardrails and coatings, applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of cracks and poor adhesion in film formation, and achieve good aging resistance, strong film formation and water resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

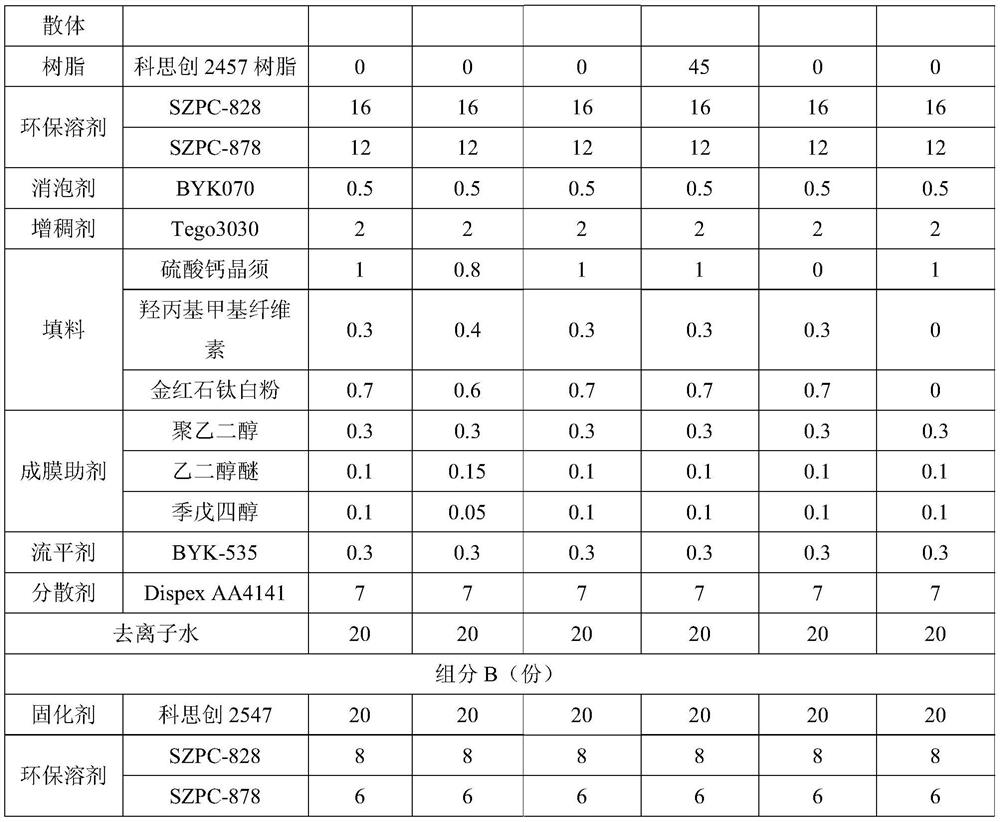

[0038] A kind of coating for wrought iron guardrail spraying, coating comprises component A and component B, and the weight ratio of component A and component B is 7:1, and each raw material consumption of component A, component B is as shown in table 1 below,

[0039] The preparation method of the coating comprises the following steps: Preparation of Component A: Pour 15 parts of deionized water into a grinding tank, add 0.5 parts of defoamer, 0.3 parts of leveling agent, 7 parts of dispersant, 0.5 part of film-forming aid, 2 parts of filler, use 700-900r / min to disperse for 30-50min, add zirconium beads to grind, stop when the fineness is less than 20μm, add water-based polyester to disperse under the control speed of 1000-1500r / min stirring 25 parts of water-based hydroxyacrylic acid dispersion, 2 parts of thickener and 5 parts of remaining deionized water were added to adjust the viscosity to obtain component A;

[0040] (2) Preparation of component B: add 15 parts of envi...

Embodiment 2

[0043] A kind of coating for wrought iron guardrail spraying, coating comprises component A and component B, and the weight ratio of component A and component B is 7:1, and each raw material consumption of component A, component B is as shown in table 1 below,

[0044] The preparation method of described coating comprises the steps:

[0045] (1) Preparation of component A: Pour 15 parts of deionized water into the grinding tank, add 0.5 parts of defoamer, 0.3 parts of leveling agent, 7 parts of dispersant, 0.5 parts of film-forming aid, 2 parts of filler, use 700-900r / min to disperse for 30-50min, add zirconium beads to grind, stop when the fineness is less than 20μm, add 25 parts of water-based polyester dispersion, water-based hydroxyacrylic acid under stirring condition of 1000-1500r / min 20 parts of dispersion, add 2 parts of thickener and 5 parts of remaining deionized water to adjust the viscosity to obtain component A;

[0046] (2) Preparation of component B: Add 14 par...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap