A kind of repair material for extremely cold pavement and its preparation method and application

A kind of repair material and extremely cold technology, applied in the field of repair materials, can solve the problems of high and low temperature elongation, low temperature ductility, etc., and achieve the effect of avoiding volatilization and blocking the emission of irritating smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

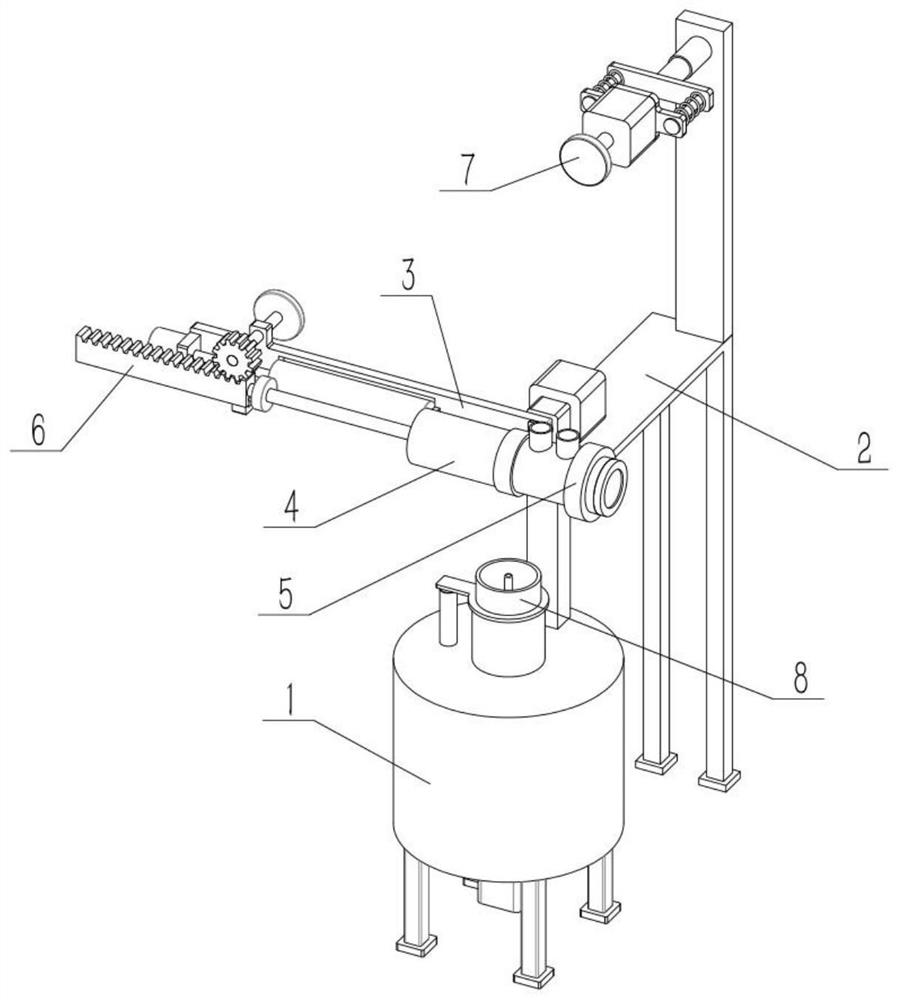

[0037] As shown in the figure, a method for preparing a repair material for extremely cold pavement includes the following steps:

[0038] Step 1: Pre-mix the materials with pungent odor in the raw materials of the repair material in a sealed environment to obtain pre-mixed raw materials;

[0039] Step 2, while performing step 1, hot-melting and stirring the resinous material to obtain hot-melting raw materials;

[0040] Step 3, mixing Portland cement, retarded sodium salt, fine sand and hot-melt raw materials to obtain preliminary raw materials;

[0041] Step 4: Aggregate and mix the premixed raw materials and the preliminary raw materials in a closed environment;

[0042] The above-mentioned method for preparing a repair material for an extremely cold pavement also relates to a device for preparing a repair material for an extremely cold pavement;

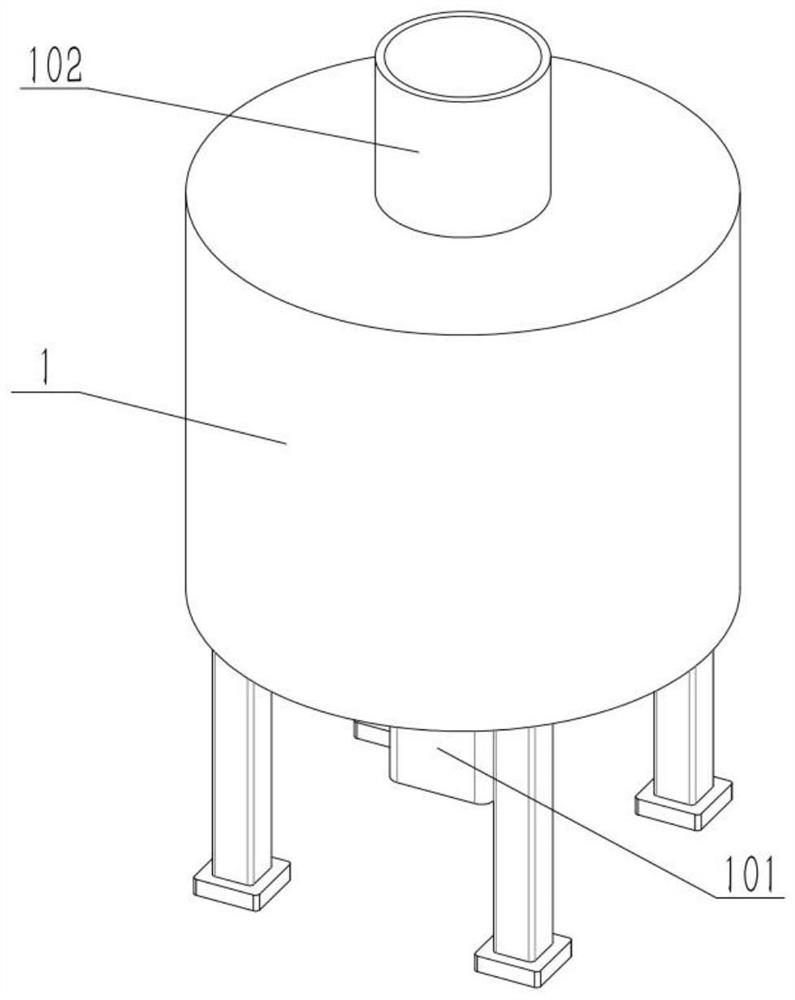

[0043]The device for preparing repairing materials for extremely cold roads includes a total mixing tank 1, a motor I101 and ...

specific Embodiment approach 2

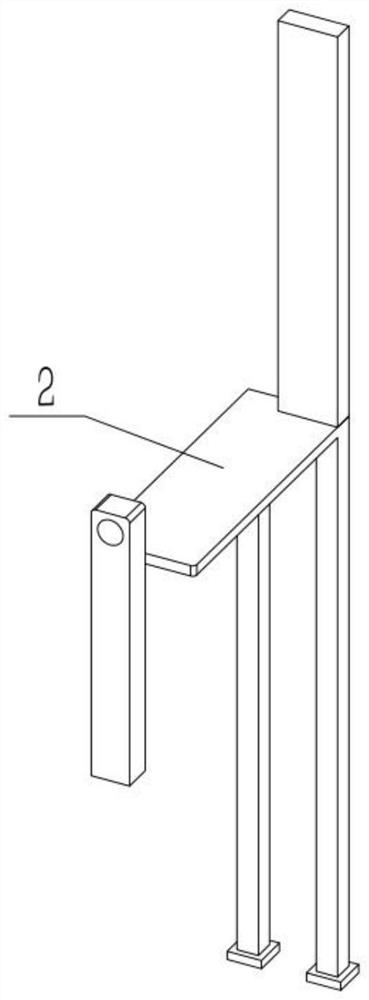

[0044] As shown in the figure, the apparatus for preparing repairing materials for extremely cold pavement further includes the frame 2, the central base 3, the motor II 301, the pre-pipe 4, the mounting seat 401 and the feeding tube 402. The rear end of the frame 2 is fixed on the On the front side of the upper end of the mixing tank 1, the rear end of the output shaft of the motor II 301 is fixed to the front end of the right end of the center base 3, the motor II 301 is fixed in the middle of the frame 2, and the middle of the output shaft of the motor II 301 is connected to the frame 2 in rotation. At the rear end, the middle part of the pre-pipe 4 is fixed to the mounting seat 401, the mounting seat 401 is fixed to the right side of the rear end of the central base 3, and the right side of the upper end of the pre-pipe 4 is fixed and connected to two feeding pipes 402, each feeding pipe 402 The upper ends are provided with covers for sealing and detachable. The cover and ...

specific Embodiment approach 3

[0045] As shown in the figure, the device for preparing repairing materials for extremely cold road also includes a shaft I304, a gear 306, a limit block 307, a rack 6, a shaft II601 and a piston 603. On the upper side, the rear end of the shaft I304 is fixed to the gear 306, the gear 306 meshes with the gear 306 for transmission, and the lower end of the gear 306 is provided with a groove that cooperates with the limit block 307, the limit block 307 is fixed with the center base 3, and the limit block 307 is in sliding connection with the groove, the right end of the rack 6 rotates to connect the shaft II 601 , the right end of the shaft II 601 is fixedly connected to the piston 603 , and the piston 603 is movably sealed in the pre-tube 4 . The outer ring of the piston 603 may be provided with a ring groove, and a piston ring may be provided in the ring groove to achieve the effect of a movable seal. Rotate the shaft II601, the shaft II601 drives the gear 306 to rotate, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com