High-efficiency quenching device for large-diameter rollers

A quenching device and large-diameter technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of large heat input, insufficient quenching, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

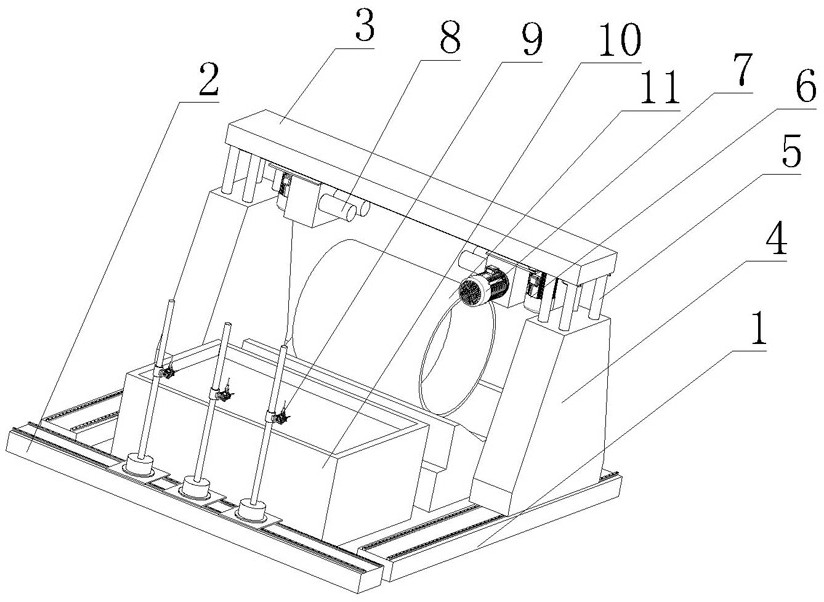

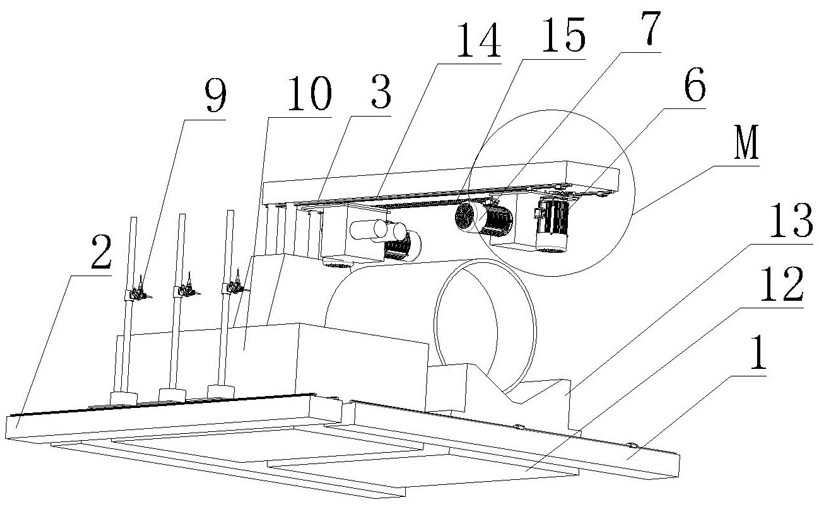

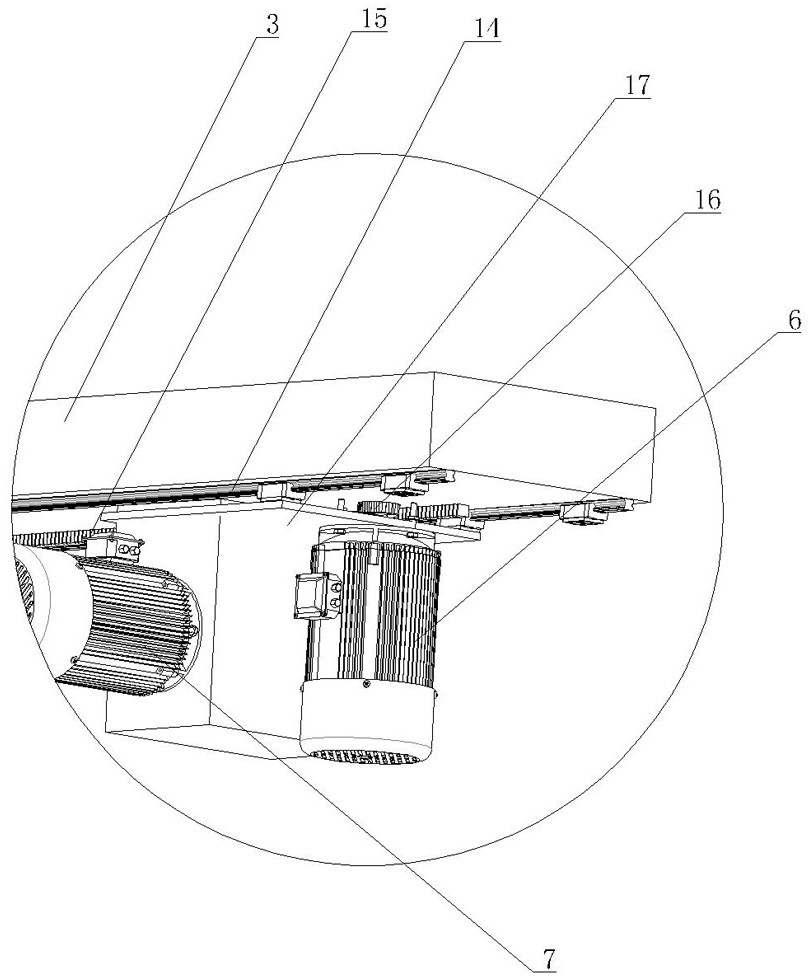

[0016] Referring to the accompanying drawings, this high-efficiency quenching device for large-diameter rollers includes a ground-rail gantry, a laser head 9, and a cooling pool 10. The ground-rail gantry includes a beam 3, two parallel Y-axis guide rails 1, and The column 4 is movable on two parallel Y-axis guide rails 2, the beam 3 is liftably mounted on the two movable columns 4, and the laser head 9 is movably installed on the X-axis guide rail 2 , at least two laser heads 9 are installed on the X-axis guide rail 2; in this embodiment, three laser heads 9 are respectively connected to three 6000W power lasers through optical fibers, and the quenching efficiency can reach 3-6m 2 / H, the laser heads 9 are installed side by side on the X-axis guide rail 2. As for how the laser head 9 moves on the X-axis guide rail, it is moved by gear transmission, which belongs to common knowledge and will not be repeated. The movement of the column 4 on the Y-axis guide rail can be promoted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com