Unlockable mortise and tenon joint self-locking type column-column connecting joint

A connection node, self-locking technology, applied in the direction of construction, building construction, etc., can solve the problems that bolt connection and weld connection operation space cannot be provided, bolt connection and weld connection cannot be realized, and it is difficult to ensure the removal of module units. , to achieve the effect of simple and easy-to-operate unlocking method, clear force transmission and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

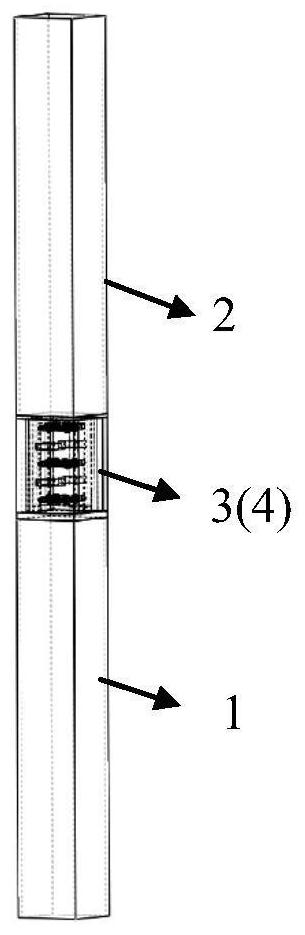

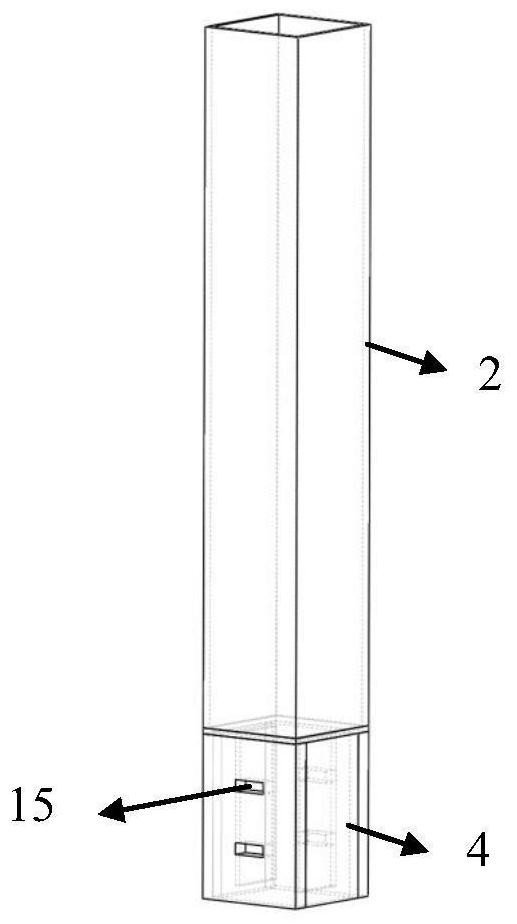

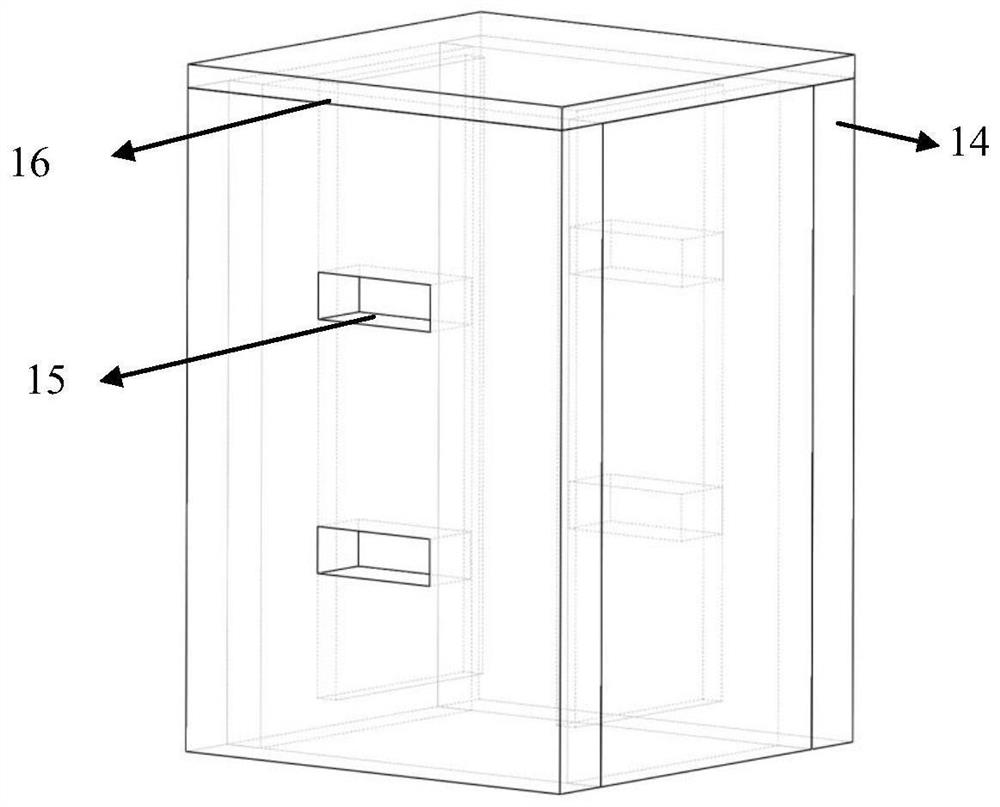

[0020] Such as Figure 1 to Figure 9 As shown, an unlockable mortise and tenon self-locking column-column connection node is mainly composed of a lower module column 1, an upper module column 2, an inner box 3 and an outer box 4, and the lower module column 1 is a square steel pipe column, the upper part of the lower module column 1 is connected to the connecting plate 12 provided at the bottom of the inner box 3 through a weld;

[0021] The inner box 3 includes an inner box frame 5, a connecting steel pipe 6, a gasket 7, an action plate 8, a limit block 9, a tenon 10, an action spring 11, a connecting plate 12 and a limit plate 13; the two action plates 8 pass through The limit block 9 is limited and fixed, and there is a distance between the two action plates 8; the action plate 8 has a through hole for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com