Connecting structure and construction method at joint of wall aluminum form and wood form

A technology for connecting structures and construction methods, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork/work frame, building construction, etc., and can solve problems that affect work efficiency, cumbersome operations, and simplicity. To achieve the effect of improving work efficiency and speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

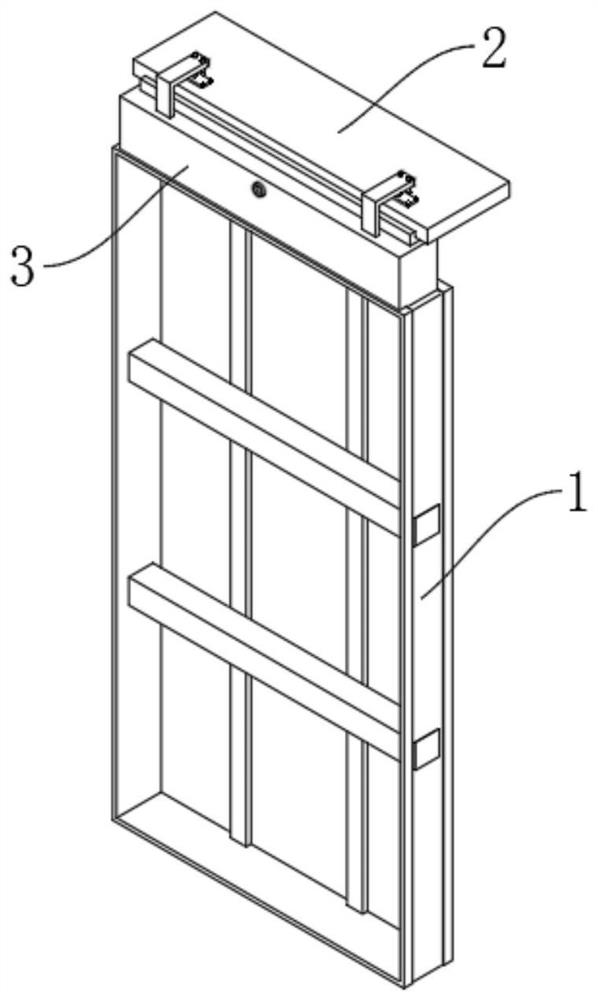

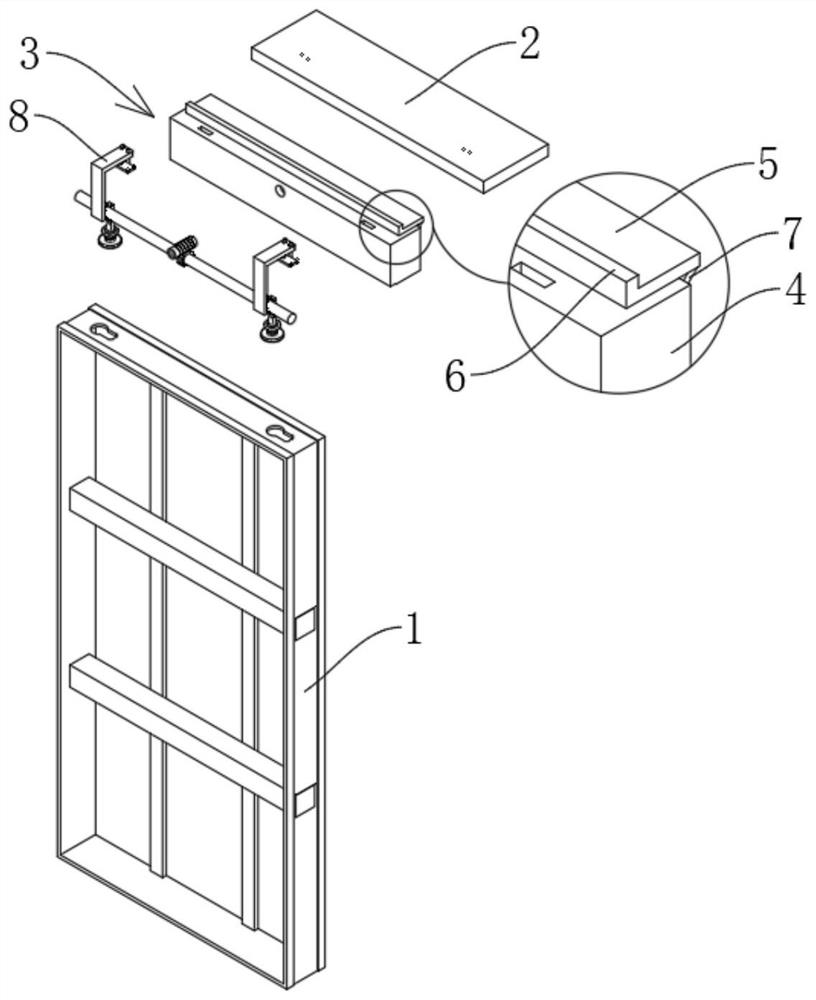

[0035] see Figure 1-3, the connection structure and construction method of the joint between the aluminum formwork and the wood formwork of the wall, including the connection structure of the joint between the aluminum formwork and the wood formwork of the wall, and the connection structure of the joint between the aluminum formwork and the wood formwork of the wall includes aluminum formwork 1 and wood formwork 2 , is characterized in that: a connection device 3 is installed between the aluminum formwork 1 and the wood formwork 2, the connection device 3 includes an installation shell 4, an auxiliary support plate 5 is fixedly connected to the top surface of the installation shell 4, and the auxiliary support plate 5 The edge is fixedly connected with the limit protrusion 6, the auxiliary support plate 5 and the limit protrusion 6 are matched with the wooden formwork 2, and a reinforcing oblique rod 7 is also fixedly connected between the auxiliary support plate 5 and the ins...

Embodiment 2

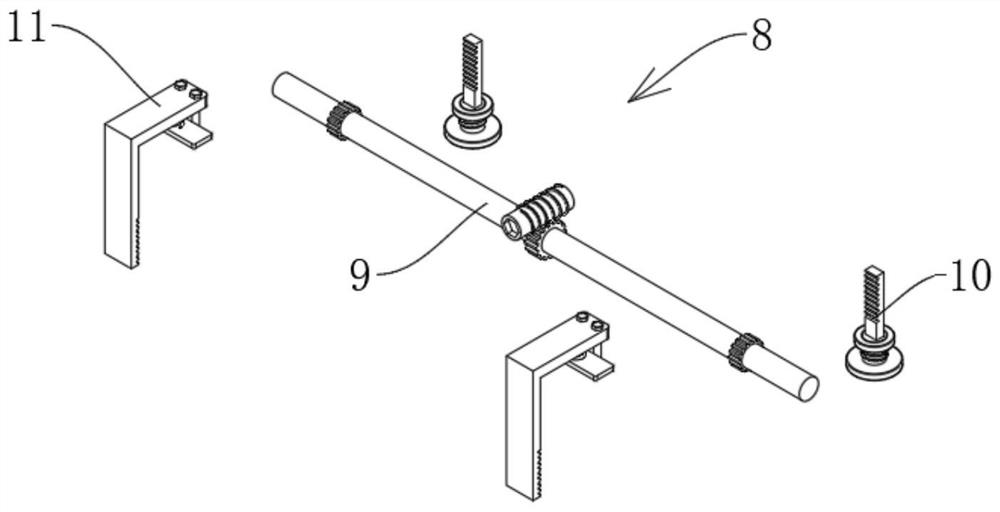

[0039] see Figure 4-6 , the difference with the basis of Embodiment 1 is that the adjustment mechanism 9 includes a connecting shaft 901, the connecting shaft 901 is rotatably connected to the inside of the installation housing 4, and the two ends of the connecting shaft 901 are fixedly connected with a driving gear 902, and the driving The gear 902 is matched with the aluminum formwork connection mechanism 10 and the wood formwork connection mechanism 11, and the middle position of the connection shaft 901 is fixedly connected with a worm wheel 903, and the worm wheel 903 is meshed with the worm 904, and the worm 904 is rotatably connected to the side wall of the installation housing 4 On the outer end of the worm 904 is provided with an adjustment groove 905 .

[0040] The aluminum formwork connecting mechanism 10 includes a first connecting rack 1001, which is slidably connected to the bottom surface of the installation housing 4, the first connecting rack 1001 is engaged ...

Embodiment 3

[0044] see Figure 5 , based on the basis of embodiment 1 or 2, the difference is that it also includes the construction method of the joint of the wall aluminum formwork and the wood formwork, the construction method of the wall aluminum formwork and the wood formwork, and the wall aluminum formwork and the wood formwork Matching the connection structure at the junction includes the following steps:

[0045] S1. According to the engineering design drawings, process and customize the standard size aluminum formwork 1, wood formwork 2 and connecting device 3 used in conjunction with the actual project;

[0046] S2. Use steel profiles to make the back flute as a reinforcement structure, use adjustable sleeve-type steel supports as a support structure, and then use pins to fix the front of the aluminum formwork;

[0047] S3. Complete the pre-assembly in the factory according to the design drawings, and after meeting the engineering requirements, mark all the aluminum formwork 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com