Device for increasing face width of forepolings during working face for recovering main roadway coal pillars passing through empty roadway

A technology of advanced support and working face, which is applied in the direction of mining equipment, mine roof support, mining equipment, etc., can solve the problems of severe mine pressure, large range of changes, and large gaps, etc., to enhance applicability, improve stability, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below, but protection scope of the present invention is not limited to the scope of the specific embodiment described below:

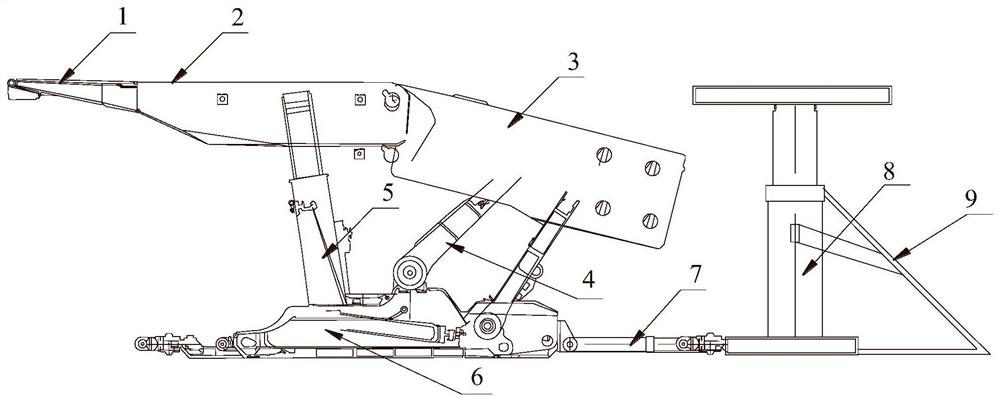

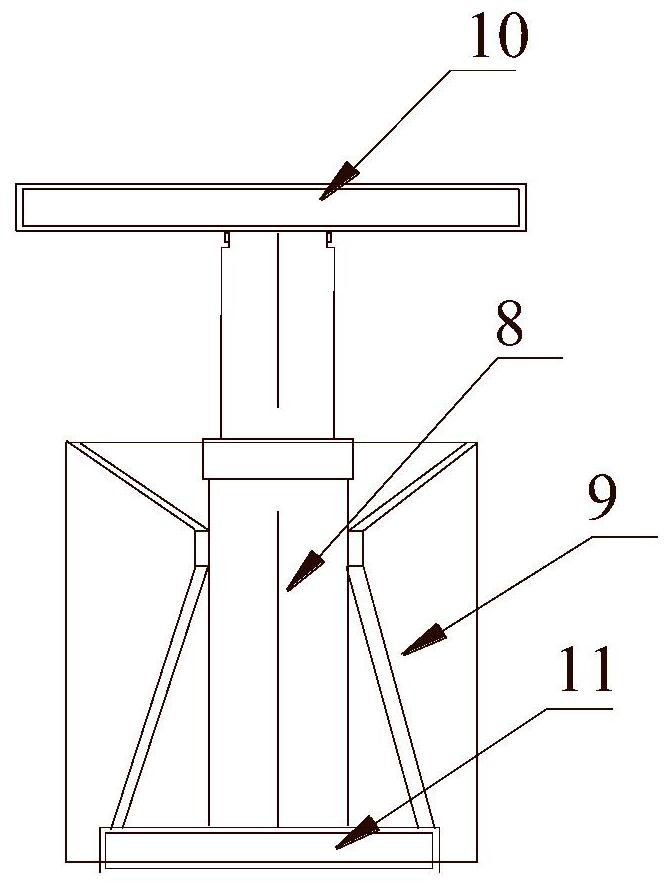

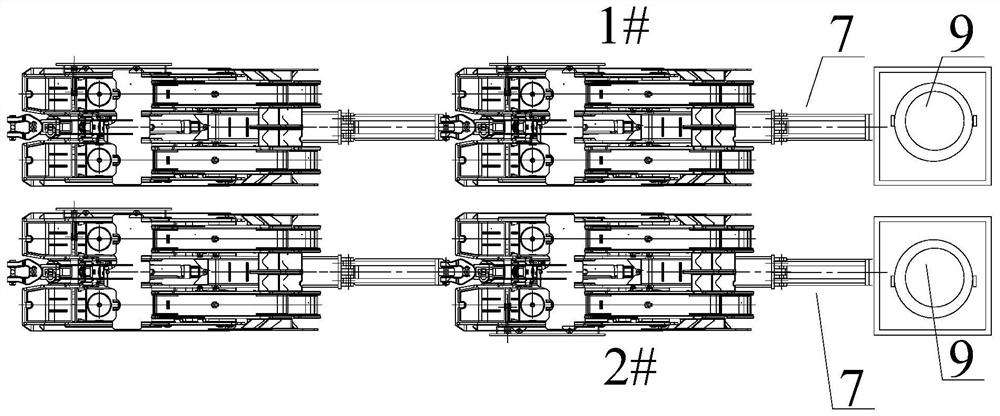

[0023] combine figure 1 and figure 2 As shown in the figure, a device for increasing the distance between the top and the top of the gob-side support on the coal pillar working face of the recovery roadway is composed of a front beam 1, a top beam 2, a cover beam 3, a connecting rod 4, a column 5, a support base 6, an oil cylinder 7, The pier column 8, the pier column retaining board 9, the pier column top plate 10, and the pier column base 11 are composed. The front beam 1 is connected to the top beam 2, the cover beam 3 is hinged to the top beam 2, the upper end of the connecting rod 4 is welded to the cover beam 3, the lower end of the connecting rod 4 is hinged to the bracket base 6, and the upper end of the column 5 is connected to the top beam 2 are connected, the lower end of the column 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com