Automobile engine shell size detection device and detection method thereof

A technology for automobile engine and size detection, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of reduced applicability, difficult configuration for small and medium-sized enterprises, and high cost of testing equipment, and achieve the effect of convenient installation and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

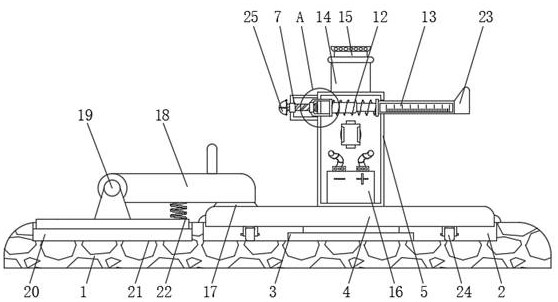

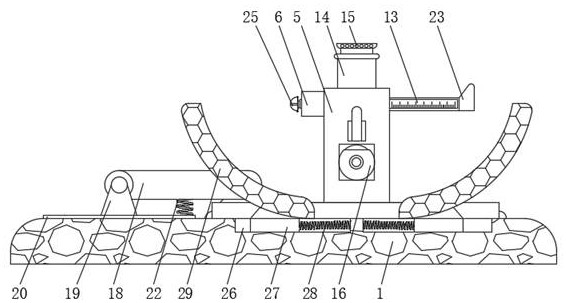

[0027] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

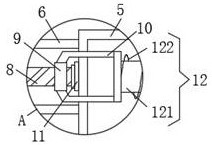

[0028] Such as Figure 1-3 As shown, the present invention provides a technical solution: a vehicle engine casing size detection device, including a base 1, the upper surface of the base 1 is provided with a first groove 2, and the lower surface of the inner wall of the first groove 2 is clamped with a The first rotating mechanism 3, the top of the first rotating mechanism 3 is fixedly connected with the turntable 4, the upper surface of the turntable 4 is fixedly connected with the casing 5, the left side and the back of the casing 5 are fixedly connected with the protective shell 6, two Bearings 7 are clamped on the left side and the back of the protective case 6, and threaded rods 8 are sleeved in the two bearings 7. The right end of the threaded rods 8 is fixedly connected to the left end of the rotating assembly 11, and the clamping of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com