Method for testing and evaluating sound quality of automobile electric device

A technology for automotive electrical appliances and evaluation methods, which is applied to electrical components, instruments, measuring devices, etc., can solve the problems of diverse sound components, not very wide applicability, and low hearing sense correlation, so as to improve systemic and professional, The effect of a good sound experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

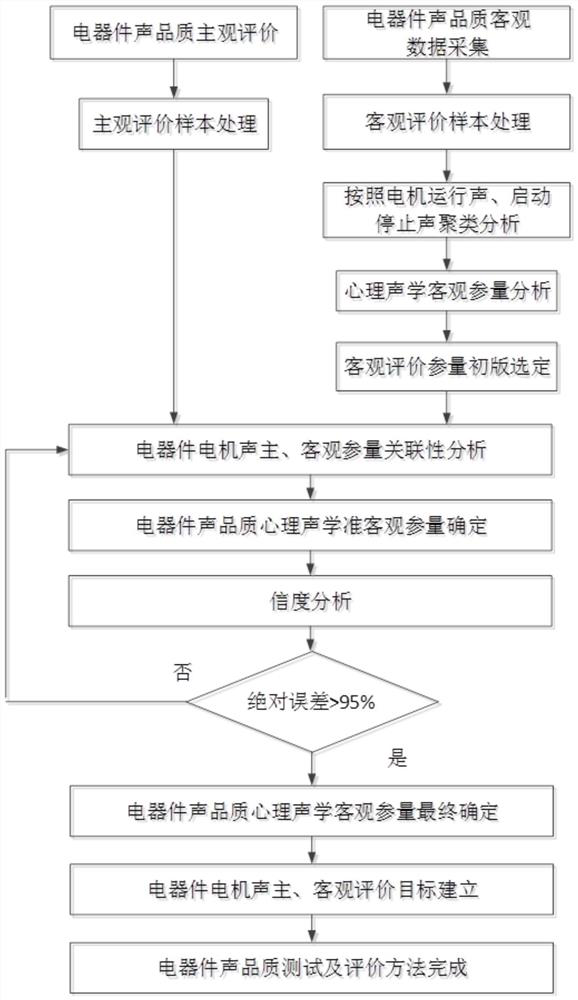

[0046] A method for testing and evaluating the sound quality of automotive electrical components, comprising the following steps:

[0047] S1. Subjective evaluation of the sound quality of electrical components in the vehicle state, the specific method is as follows:

[0048] 1. Evaluation position: the driver's position.

[0049] 2. Operation method: The battery of the vehicle is fully charged and is in the power-on state. Manipulations were run by the evaluation system in triplicate.

[0050] 3. Evaluation content: evaluate the sound of the motor running during the operation of the system; evaluate the sound of the motor starting and stopping during the operation of the system.

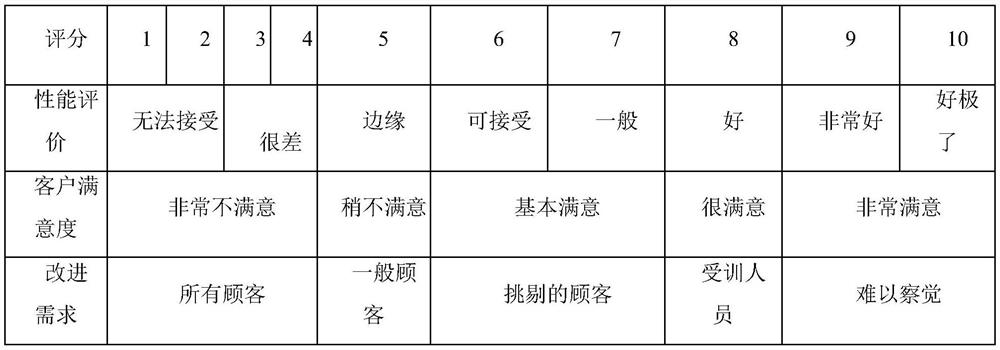

[0051] 4. The subjective evaluation method adopts a 10-point system, and the minimum unit of the evaluation score is 0.25 points. The scoring standards are shown in Table 1. When making statistics, take the average of the scores of the sound quality of each evaluated system of the evaluation group,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com