Chip mounter for resistor processing

A chip mounter and resistor technology, applied to electrical components, electrical components, printed circuits, etc., can solve problems affecting the quality of mounting, unstable connection between resistors and circuit boards, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

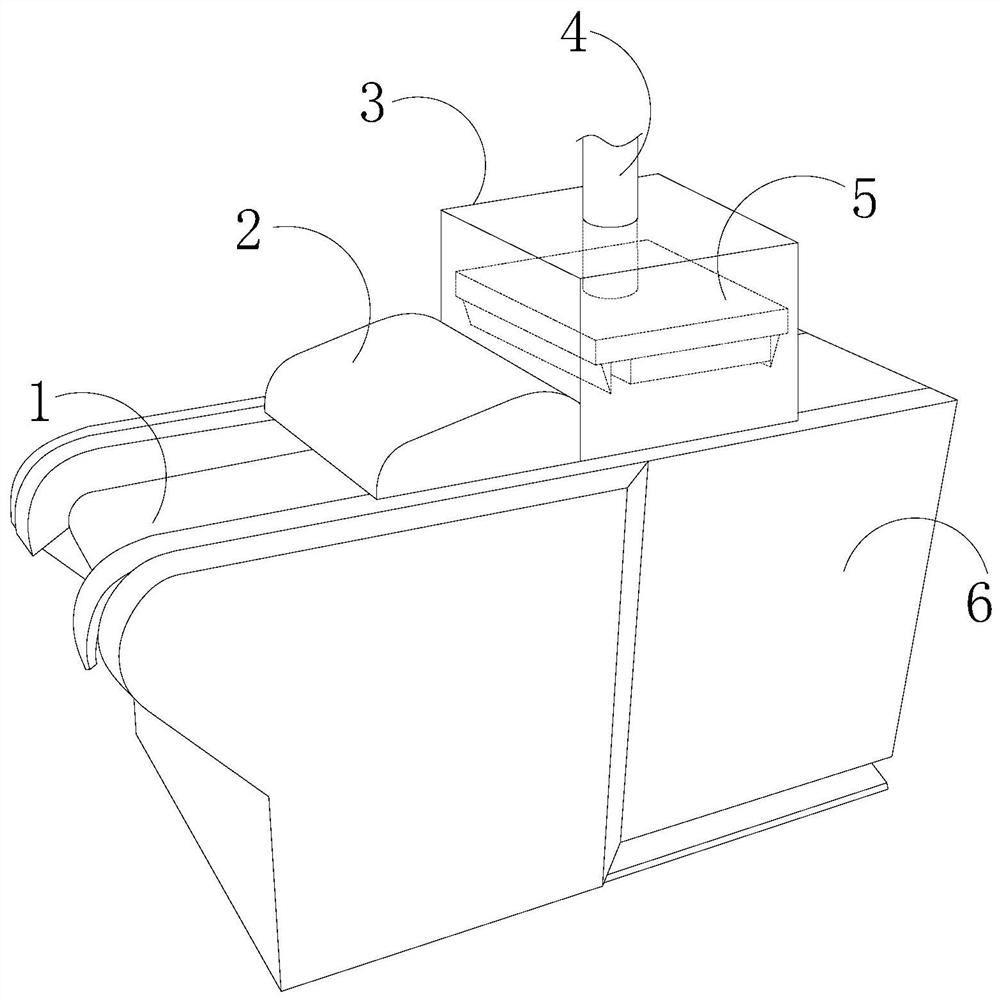

[0025] see Figure 1-Figure 5 , the present invention provides a placement machine for resistance processing, its structure includes a conveyor belt 1, a protective cover 2, a placement box 3, a drive rod 4, a placement device 5, and a frame 5, and the conveyor belt 1 is installed on the frame 5 Top, the top of the base 5 is provided with a protective cover 2, the protective cover 2 and the patch box 3 are located on the same horizontal line, the patch box 3 is provided with a patch device 5, and the patch device 5 Mechanically connected with the drive rod 4, the drive rod 4 runs through the patch box 3, and the drive rod 4 is connected with the external mechanical force, so that the patch device 5 can be driven up and down to achieve patching;

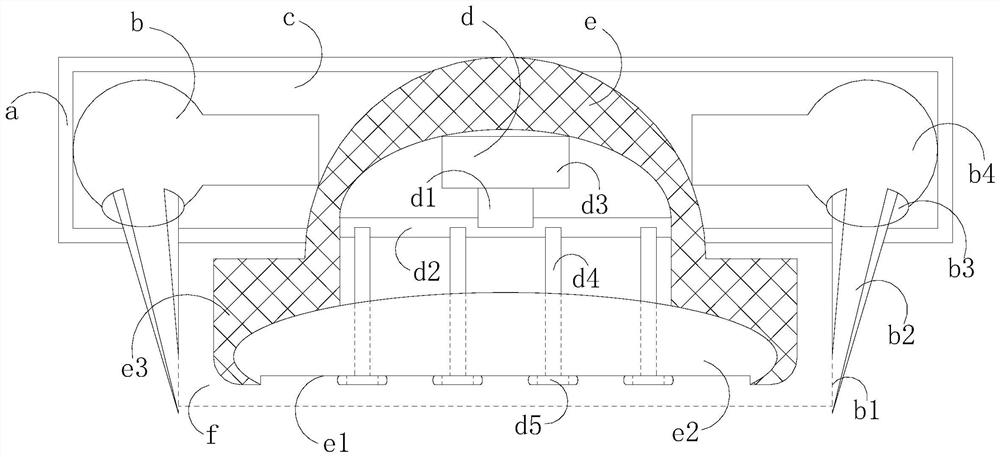

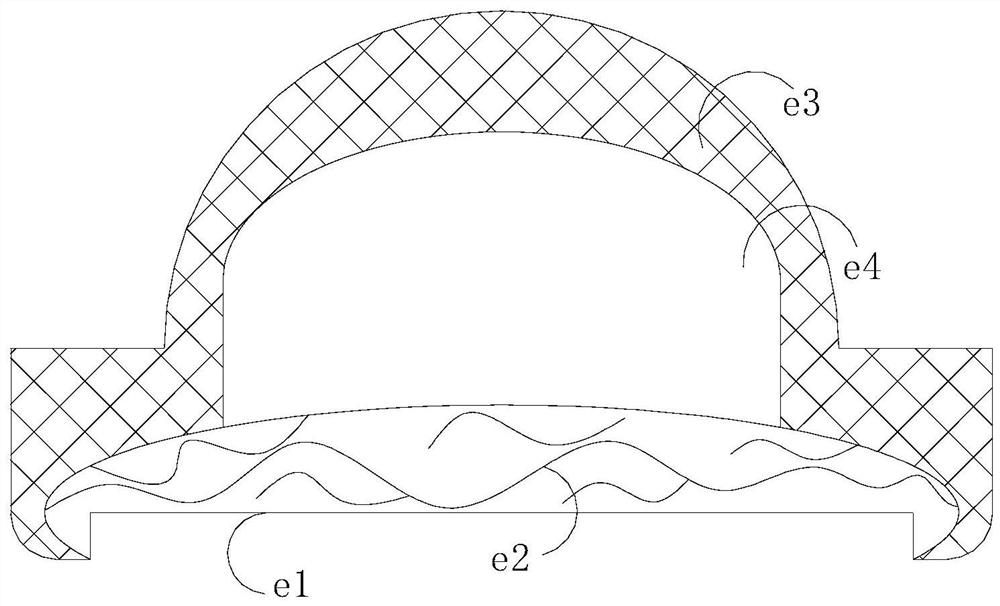

[0026] The patch device 5 is composed of a fixed frame a, a cooling mechanism b, a rectangular cavity c, a solder filling head d, a patch plate e, and a working cavity f. The cavity surrounded by the fixed frame a is a rectangular cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com