Gluing control method and system

A control method and control system technology, applied in the field of mechanical and electrical production lines, can solve problems such as low glue application efficiency, difficulty in meeting production requirements, and inability to automate glue application, so as to achieve the effects of improving operation efficiency, ensuring quality, and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

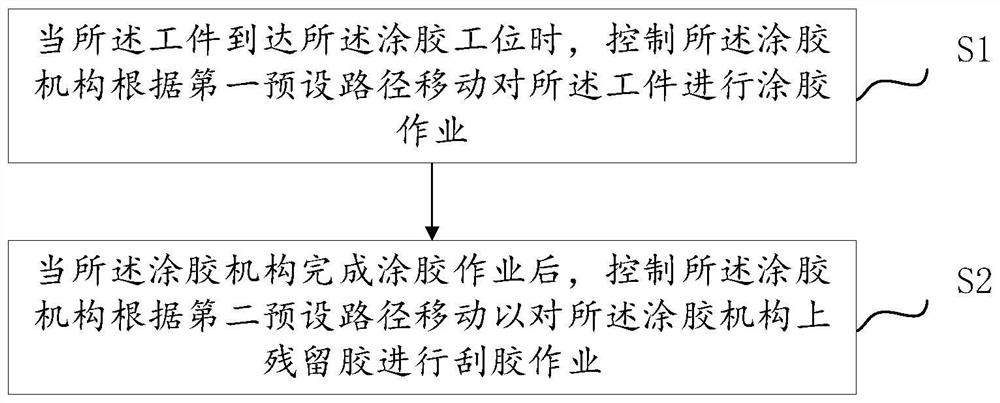

[0051] This embodiment provides a gluing control method, which is mainly used to control the displacement of the gluing mechanism in the automatic gluing device to cooperate with the workpiece to realize the gluing operation on the workpiece. figure 2 shown, including the following steps:

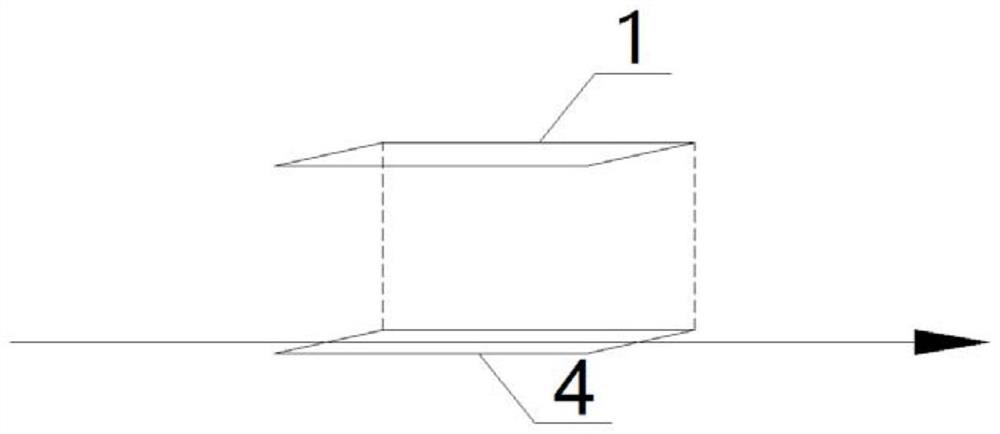

[0052] S1: When the workpiece reaches the gluing station 1, control the gluing mechanism to move according to the first preset path to apply gluing to the workpiece;

[0053] S2: After the gluing mechanism completes the gluing operation, control the gluing mechanism to move according to the second preset path to scrape the residual glue on the gluing mechanism.

[0054] In an exemplary embodiment, the workpiece can be placed on the gluing station 1 manually or automatically by a robot to be regarded as the workpiece arrives at the gluing station 1 . Among them, in order to ensure that when the workpiece arrives at the gluing station 1, the automatic gluing device can automatically identif...

Embodiment 2

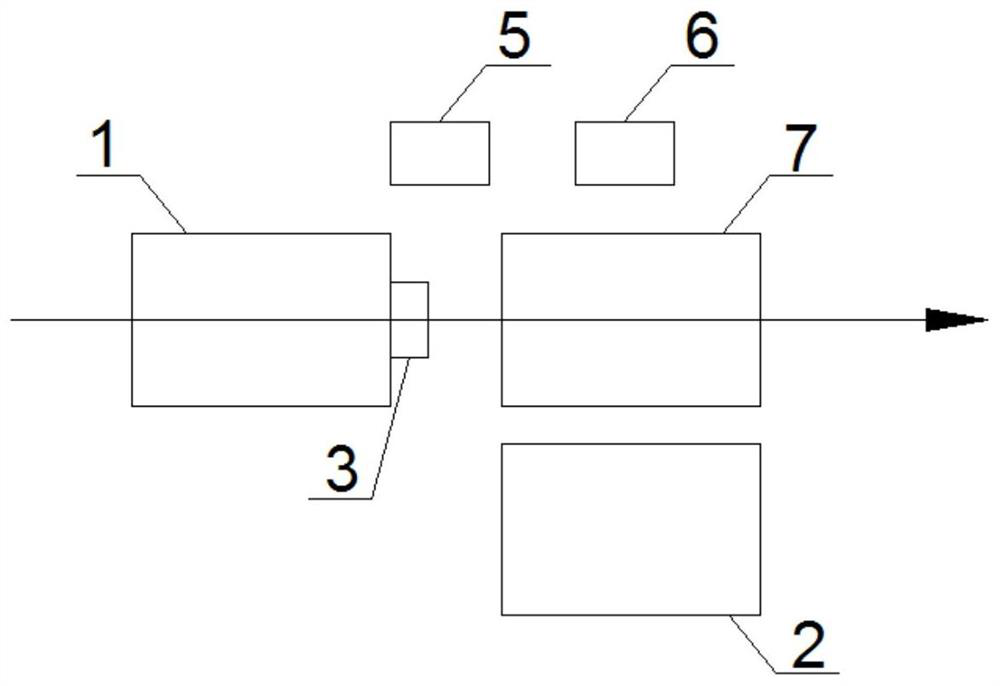

[0075] This embodiment provides a gluing control system to control the gluing mechanism and the workpiece. Such as Figure 5 As shown, the control system includes a gluing control module 8 and a squeegee control module 9 .

[0076] The gluing control module 8 is used to control the gluing mechanism to move the gluing mechanism to the workpiece according to the first preset path when the workpiece reaches the gluing station 1;

[0077] The squeegee control module 9 is used to control the gluing mechanism to move according to the second preset path after the gluing mechanism completes the gluing operation so as to carry out the squeegee operation on the residual glue on the gluing mechanism.

[0078]In an exemplary embodiment, the workpiece can be placed on the gluing station 1 manually or automatically by a robot to be regarded as the workpiece arrives at the gluing station 1 . Among them, in order to ensure that when the workpiece arrives at the gluing station 1, the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com