Sand mold of engine cylinder cover casting mold and manufacturing method thereof

A technology for engine cylinder heads and molds, which is applied in the field of casting of mechanical parts, can solve problems such as complex inner cavity mud core structure, inaccurate positioning of sand molds, and troublesome assembly, so as to solve the problem of unclean loose sand cleaning and improve production Speed and quality, the effect of avoiding core fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

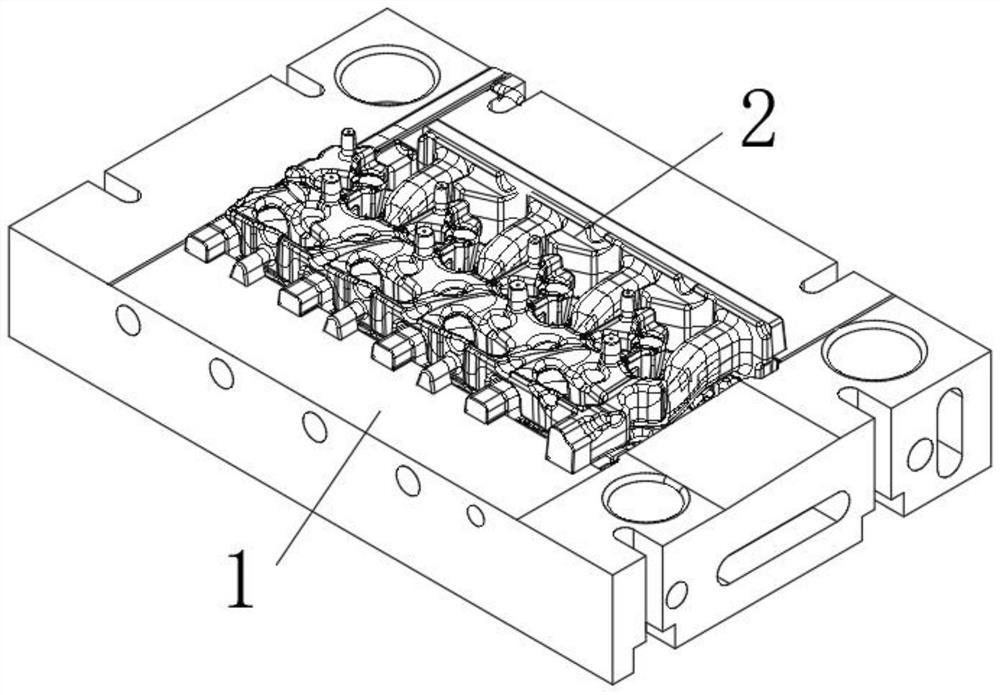

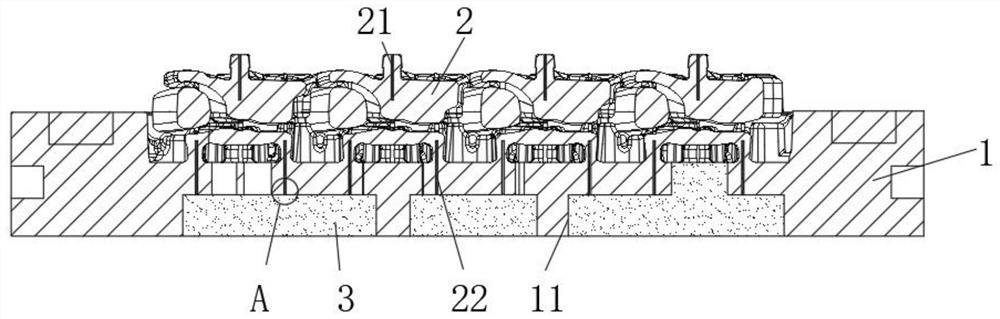

[0033] A sand mold for an engine cylinder head casting mold, comprising a sand mold 1, a mud core 2 is provided at the center of the sand mold 1, and the sand mold 1 and the mud core 2 are integrally produced by 3D printing; the bottom surface of the sand mold 1 is provided with There are a plurality of observation windows 11, and the observation windows 11 are relatively communicated with the cavity in the mud core 2; the inside of the observation windows 11 is connected with a sealing mud block 3; the inner weak position of the mud core 2 is reserved with Reinforcing hole, the interior of the reinforcing hole is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com