Clamping device for welding robot

A welding robot and clamping device technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult to clamp arc surface structure parts, limit the use range, etc., and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

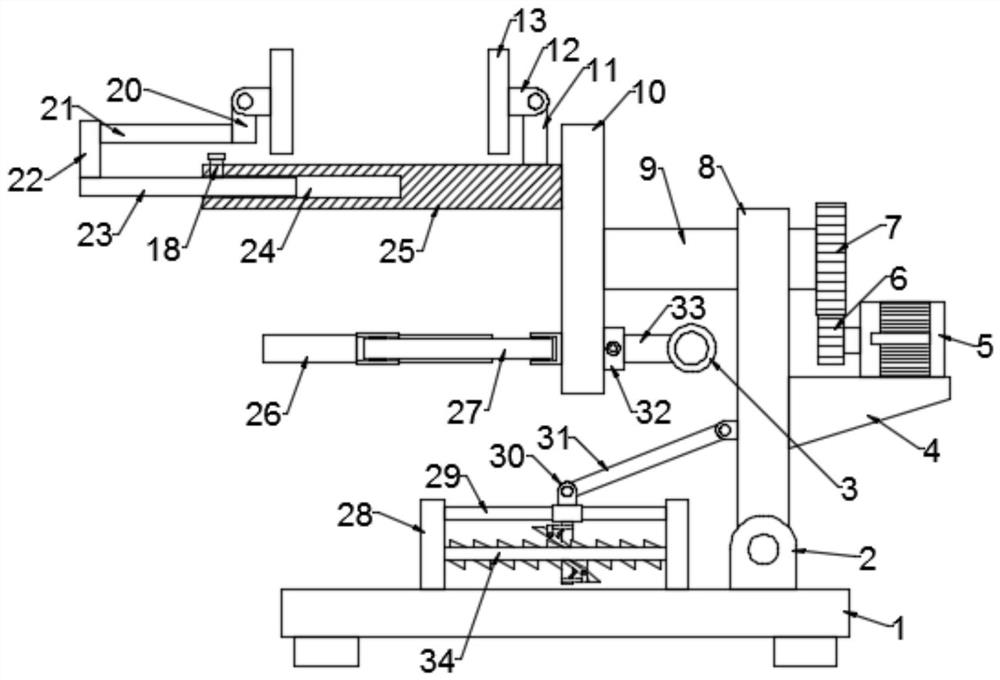

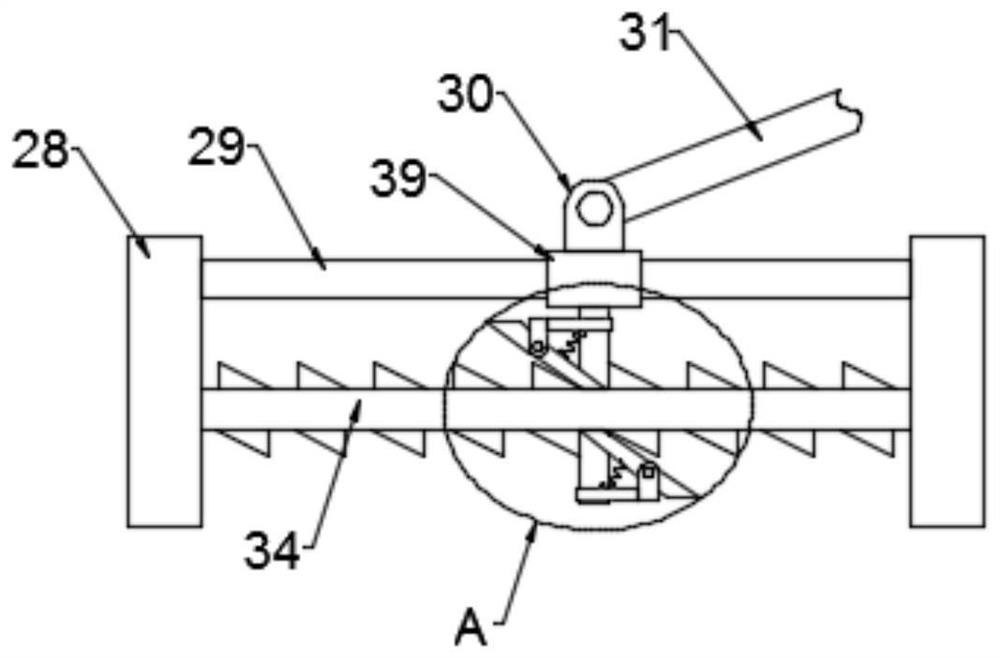

[0031] see Figure 1-5 , in an embodiment of the present invention, a clamping device for a welding robot includes a bottom plate 1, a turntable 10 is arranged on the upper side of the bottom plate 1, and a horizontal plate 25 is fixed on the turntable 10; Rod 11 and moving rod 20, fixed rod 11 is fixed on the horizontal plate 25, and horizontal plate 25 is provided with the adjusting assembly that is used to adjust the position of moving rod 20, and the fixed rod 11 and the moving rod 20 are hinged with the second support 12, A flat plate 13 is installed on the second support 12;

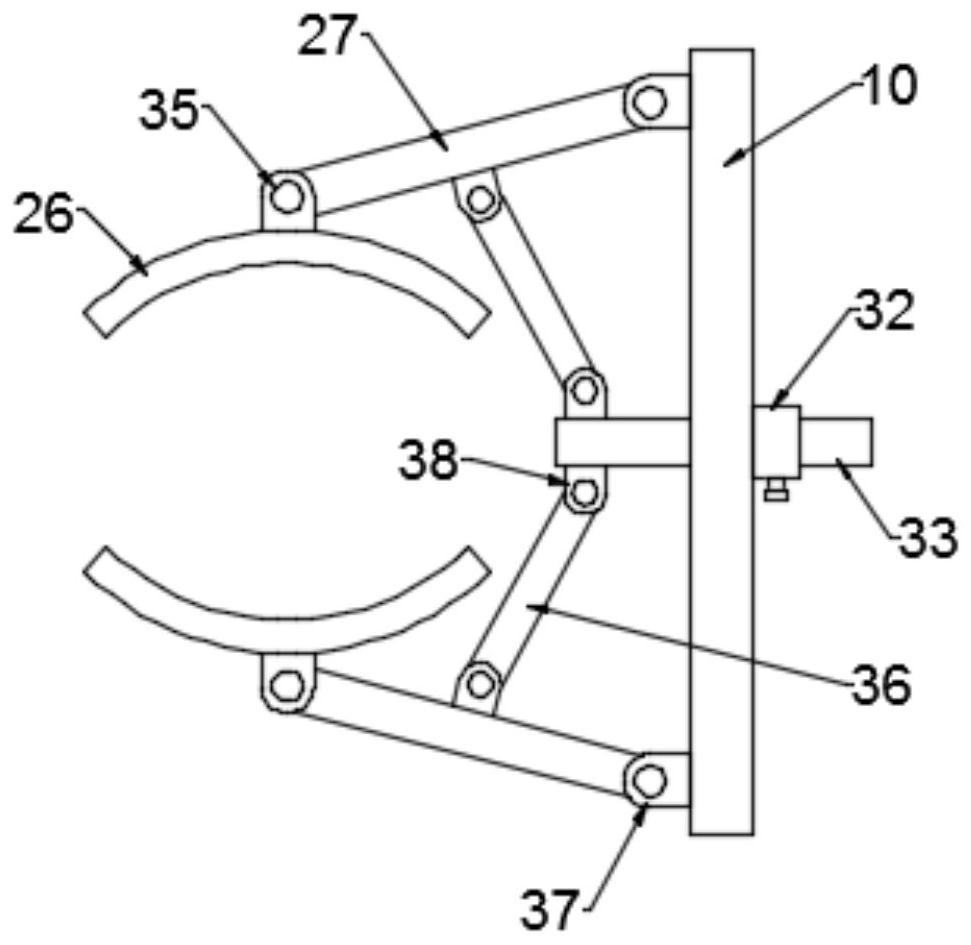

[0032] Two sixth supports 37 arranged symmetrically are installed on the turntable 10, the sixth support 37 is hinged with a push rod 27, and the end of the push rod 27 away from the sixth support 37 is hinged with a fifth support 35. The arc rod 26 is installed on the five support 35, and the pull-out assembly for driving the ejector rod 27 to rotate is arranged on the turntable 10; when in use, ...

Embodiment 2

[0044] see Figure 6 , in the embodiment of the present invention, a clamping device for a welding robot is different from Embodiment 1 in that a hydraulic cylinder 19 is provided on the cross bar 21, and a first sliding sleeve 17 is provided on the telescopic end of the hydraulic cylinder 19. , the first slide sleeve 17 is slidably provided with a slide bar 16, the slide bar 16 is hinged with a third support 15, and the bottom of the third support 15 is provided with a pressure plate 14; the first slide sleeve 17 is moved up and down by a hydraulic cylinder 19, And translate the slide bar 16, so that the pressing plate 14 is pressed on the upper part of the part to enhance the stability of the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com