Filter element dismounting device

A technology for dismantling device and filter element, applied in the field of tools, can solve the problems that the quality of pure water cannot meet the technological requirements, is difficult to grasp, is labor-intensive and time-consuming, etc., and achieves the effect of simple and fast disassembly work, labor-saving operation, and quick disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

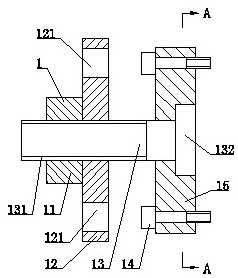

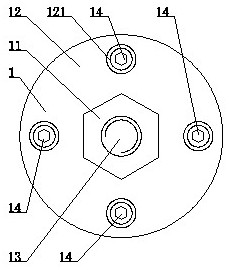

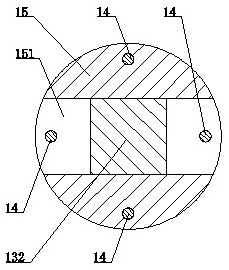

[0012] see Figure 1 to Figure 6 , the present invention includes a water purification filter cartridge 2, the water purification filter cartridge 2 includes an outer cylinder 21, several locking assemblies 22 and filter elements 23, each of the locking assemblies 22 includes a locking screw 221 and a pressure plate 222, and also includes a removal tool 1. The removal tool 1 includes a fine-thread nut 11, a positioning plate 12, a pull rod 13, a connecting plate 15 and several screws 14, and several round holes 121 are arranged on the positioning plate 12. The outer circular surface of the left part is provided with a fine-toothed external thread 131, and the right part of the pull rod 13 is provided with a square tenon 132, and the right end surface of the connecting plate 15 is provided with a slot 151, and the fine-toothed The nut 11 is mounted on the left part of the pull rod 13 through threaded connection, the square tenon 132 on the right part of the pull rod 13 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com