Suction type sanitation garbage truck

A technology for sanitation and garbage, applied in the field of sanitation, can solve the problems of reducing the friction coefficient, increasing the amount of garbage collected, increasing the density, etc., and achieve the effect of reducing oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

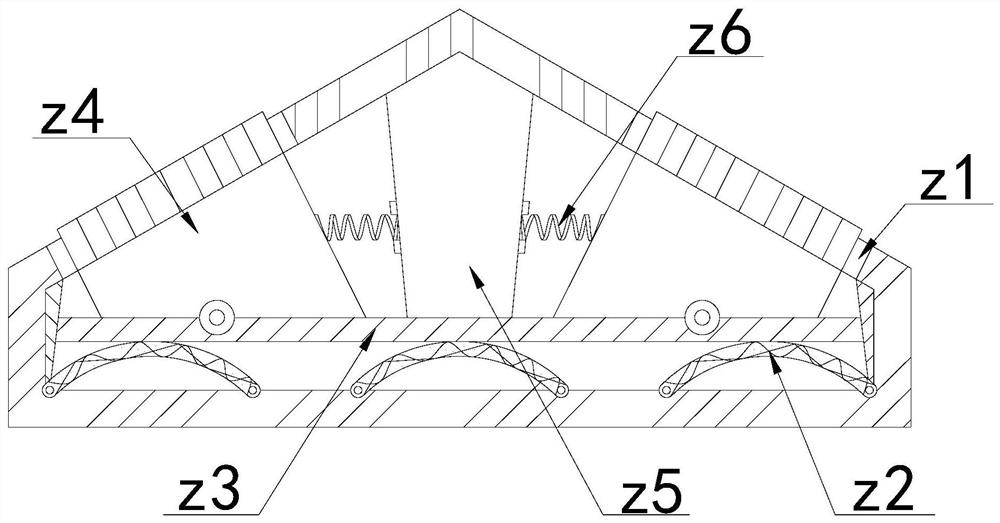

[0027] as attached figure 1 to attach Figure 5 Shown:

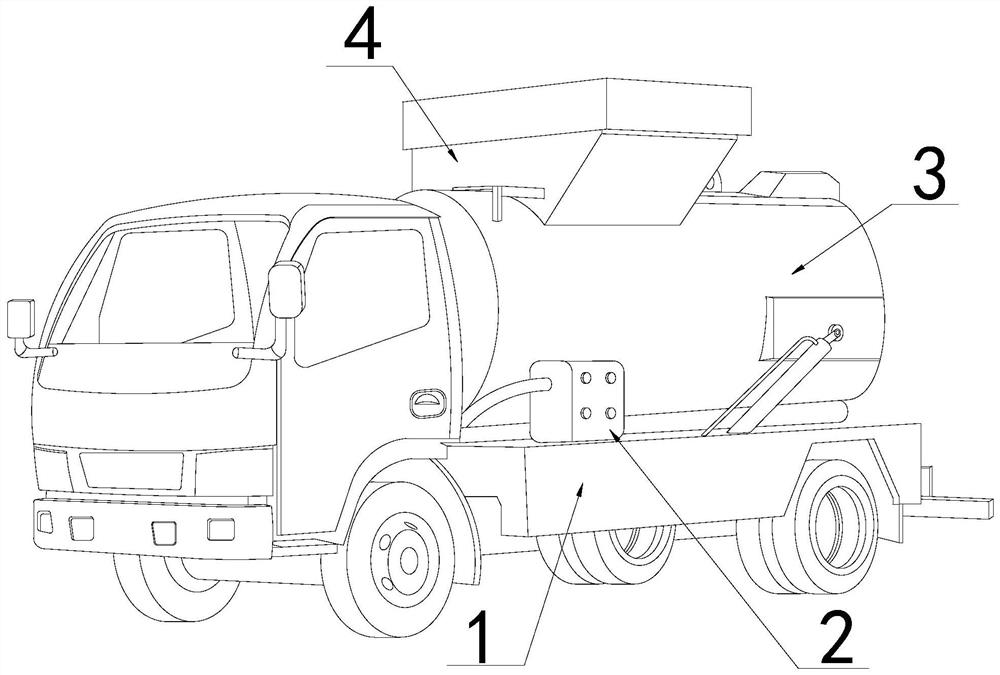

[0028] The present invention provides a suction-mounted sanitation garbage collection and transportation vehicle, the structure of which includes a transport vehicle 1, a distribution box 2, a container 3, and a feeding hopper 4. The container 3 is fixed on the top of the right side of the transport vehicle 1, and the distribution box The electrical box 2 is installed on the bottom of the front side of the container 3 , and the feed hopper 4 communicates with the top of the container 3 .

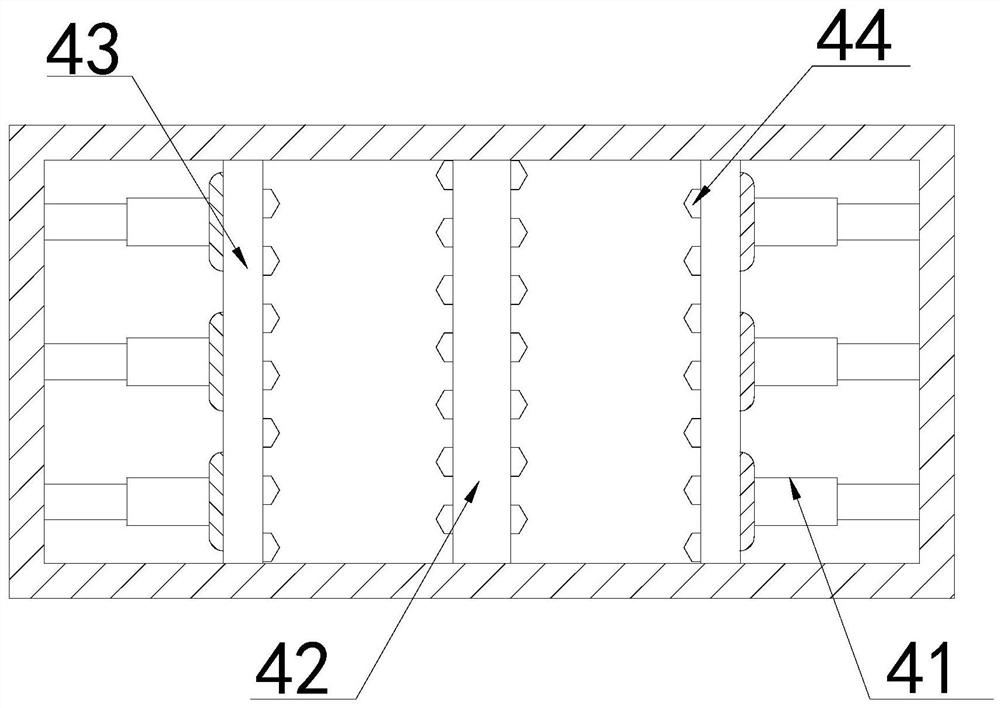

[0029] The feed hopper 4 is provided with a push rod 41, a support plate 42, a moving plate 43, and a block 44. The push rod 41 is respectively arranged on both sides of the inner wall of the feed hopper 4, and is movably matched with the moving plate 43. The support plate 42 is fixed at the center position inside the feed hopper 4 , and the blocks 44 are respectively fixed on the surfaces of the support plate 42 and the moving plate...

Embodiment 2

[0036] as attached Image 6 to attach Figure 8 Shown:

[0037] Wherein, the groove x1 is provided with a side rod v1, a rolling ball v2, a brush ring v3, a partition v4, and a rotating rod v5, the side rod v1 is fixed in the middle part of the inner wall on the right side of the groove x1, and the rolling ball v2 is set Inside the side bar v1, the brush ring v3 is installed on the left end of the side bar v1, the partition v4 is fixed to the right inside the groove x1, the rotating rod v5 runs through the upper middle and lower part of the partition v4, and the roller There are two balls v2, which are made of steel and have a greater gravity, so that the sidestick v1 is subject to greater gravity swing.

[0038] Wherein, the rotating rod v5 is provided with an inner groove b1, a clamping ball b2, and a brush block b3. Fixed on the outer surface of the rotating rod v5, there are eight brush blocks b3, which are arc-shaped, which is conducive to uniform contact with the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com