Bulk heterojunction organic thin-film solar cell and preparation method thereof

A solar cell and bulk heterojunction technology, applied in the field of solar energy, can solve problems such as destroying the interface structure, weakening the stability of organic thin film solar cells, and erosion, and achieves the effects of simple process, improved ability to resist photochemical reactions, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

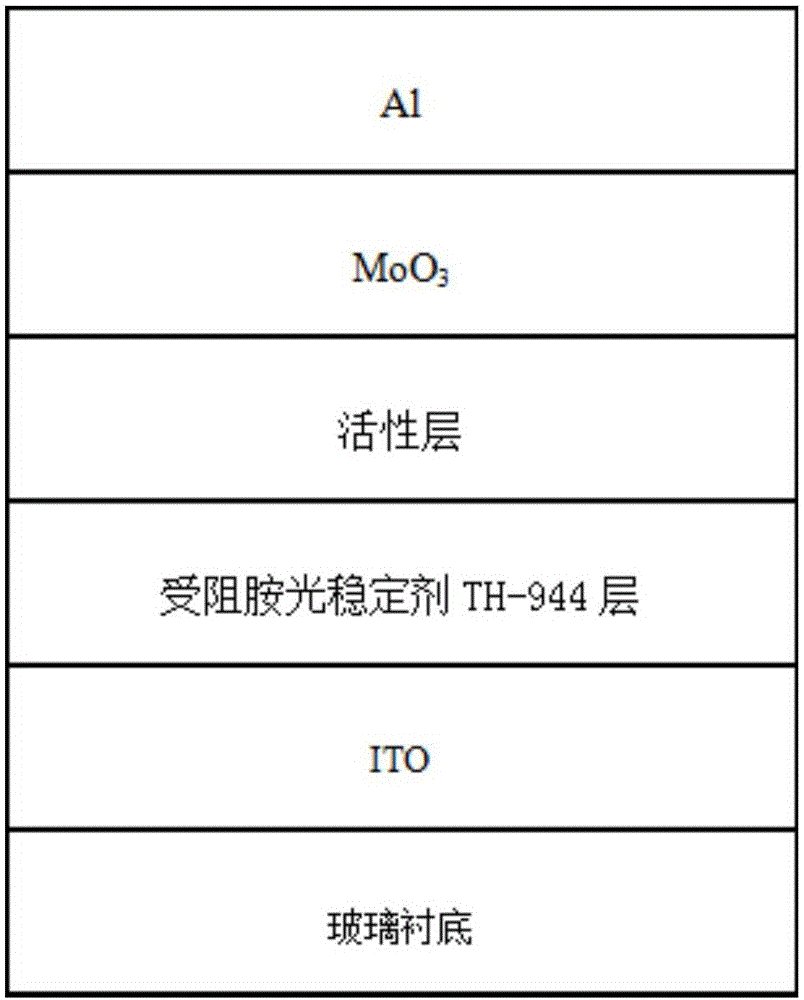

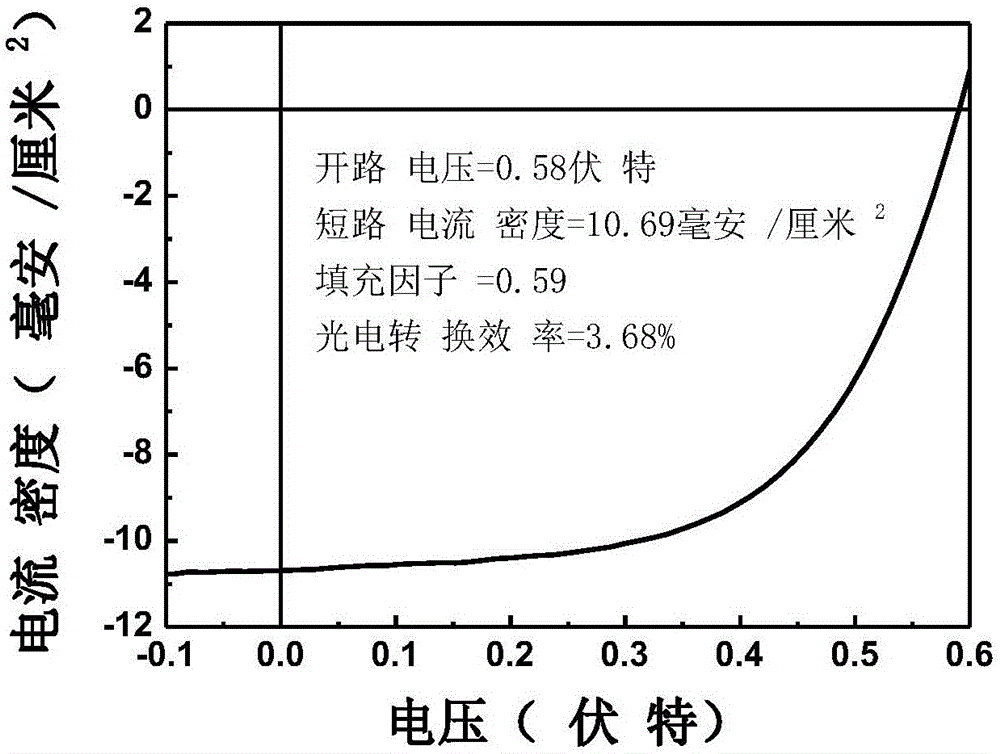

[0047] With acetone as a solvent, a solution of hindered amine light stabilizer TH-944 with a concentration of 0.5% (w / w) was prepared for use. P3HT was mixed with PC61BM at a concentration of 17 mg / ml at a ratio of 1:1 (W:W) and dissolved in dichlorobenzene. The mixed solution was heated and stirred at 60°C for 12 hours, and then used. Sonicate the ITO transparent substrate with washing solution, deionized water, acetone, and ethanol twice for 15 minutes, and blow dry with nitrogen. The prepared hindered amine light stabilizer TH-944 solution was spin-coated on the ITO substrate by the spin-coating method at a speed of 3500 rpm for 60 s. Dry naturally in the air for 2 hours to form a cathode modification layer. The heterojunction active layer P3HT:PC61BM was spin-coated on the cathode modification layer at a rotation speed of 800 rpm for 60 s. After 1 hour of natural drying in a nitrogen environment, annealing at 120°C for 20 minutes. Sequentially use high vacuum thermal e...

Embodiment 2

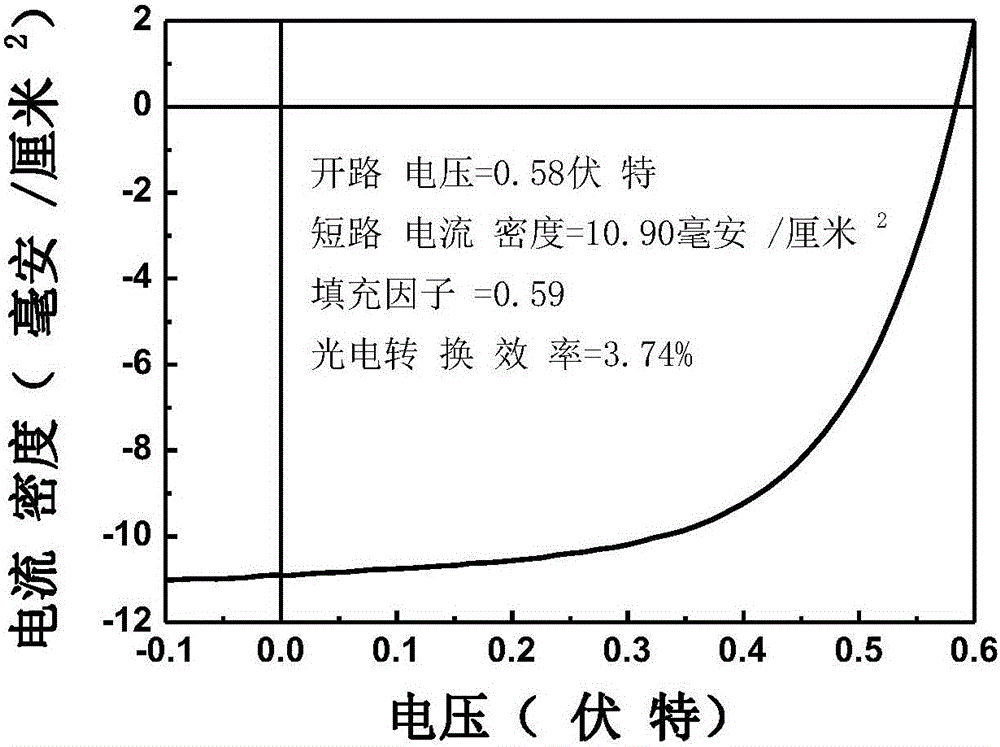

[0050] Using acetone as a solvent, a 2% (w / w) hindered amine light stabilizer TH-944 solution was prepared for use. P3HT was mixed with PC61BM at a concentration of 17 mg / ml at a ratio of 1:1 (W:W) and dissolved in dichlorobenzene. The mixed solution was heated and stirred at 60°C for 12 hours, and then used. Sonicate the ITO transparent substrate with washing solution, deionized water, acetone, and ethanol twice for 15 minutes, and blow dry with nitrogen. Soak the ITO transparent substrate in the prepared hindered amine light stabilizer TH-944 solution for 2 hours to form a self-assembly process. The soaked ITO transparent substrate was taken out, rinsed with acetone and dried naturally to form a cathode modification layer. The heterojunction active layer P3HT:PC61BM was spin-coated on the cathode modification layer at a rotation speed of 800 rpm for 60 s. After 1 hour of natural drying in a nitrogen environment, annealing at 120°C for 20 minutes. Sequentially use high vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com