Small-diameter optical lens surface scratch detection device

A technology of optical lenses and detection devices, applied in measuring devices, material analysis through optical means, scientific instruments, etc., can solve problems such as visual fatigue, inability to accurately find scratches, and inconvenient positioning of scratches, etc., to achieve increased Extend the range, improve the collection rate of water body, and improve the effect of all-round blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

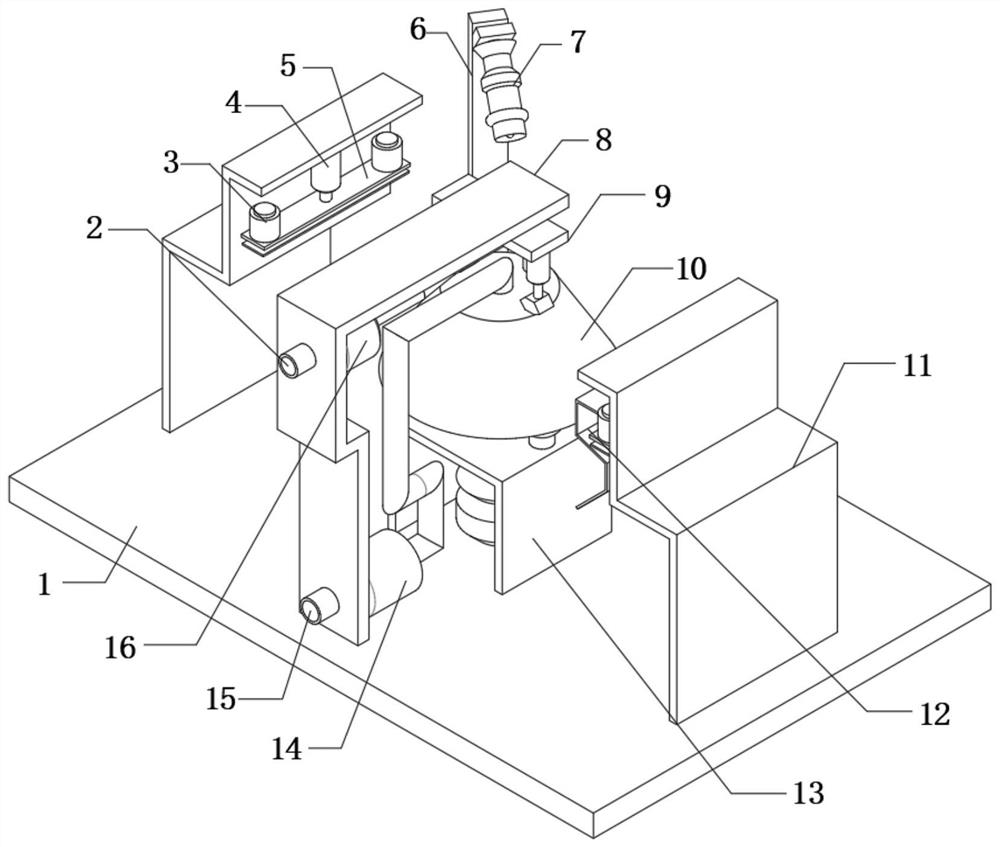

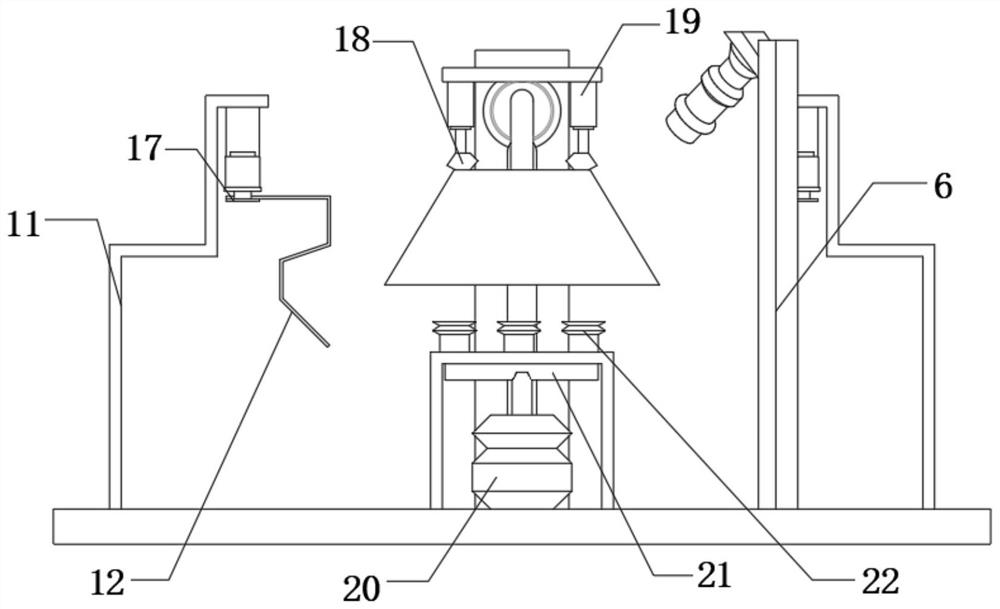

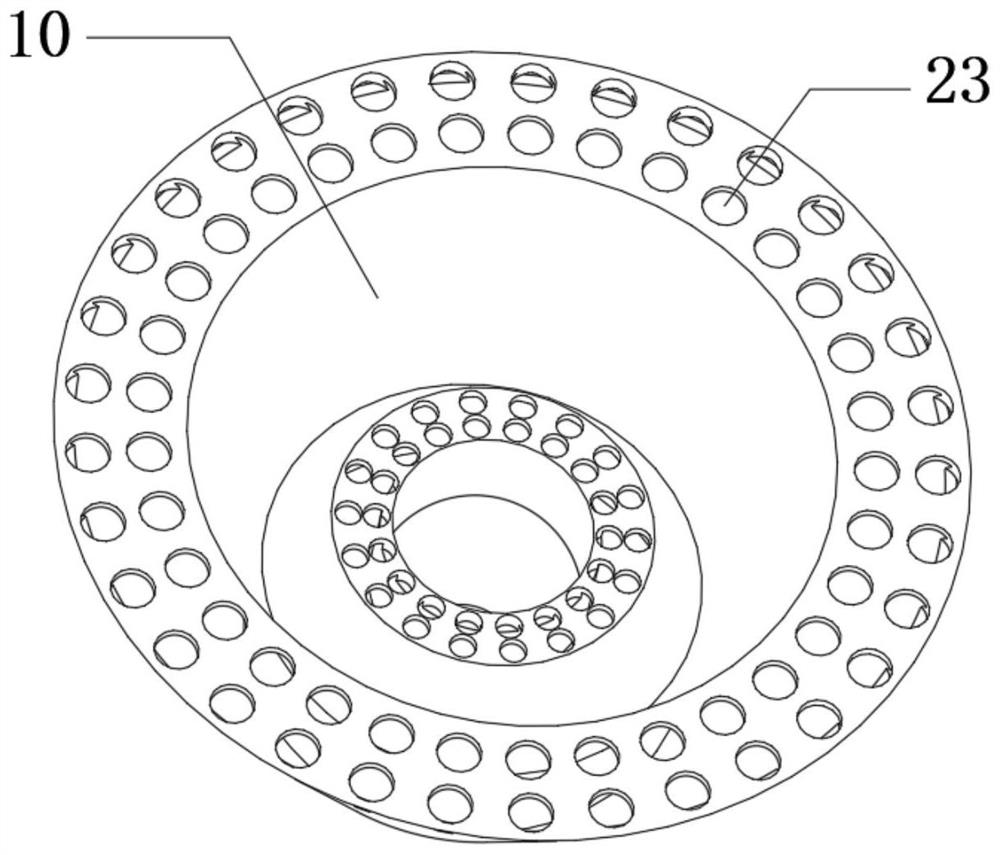

[0026] refer to Figure 1-3 , a small-diameter optical lens surface scratch detection device, including a base plate 1 and a blower 10, both ends of the top outer wall of the base plate 1 are fixedly connected with a support frame 11, and the outer walls of the support frame 11 are fixedly connected with a cylinder 4, The bottom outer walls of the two cylinders 4 are fixedly connected with an adjustment plate 5, and the top outer walls of the adjustment plate 5 are fixedly connected with two No. 1 hydraulic cylinders 3, and the bottom outer walls of the two No. 1 hydraulic cylinders 3 are fixedly connected with the same pressure plate 17 A water-absorbing tissue 12 is placed between the adjustment plate 5 and the pressure plate 17, the top outer wall of the bottom plate 1 is fixedly connected with a fixed frame 8, and one side of the outer wall of the fixed frame 8 is fixedly connected with an air pump 16, and the gas delivery end of the air pump 16 passes through a pipeline C...

Embodiment 2

[0035] refer to Figure 1-4 , a small-diameter optical lens surface scratch detection device, including a base plate 1 and a blower 10, both ends of the top outer wall of the base plate 1 are fixedly connected with a support frame 11, and the outer walls of the support frame 11 are fixedly connected with a cylinder 4, The bottom outer walls of the two cylinders 4 are fixedly connected with an adjustment plate 5, and the top outer walls of the adjustment plate 5 are fixedly connected with two No. 1 hydraulic cylinders 3, and the bottom outer walls of the two No. 1 hydraulic cylinders 3 are fixedly connected with the same pressure plate 17 A water-absorbing tissue 12 is placed between the adjustment plate 5 and the pressure plate 17, the top outer wall of the bottom plate 1 is fixedly connected with a fixed frame 8, and one side of the outer wall of the fixed frame 8 is fixedly connected with an air pump 16, and the gas delivery end of the air pump 16 passes through a pipeline C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com