Automated workflow based on identification of calibration samples

A workflow and sample technology, applied in the direction of dynamic tree, dynamic search technology, character and pattern recognition, etc., can solve the problems of lack of reproducibility of calibration measures, a lot of time and personnel expenditure, and take a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

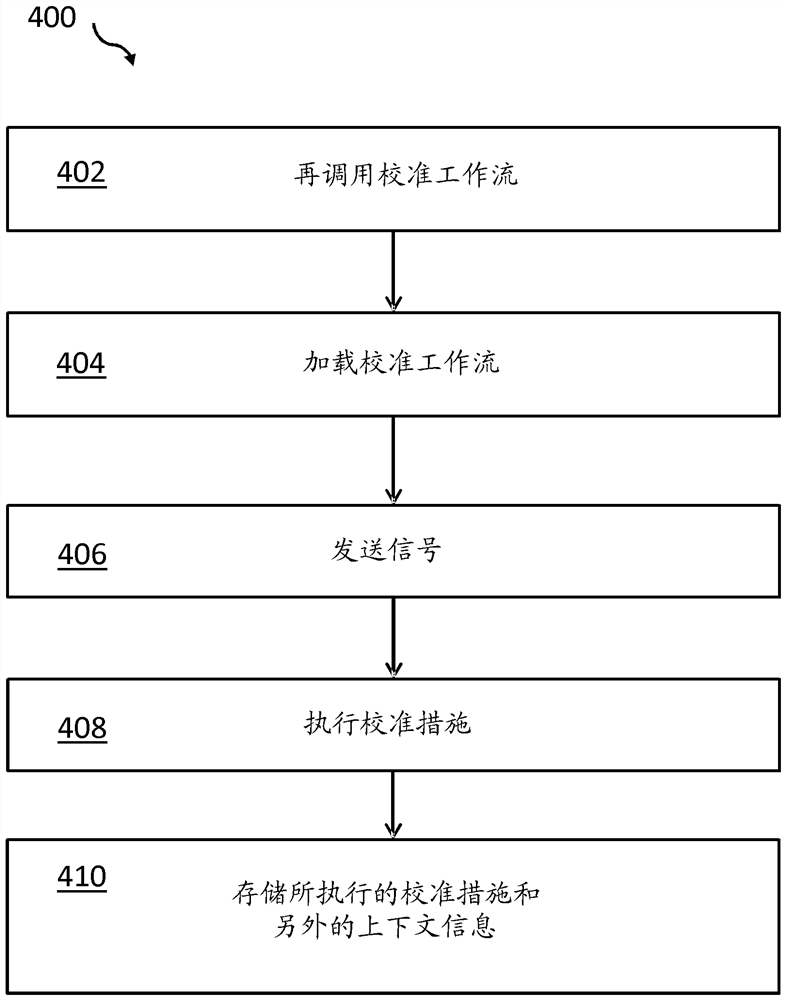

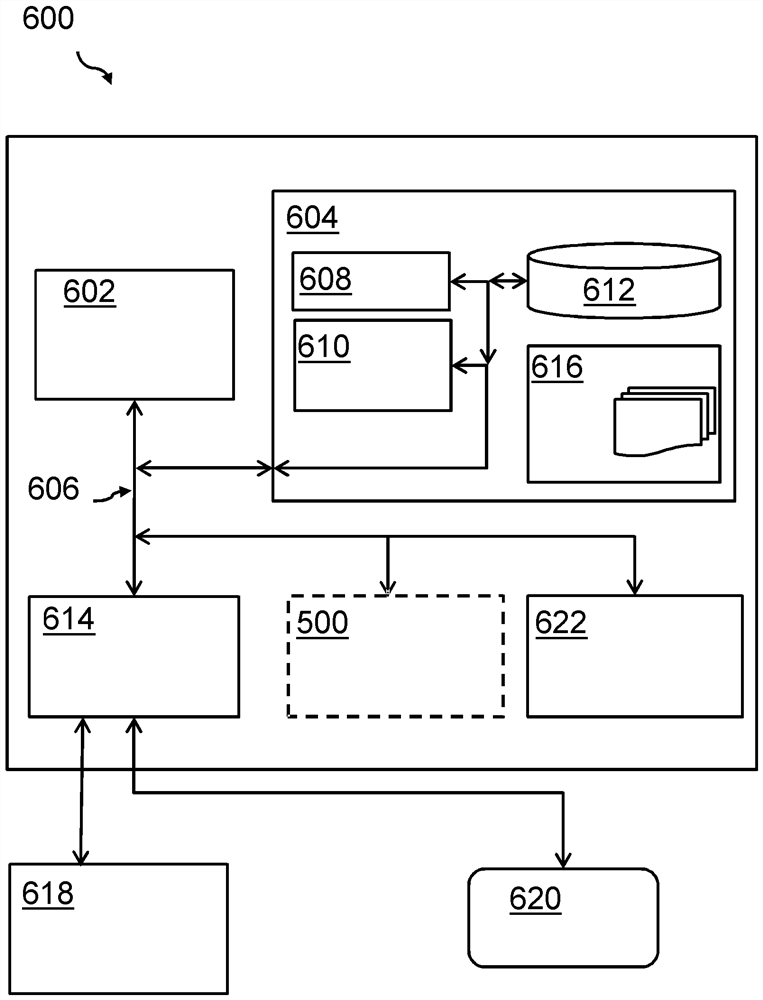

Method used

Image

Examples

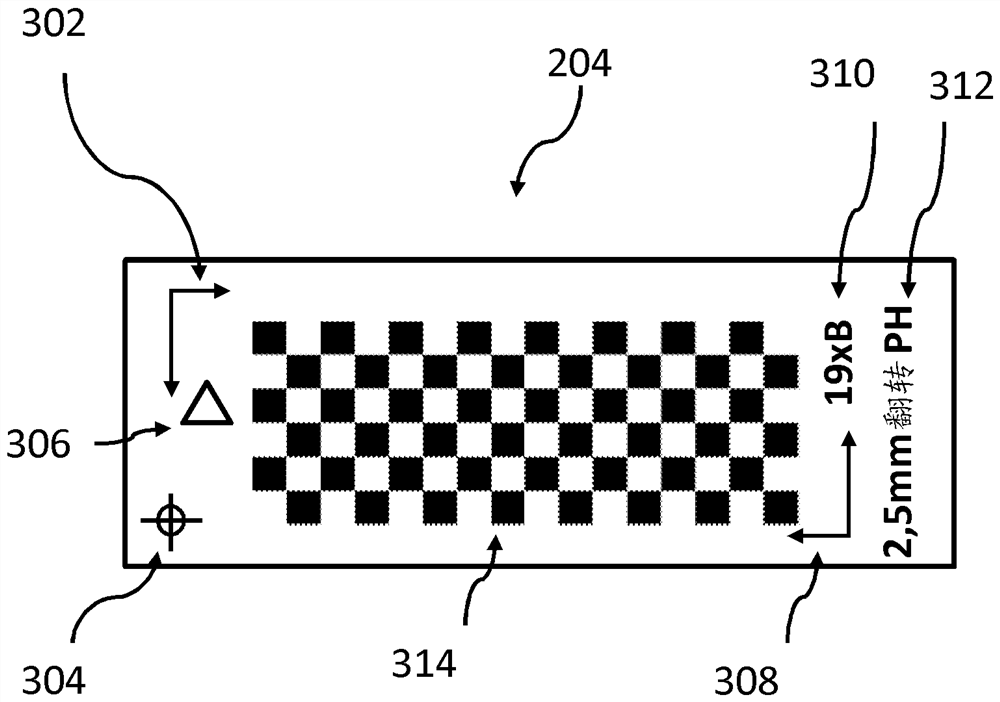

Embodiment Construction

[0060] In the context of this specification, conventions, terms and / or expressions should be understood as follows:

[0061] The term "microscope system" describes microscope systems that are used industrially, for example in the field of medicine, in the field of pharmacology, in the field of research or in the field of materials testing (eg quality assurance). As known, a microscope system includes components such as a displaceable sample stage with a sample carrier (typically displaceable in X, Y and Z directions), an illumination system, an imaging system with one or more objective lenses , whose imaging data are directed onto an image sensor or camera and are then available for further evaluation and possibly display by downstream units. Image data is available as pixel data. There may also be an overview camera.

[0062] The term "overview image" describes an image, recorded at relatively low resolution, of the portion of the sample stage of the microscope system with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com