System and method for testing thermal deformation of elastic winding drum

A thermal deformation, reeling technology, applied in the direction of measuring heat, using thermometers directly sensitive to heat/magnetic components, electric heating devices, etc. Fast and efficient implementation, low cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

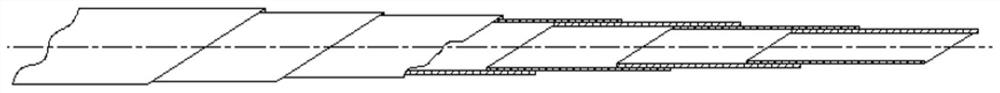

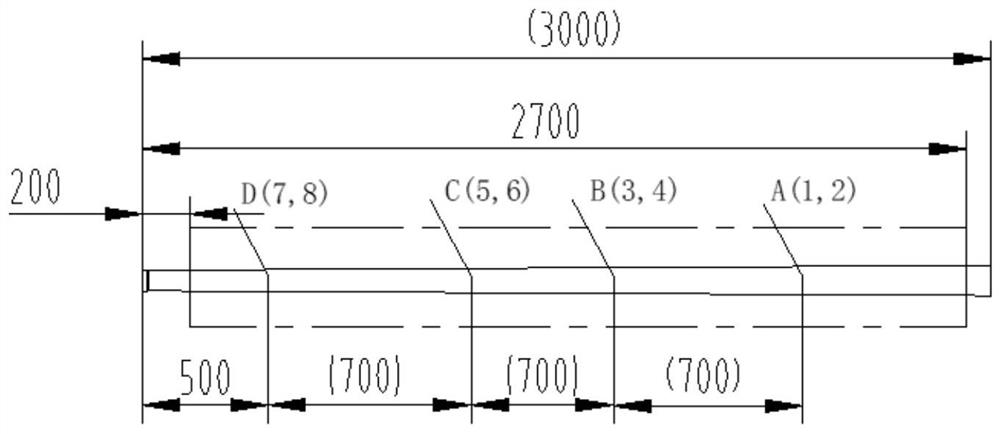

[0066] A plurality of temperature sensors are arranged on the reference roll, preferably, the temperature sensors are thermocouples. like figure 2 As shown, in this embodiment, 8 temperature sensors are set on the reference roll, and from the top to the bottom are the seventh thermocouple and the eighth thermocouple set at 500mm from the top, and the 8th thermocouple set at 1200mm from the top. The fifth thermocouple and the sixth thermocouple, the third thermocouple and the fourth thermocouple arranged at 1900 mm from the top, the first thermocouple and the second thermocouple arranged at 2600 mm from the top.

[0067] The two thermocouples at the same height are symmetrically arranged, that is, they are 180° apart on the circumference, and the thermocouples on two adjacent heights are 90° apart on the circumference. In actual use, the position and number of thermocouples installed on the reference reel can be increased or decreased according to actual needs. As the thermo...

Embodiment 2

[0069] The heating mechanism includes multiple sets of heating devices, such as Pic 4-1 As shown, each group of heating devices includes: frame cart 403 , lamp array frame 402 and lamp array 401 . The light array frame 402 is installed on the frame trolley 403 and can move up and down on the frame trolley 403 to adjust the height, and the light array 401 is installed on the light array frame. The bottom of the frame car 403 is equipped with lockable rollers (commercially available products can be used).

[0070] Specifically, a plurality of threaded holes arranged in the longitudinal direction are opened on the upper part of the frame cart 403, and a plurality of threaded holes arranged in the longitudinal direction are also opened on the light array frame 402, and the bolts are sequentially passed through the lamps. The threaded holes on the array frame and the frame car are connected with nuts, and the light array frame is fixed on the frame car through bolts, and the ligh...

Embodiment 3

[0075] The lamp array 401 includes a plurality of infrared lamps 4011 and a plurality of heat-insulating lampshades 4012, the infrared lamps 4011 correspond to the heat-insulating lampshades 4012 one by one, and the structure of one infrared lamp 4011 and one heat-insulating lampshade 4012 is as follows: Figure 4-2 shown. The heat-insulating lampshade 4012 is installed on the third column in the lamp array frame 402, and an infrared lamp 4011 is installed in front of the heat-insulating lampshade 4012, that is, the heat-insulating lampshade 4012 is located between the infrared lamp 4011 and Between the light array frames 402, the heat-insulating lampshade 4012 is arranged behind the lamp tubes to ensure that the lamp tubes only heat the front and not the rear light array frames, which also ensures that the lamp array frames will not be heated due to temperature rise. And deformation. Because the deformation of the lamp array frame will lead to the change of the position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com