Spray cooling system for battery pack

A technology of spray cooling and battery packs, which is applied in the direction of secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of spray devices not working properly, and achieve simple structure, good spray cooling effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

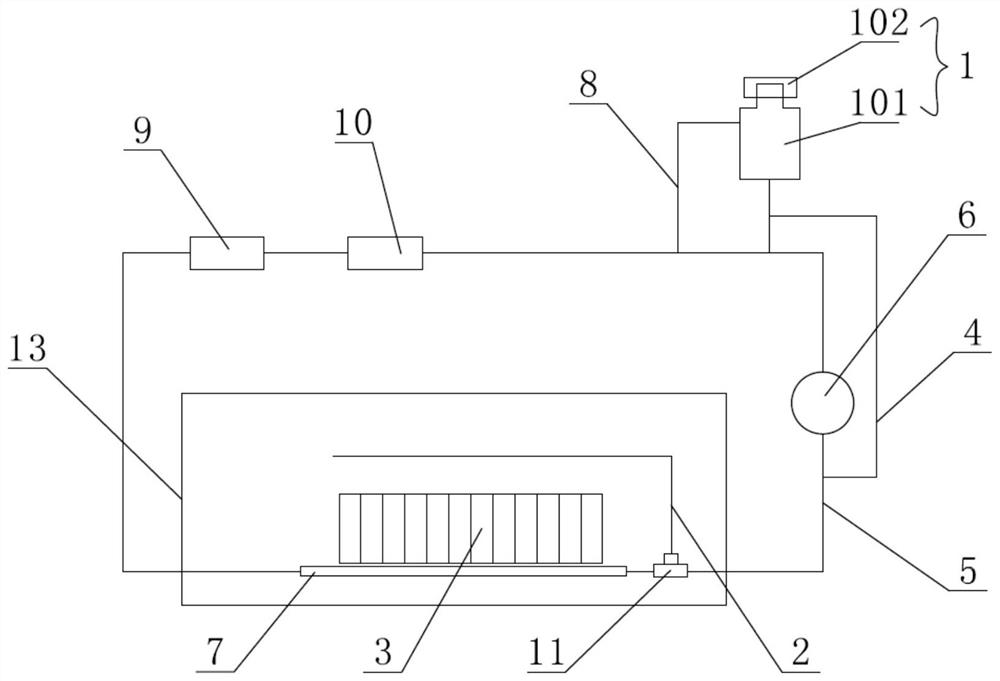

[0035] Such as figure 1 As shown, a spray cooling system for a battery pack includes a liquid storage device 1 for storing spray liquid, a spray device 2 for spraying and cooling the battery module 3, and a connection between the liquid storage device 1 and the spray device 2 The liquid supply pipe 5, the liquid driving device 6 that drives the spray liquid to the spray device 2. Wherein, the liquid driving device 2 is arranged on the liquid supply pipe 5, the liquid storage device 1 is arranged higher than the spray device 2, and the liquid storage device 1 can provide spray liquid for the spray device 2 through the artesian pipe 4 connected in parallel with the drive device.

[0036] The liquid storage device 1 is set higher than the spray device 2, and the spray liquid in the liquid storage device 1 has gravitational potential energy. Under the action of its own gravity, it enters the spraying device 2 to spray and cool down the thermally runaway battery module 3 . When t...

Embodiment 2

[0051] In the first embodiment, the spray liquid in the liquid storage device 1 is simultaneously used as cooling liquid to cool the battery module 3 . When an independent liquid storage device 1 is installed on the automobile, the liquid storage device 1 is no longer connected to the cooling circuit of the battery pack, and the liquid storage device 1 directly extends into the battery box 13 through the liquid supply pipe 5 to supply the spray device 2 spray liquid.

[0052] Such as Figure 5 As shown, the liquid storage device 1 in this embodiment is an independent liquid storage device 103, the independent liquid storage device 103 is directly connected to the spray device 2 through the liquid supply pipe 5, and the liquid driving device 6 is installed on the liquid supply pipe 5, and the liquid drives The device 6 drives the spray liquid in the liquid storage device 1 into the spray device 2 .

[0053] The spraying device 2 in this embodiment is the same as that in the f...

Embodiment 3

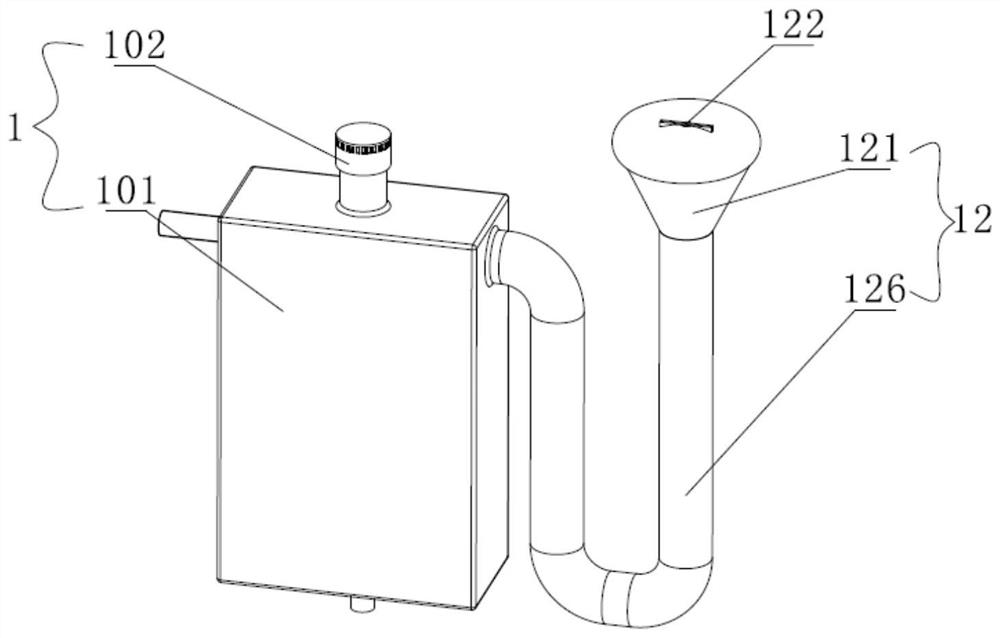

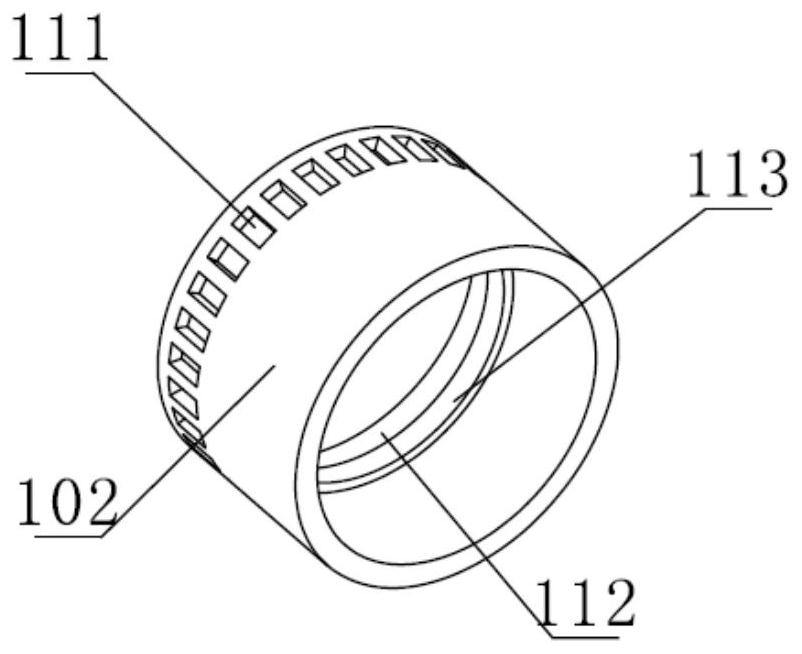

[0058] In this embodiment, the spraying method can be designed as the cooling and spraying common spraying liquid in the first embodiment, or it can be designed as a spraying method with an external independent spraying device 2 . The liquid storage device 1 in this embodiment also includes a kettle body 101 containing spray liquid and a cover body 102 with waterproof and breathable functions.

[0059] Such as figure 2 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that the liquid storage device 1 in this embodiment is connected to the water replenishment device 12, and the spray liquid is replenished to the liquid storage device 1 through the water replenishment device 12 to ensure There is enough spray liquid to cope with the thermal runaway phenomenon of the battery module 3 .

[0060] Moreover, the battery module 3 is sealed and installed inside the box body 13. When the thermal runaway of the battery pack is serious, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com