Ventilated moisture-proof power cabinet

A technology for power cabinets and ventilation devices, applied in the field of electric power, which can solve the problems of power consumption, high manufacturing costs, and increased hazards in the use of transformer boxes, and achieve the effects of avoiding energy loss and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

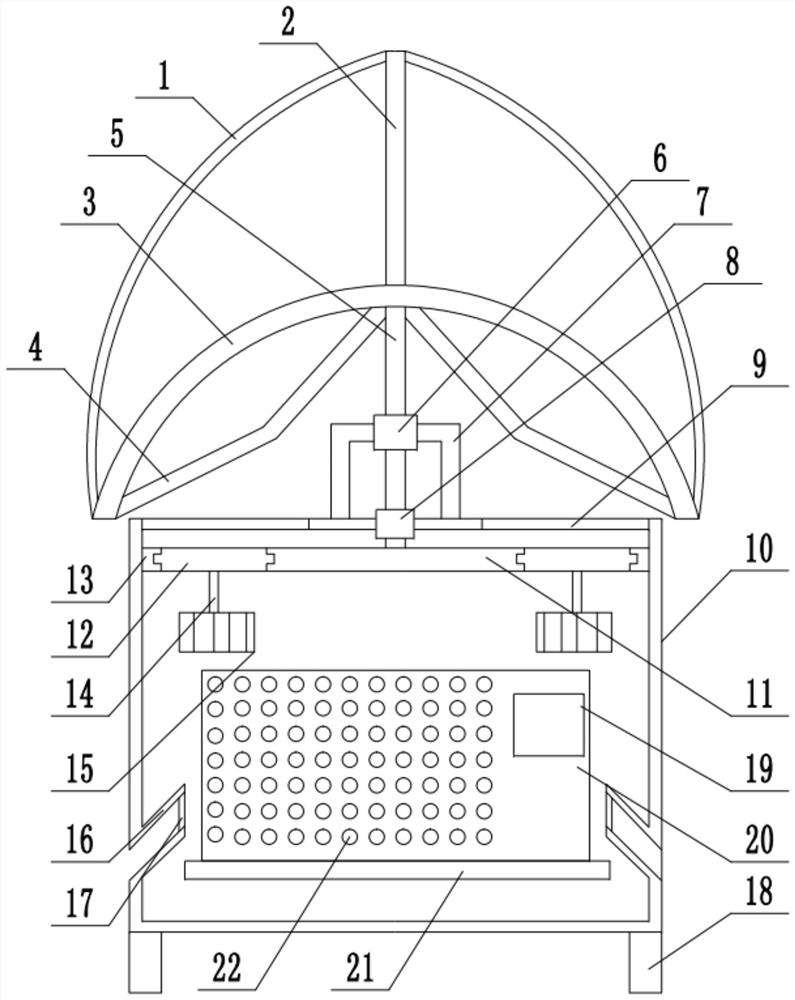

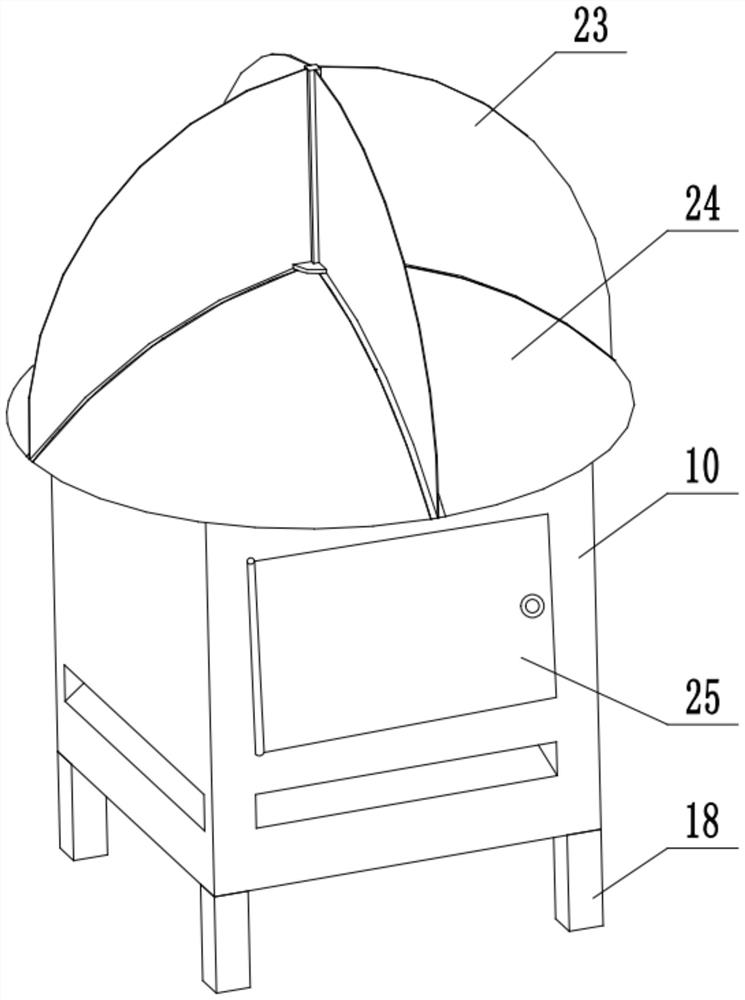

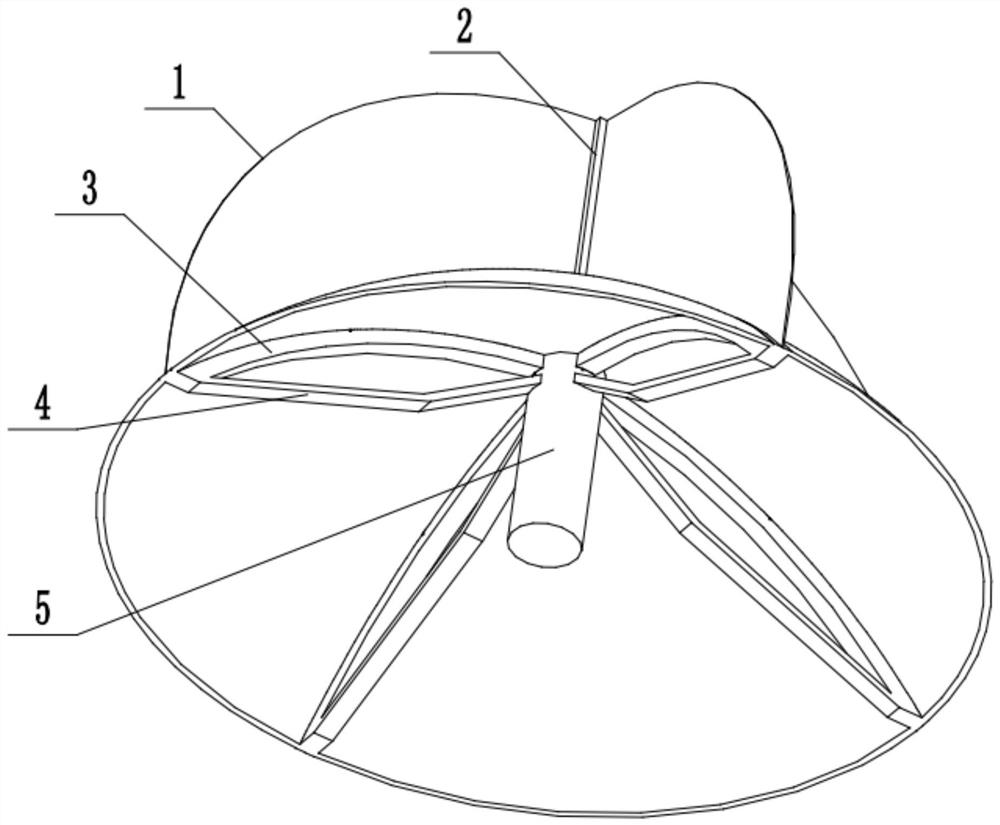

[0026] See Figure 1~3 In the embodiment of the present invention, a ventilated and moisture-proof power cabinet includes a rack 10, an air inlet 16 is installed on the outside of the rack 10 for the entry of outside air, and a second bearing 8 is installed at the upper middle of the rack 10, Used to install the rotating shaft 5, the middle of the second bearing 8 is installed with a rotating shaft 5, used to install the upper second bending rod 3, the upper part of the rotating shaft 5 is installed with at least three second bending rods 3, used to install rain film 24. A rain-shielding film 24 is covered between the second curved rods 3 to block rainwater when it rains. A support rod 2 is installed at the upper end of the rotating shaft 5 for installing the first curved rod 1, and the upper end of the support rod 2 is installed There are at least three first bending rods 1 for installing a wind-bearing film 23, and the first bending rods 1 are covered with a wind-bearing film...

Embodiment 2

[0031] See Figure 1~3 In an embodiment of the present invention, a ventilated and moisture-proof power cabinet includes a rack 10, an air inlet 16 is installed on the outside of the rack 10 for the entry of outside air, and a second bearing 8 is installed at the upper middle of the rack 10, Used to install the rotating shaft 5, the middle of the second bearing 8 is installed with the rotating shaft 5, used to install the upper second bending rod 3, the upper part of the rotating shaft 5 is installed with at least three second bending rods 3, used to install the rain film 24. There is a rain-shielding film 24 between the second bending rods 3, which is used to block rainwater when it rains. The upper end of the rotating shaft 5 is equipped with a support rod 2 for installing the first bending rod 1, and the upper end of the support rod 2 is installed There are at least three first bending rods 1 for installing a wind-bearing film 23, and the first bending rods 1 are covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com