Gas distribution drying furnace

A drying furnace and gas distribution technology, applied in drying, drying machines, drying chambers/containers, etc., can solve the problems of high power, short service life, high cost, etc., achieve long service life, low cost, and prevent condensation dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

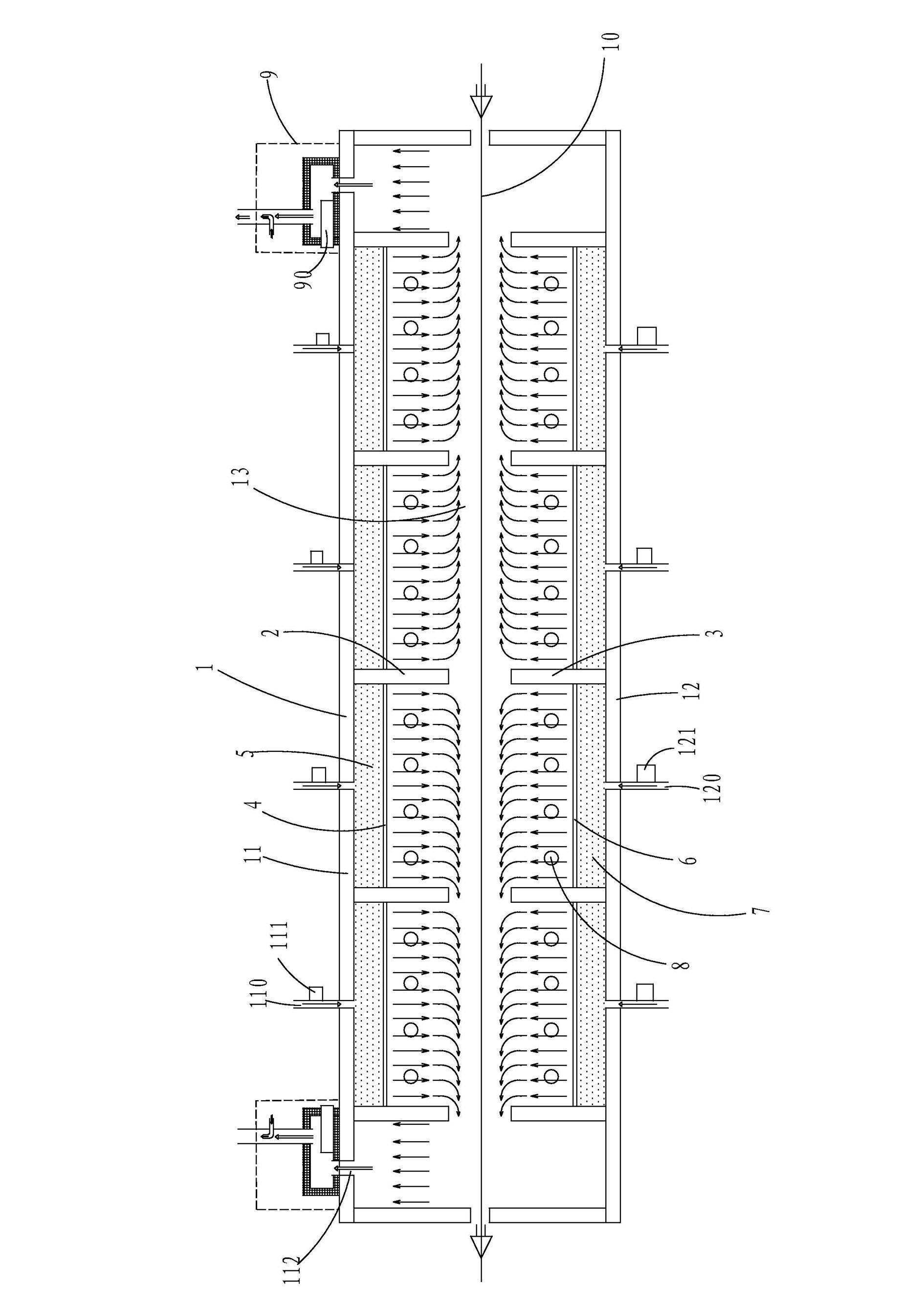

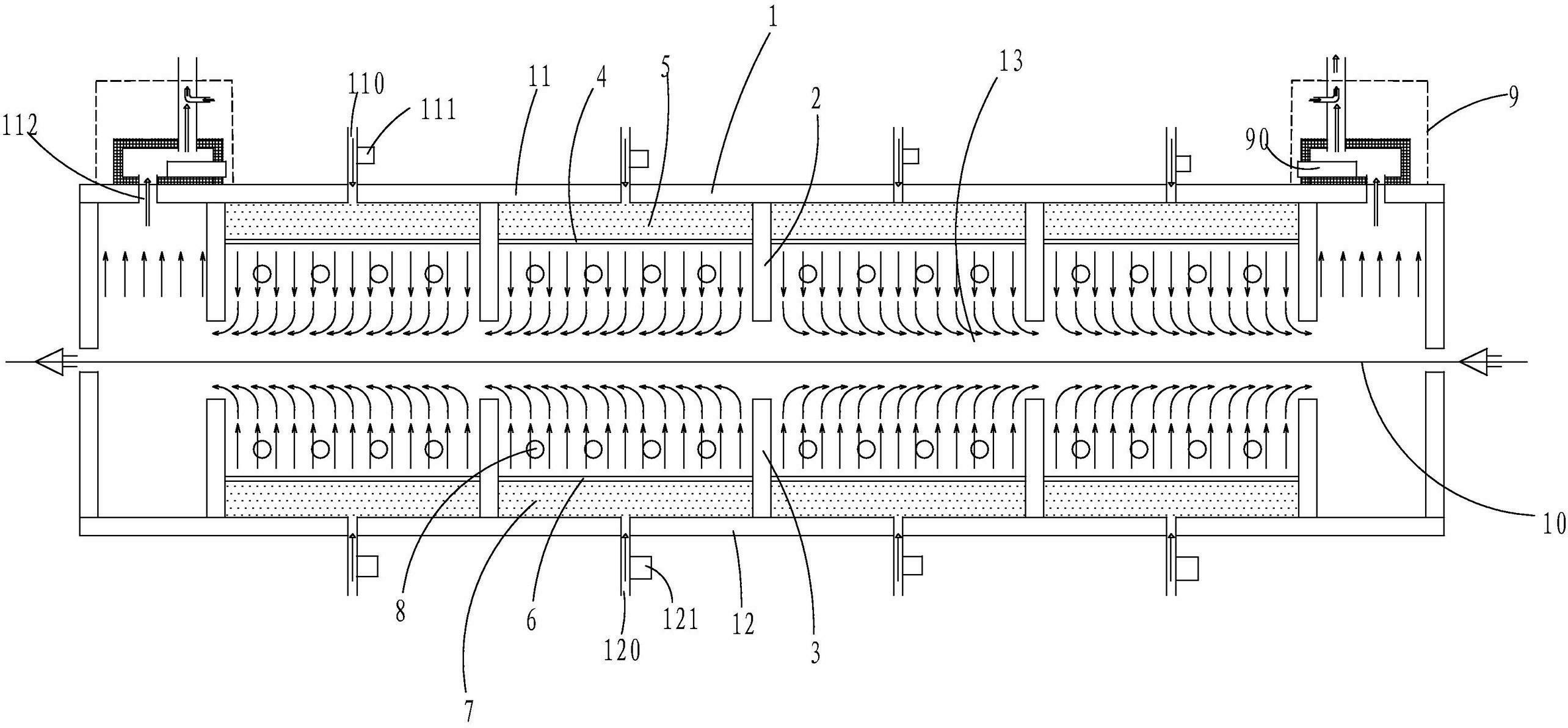

[0015] see figure 1 , a gas distribution drying furnace, comprising: a furnace body 1, the center of the furnace body 1 is provided with a drying channel 10, the furnace body 1 includes a top wall 11, a bottom wall 12, connected to the top wall 11 and the bottom wall The two end walls at both ends of the wall 12 and the two side walls connected to both sides of the top wall 11 and the bottom wall 12, the above-mentioned six walls surround and form a furnace chamber 13, and several groups of insulation partitions are arranged in the furnace chamber 13, and each group of insulation The partition includes a first thermal insulation partition 2 connected to the top wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com