Water condensation preventing microwave vacuum drier

A microwave vacuum drying and anti-condensation technology, used in drying chambers/containers, drying solid materials, local stirring dryers, etc., can solve problems such as prolonging drying time, reducing the temperature of dryers, and not being able to put in, and improving drying efficiency. , Slow down the drying speed and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

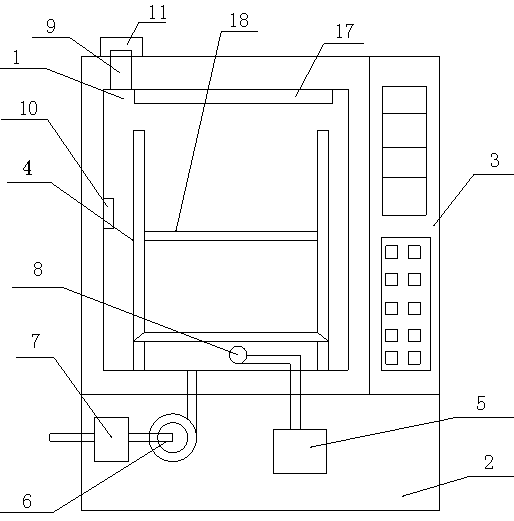

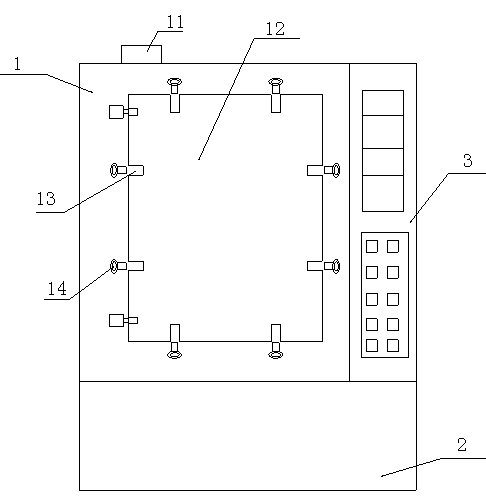

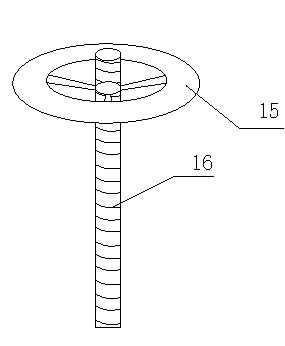

[0028] like figure 1 , figure 2 , image 3 As shown, a waterproof microwave vacuum dryer includes a sealed box 1, an electrical box 2 and a control box 3, the sealed box 1 is provided with a material rack 4, and the electrical box 2 is provided with a microwave generator 5, a vacuum pump 6 and the condenser 7, the microwave generator 5 is connected to the transmitter 8 in the sealed box 1 through a waveguide, the air suction port of the vacuum pump 6 is connected to the sealed box 1, and its gas outlet is connected to the condenser 7, and the outlet of the condenser 7 Connected to the outside, air inlet 9 is provided on the airtight box 1, and a heater 17 is arranged on the top of the airtight box 1, and the water vapor on the top is placed to condense and wet the articles again. A PLC controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com