Thermal barrier for downhole flasked electronics

A technology for downhole tools and components, which is applied in the field of heat-sensitive components, and can solve problems such as failure and inaccurate work of heat-sensitive electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

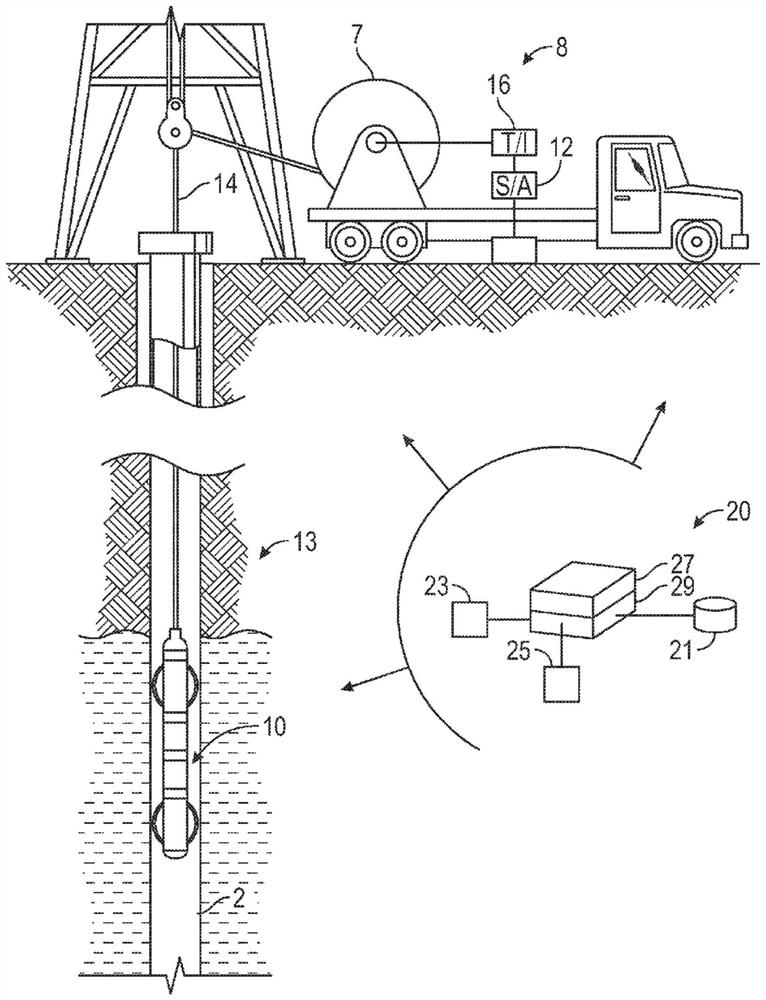

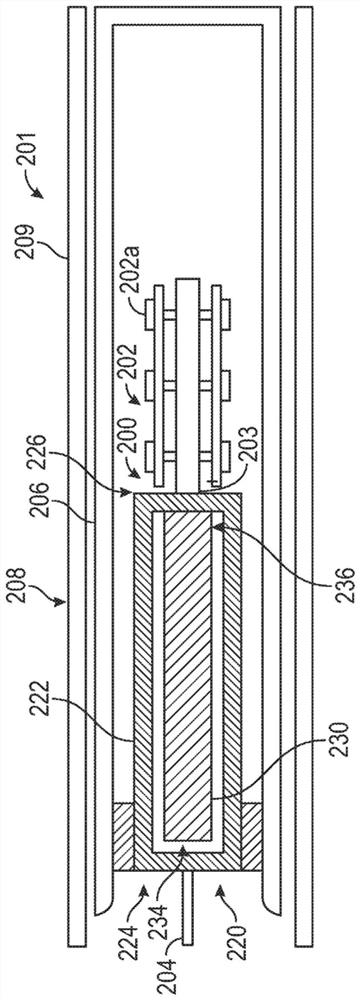

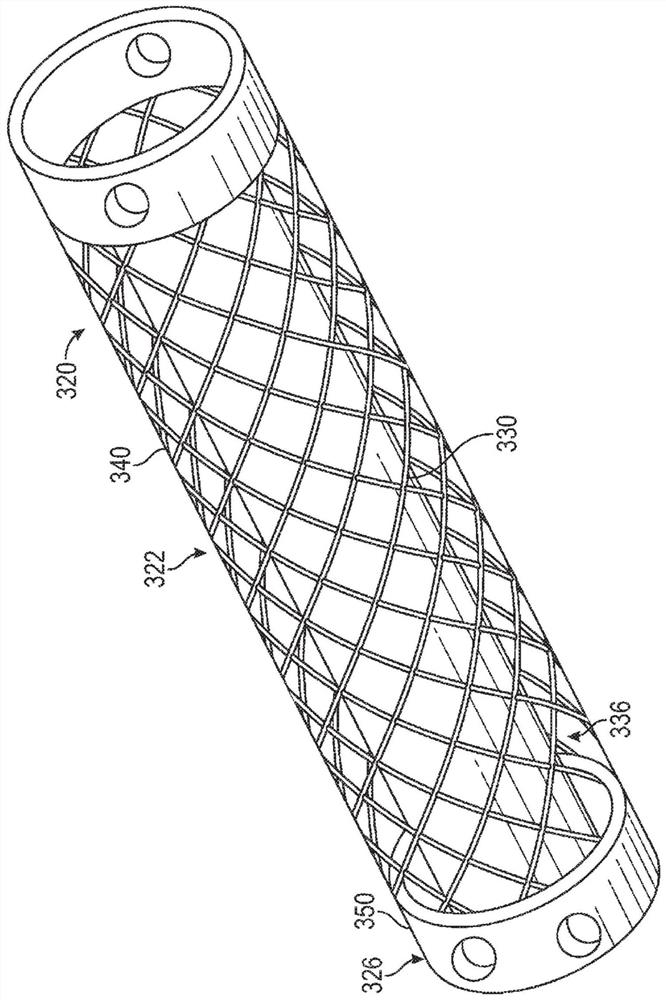

[0017] Aspects of the present disclosure relate to thermally isolating thermally sensitive components of a downhole tool from a high temperature environment. The present disclosure relates to apparatus and methods for isolating thermally sensitive components from the wellbore environment and / or heat generated by downhole components. In particular, aspects of the present disclosure relate to flask-type insulation systems. Aspects include devices for research boreholes or other use in boreholes intersecting formations.

[0018] Aspects of the present disclosure provide novel ways to thermally isolate electronics inside a downhole drilling or logging tool. Embodiments disclosed herein may include an assembly associated with a downhole tool and configured to thermally isolate heat sensitive components. The assembly may include: a thermal housing; a base within the thermal housing; at least one thermally sensitive component mounted on the base; and an insulating support connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com