A floor polishing machine

A grinding machine and machine base technology, which is applied in the direction of grinding frames, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as damage to grinding blocks, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

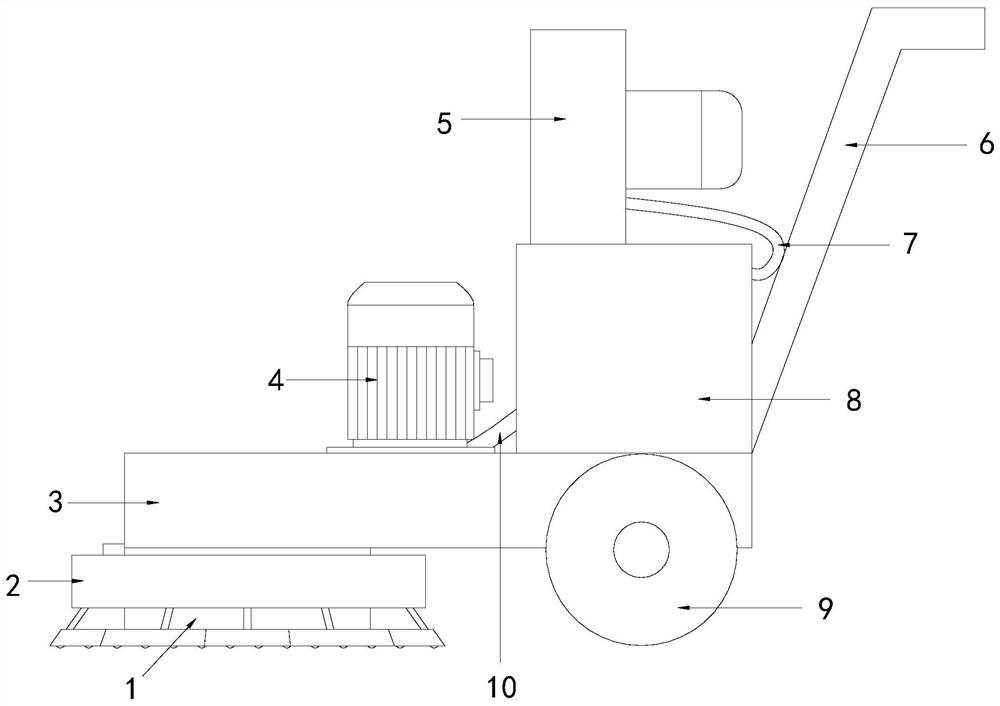

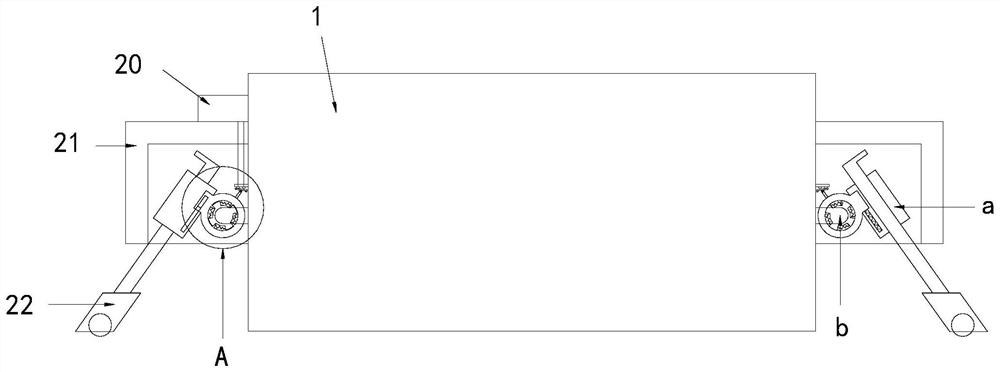

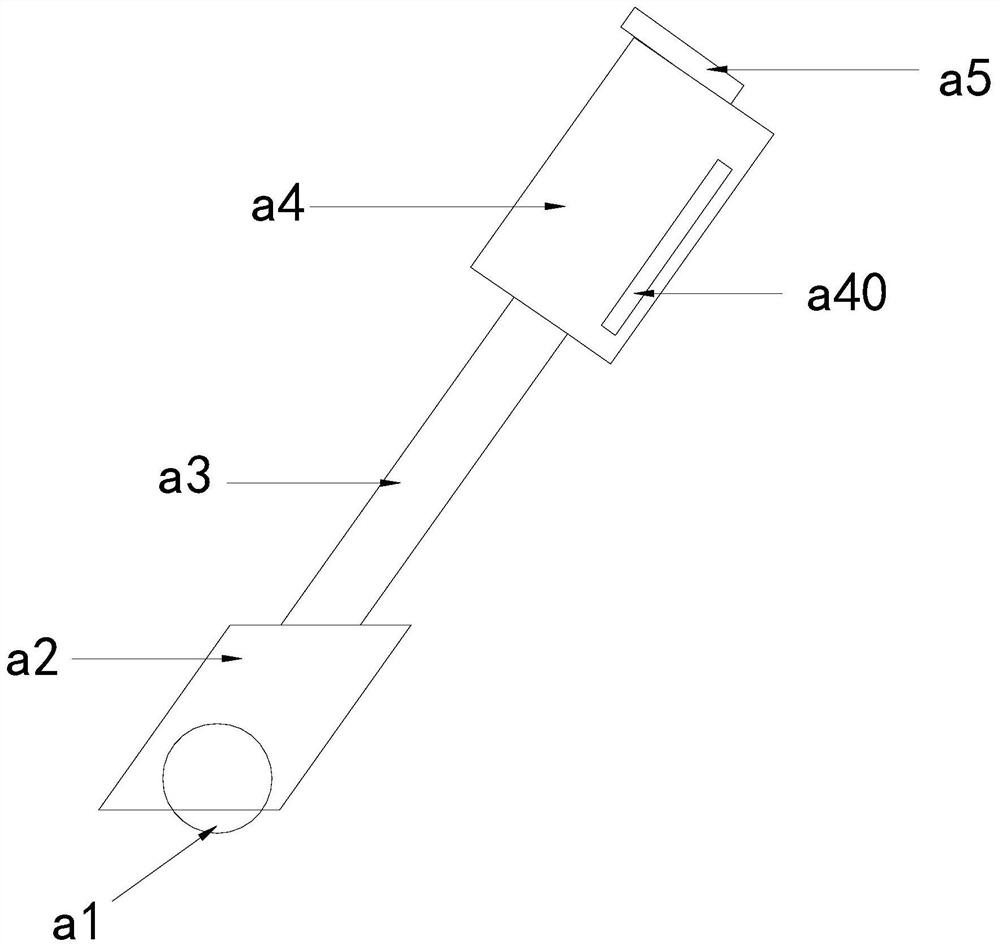

[0028] see Figure 1-5 , the present invention provides a floor polisher technical solution: its structure includes a vacuum cover 1, a reminder device 2, a machine base 3, a motor 4, a fan 5, a handrail 6, a first air duct 7, a dust box 8, Moving wheel 9, the second air duct 10, one end of the bottom of the base 3 is connected with a dust cover 1, the dust cover 1 is provided with a grinding block, and the other end of the base 3 is equipped with a moving wheel 9, so Described handrail 6 is located at the top of moving wheel 9 and is connected with support 3, and described support 3 is connected with motor 4, dust collection box 8, and described motor 4 is connected with grinding block transmission, and described dust collection box 8 passes through The second air duct 10 communicates with the dust collection hood 1, the fan 5 is connected to the top of the dust collection box 8 and communicates with the dust collection box 8 through the first air duct 7, and a reminder devic...

Embodiment 2

[0031] see Figure 1-5, the present invention provides a floor polisher technical solution: its structure includes a vacuum cover 1, a reminder device 2, a machine base 3, a motor 4, a fan 5, a handrail 6, a first air duct 7, a dust box 8, Moving wheel 9, the second air duct 10, one end of the bottom of the base 3 is connected with a dust cover 1, the dust cover 1 is provided with a grinding block, and the other end of the base 3 is equipped with a moving wheel 9, so Described handrail 6 is located at the top of moving wheel 9 and is connected with support 3, and described support 3 is connected with motor 4, dust collection box 8, and described motor 4 is connected with grinding block transmission, and described dust collection box 8 passes through The second air duct 10 communicates with the dust collection hood 1, the fan 5 is connected to the top of the dust collection box 8 and communicates with the dust collection box 8 through the first air duct 7, and a reminder device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com