Special inspection robot for electric power distribution cabinet

A technology for inspection robots and power distribution cabinets, applied in the direction of manipulators, electrical components, switchgear, etc., can solve problems such as collisions, failures of electronic devices and control modules, and impact on inspection work, and achieve easy disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

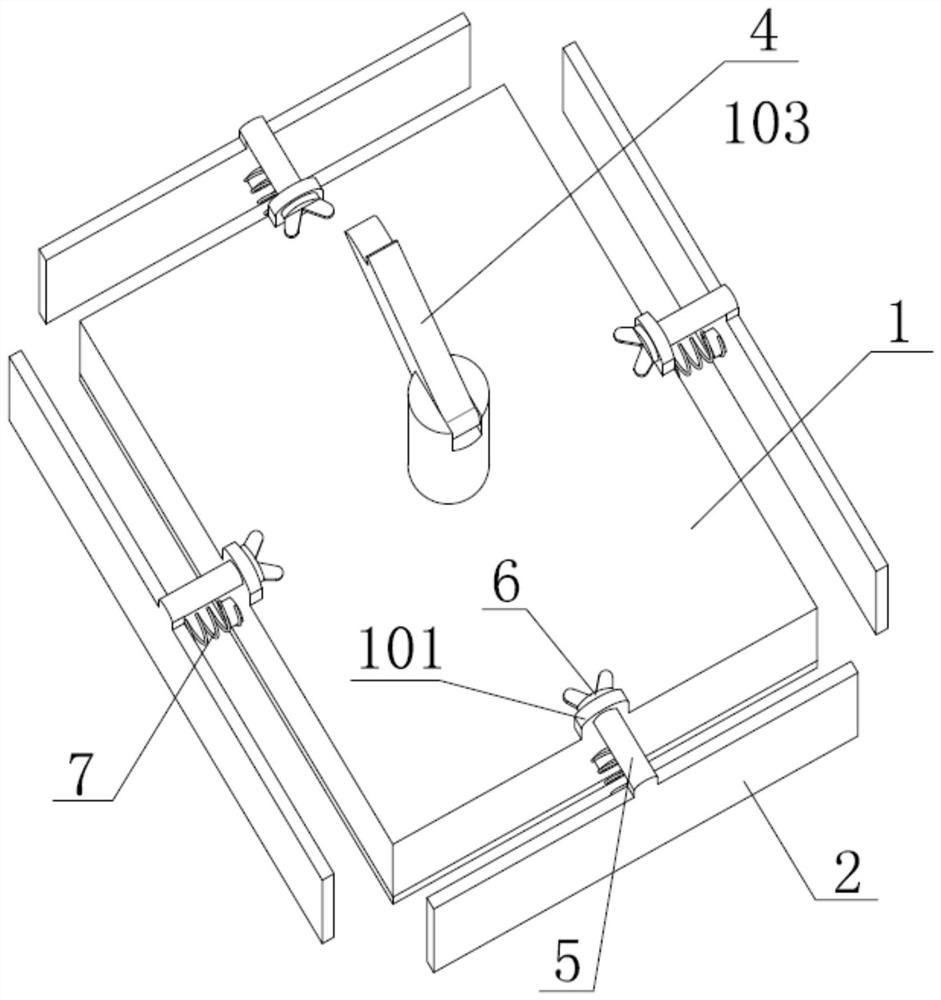

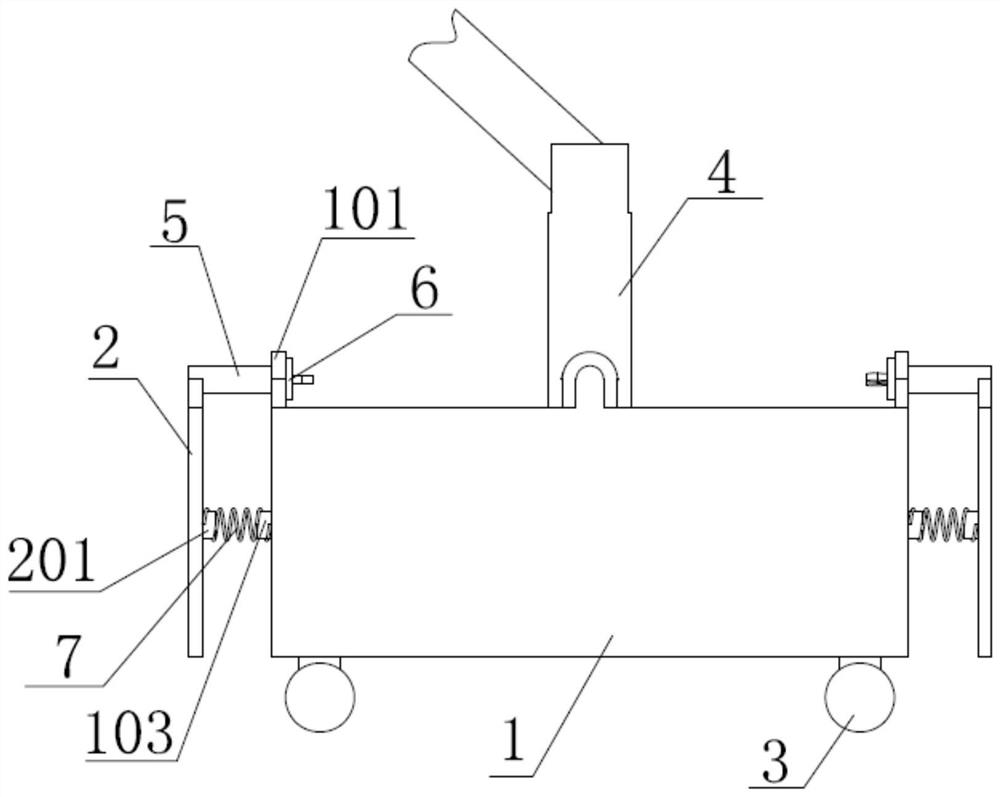

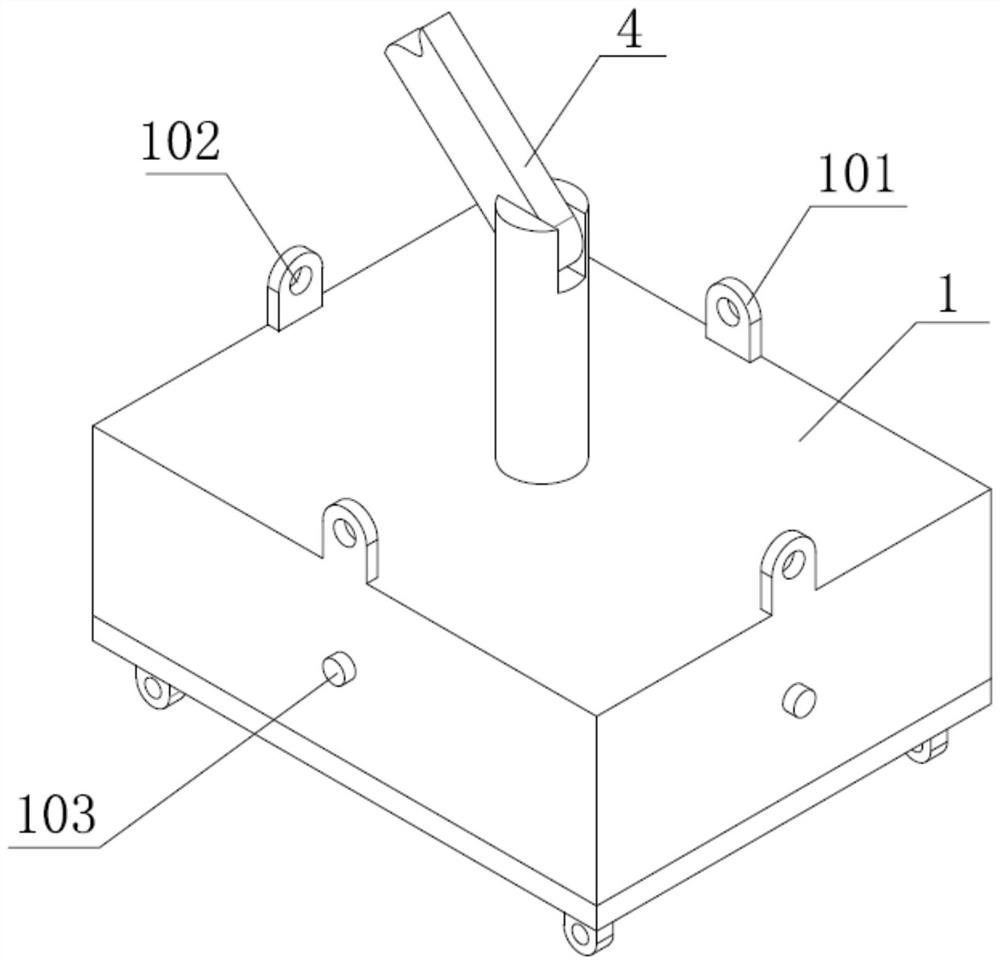

[0027] Such as Figure 1-Figure 4 As shown, a special inspection robot for power distribution cabinets, including a main control box 1, the four sides of the main control box 1 are connected with anti-collision plates 2, and the four corners of the bottom of the main control box 1 are all rotated Connected with a moving wheel 3, the moving wheel 3 is a moving steering wheel controlled by a motor. The top of the main control box 1 is provided with a mechanical arm 4. The mechanical arm 4 adopts a six-degree-of-freedom mechanical arm. The equipment for testing in the electric cabinet, such as infrared cameras, multimeters, etc., is fixed with connecting plates 101 on the four sides of the main control box 1, and the connecting plates are provided with sliding holes 102, and the top of the anti-collision plate 2 is fixedly connected with sliding holes. The sliding rod 5 adapted to the hole 102, the insertion end of the sliding rod 5 passes through the sliding hole 102, the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com